Immersion type 3D printing platform

A 3D printing and immersive technology, applied in processing platforms/substrates, additive processing, etc., can solve problems such as accelerated equipment wear and aging, high sealing requirements, and difficulty in taking models, so as to reduce performance requirements and save Model support, the effect of avoiding molding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a specific embodiment will be described in detail with reference to the accompanying drawings.

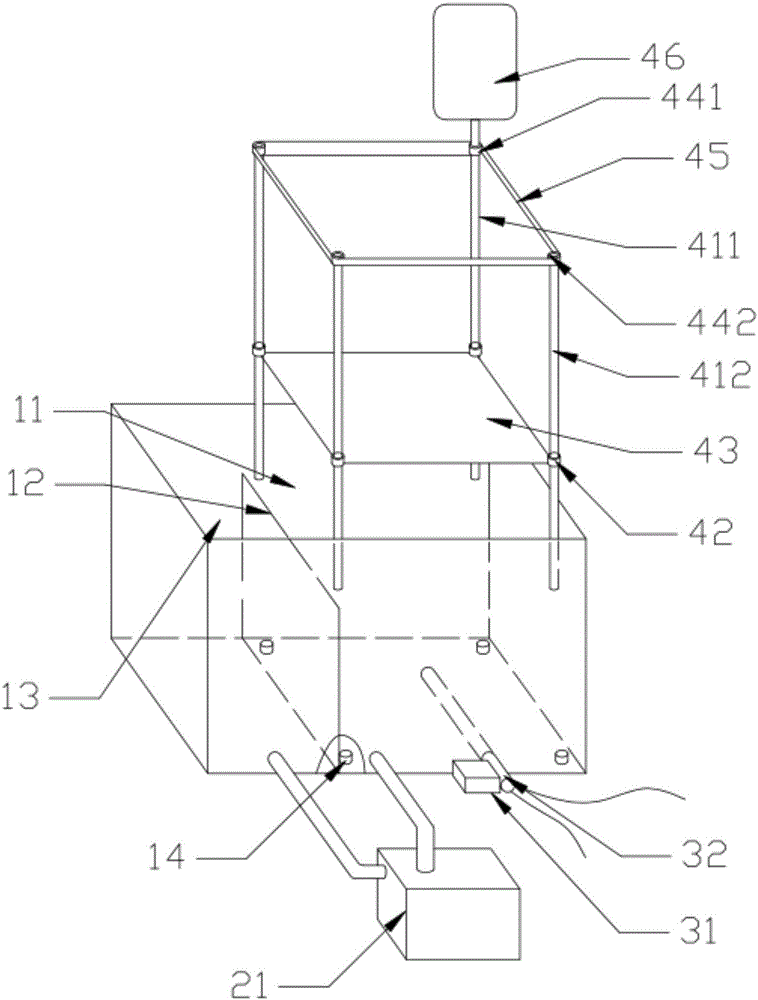

[0022] In order to solve the above-mentioned problems, the present invention provides an immersive 3D printing platform, which includes a liquid storage part containing liquid, a platform lifting part, a liquid circulation part and a heating part; the platform lifting part is placed inside the liquid storage part, so The liquid circulation part communicates with the liquid storage part, and the heating part is insulated and connected to the liquid storage part. The heating part generates heat and keeps the liquid in the liquid storage part at a temperature suitable for eliminating the internal stress of the material. The platform lifting part carries the printed model and controls the degree of contact between the model and the liquid. The liquid circulation part circulates the liquid in the liquid storage part, thereby ensuring uniform temperature of the liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com