A polymer modified asphalt waterproof membrane for road and bridge and preparation method thereof

A kind of asphalt waterproof membrane and high polymer modification technology, which is applied to asphalt coatings, chemical instruments and methods, bridges, etc., can solve problems such as difficulty in meeting actual needs, slow construction progress at construction sites, and poor oiliness during construction. Small attenuation, improved service life, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

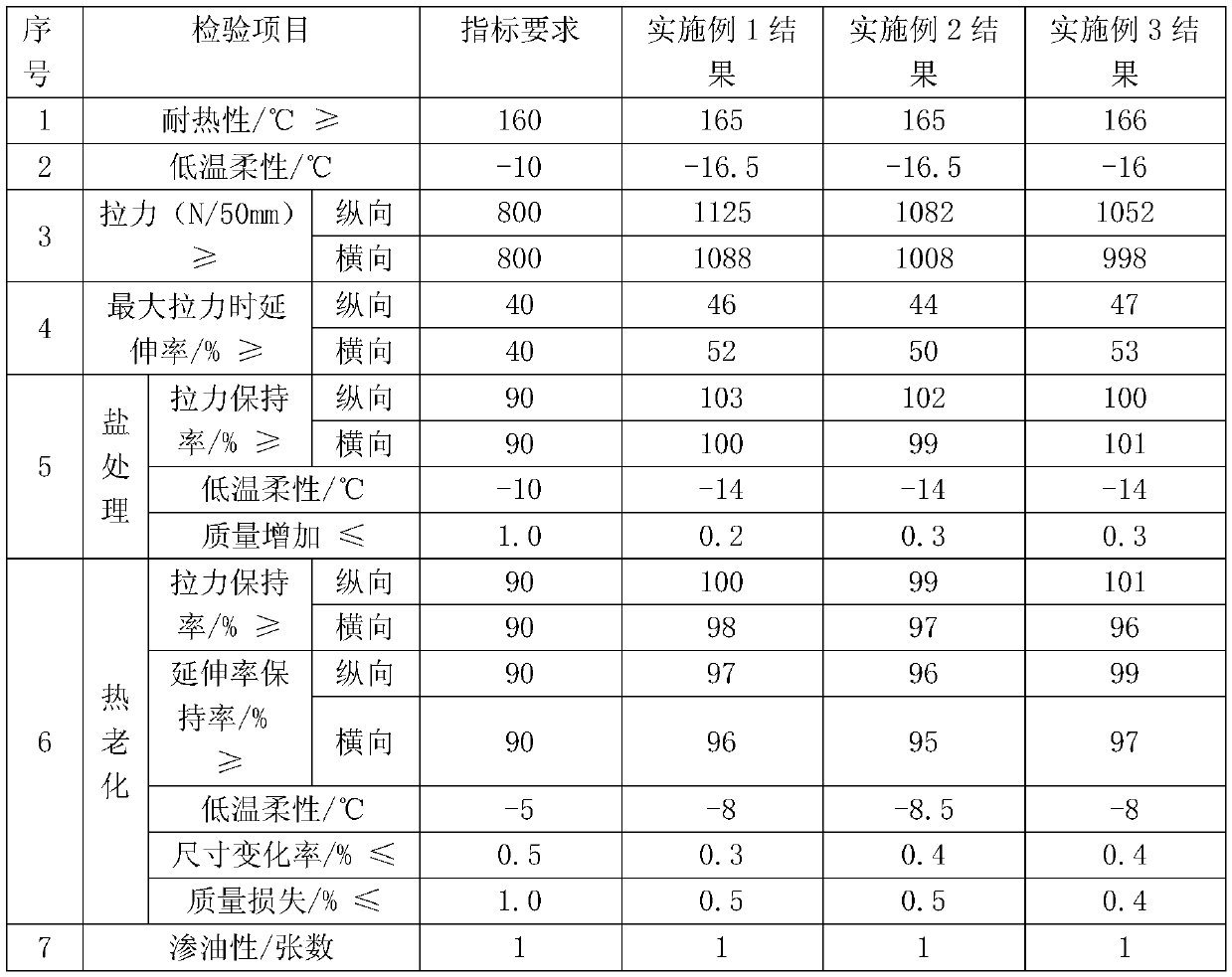

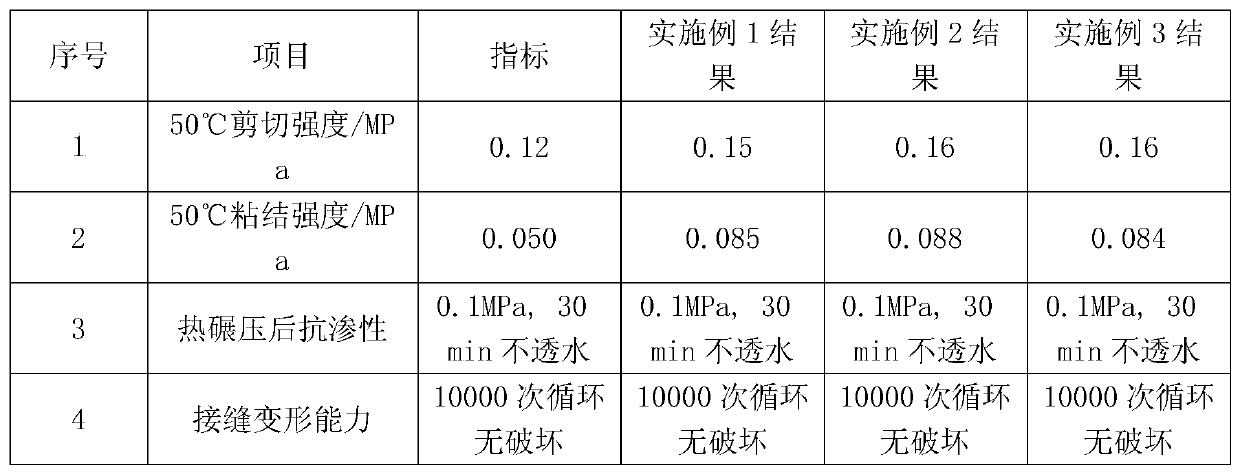

Embodiment 1

[0024] 1. Formula of modified asphalt

[0025] 2600kg 90# asphalt, 1000kg 200# asphalt, 425kg IPP, 80kg SBS, 350kg APAO, 300kg high temperature modifier, 1100kg modified powder, 900kg heavy calcium.

[0026] 2. Preparation of modified asphalt

[0027] (1) Pour in 2600kg 90# asphalt and 1000kg 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0028] (2) Add 425kg IPP and 80kg SBS to swell at 150-170°C for 1-2 hours.

[0029] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0030] (4) Add 350kg APAO and stir for 30min.

[0031] (5) Add 300kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0032] (6) Add 1100kg of modified powder and 900kg of heavy calcium, and stir at high speed for 60-90min.

[0033] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0034] 3. High polymer modified asphalt waterproof membrane fo...

Embodiment 2

[0038] 1. Formula of modified asphalt

[0039] 2650kg 90# asphalt, 950kg 200# asphalt, 425kg IPP, 70kg SBS, 340kg APAO, 250kg high temperature modifier, 1050kg modified powder, 900kg heavy calcium.

[0040] 2. Preparation of modified asphalt for road and bridge

[0041] (1) Pour in 2650kg of 90# asphalt and 950kg of 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0042] (2) Add 425kg IPP and 70kg SBS to swell for 1-2 hours when the temperature is 150-170°C.

[0043] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0044] (4) Add 340kg APAO and stir for 30min.

[0045] (5) Add 250kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0046] (6) Add 1050kg of modified powder and 900kg of heavy calcium, and stir at high speed for 60-90min.

[0047] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0048] 3. High po...

Embodiment 3

[0052] 1. Formula of modified asphalt

[0053] 2900kg 90# asphalt, 950kg 200# asphalt, 425kg IPP, 100kg SBS, 350kg APAO, 200kg high temperature modifier, 1100kg modified powder, 1000kg heavy calcium.

[0054] 2. Preparation of modified asphalt for road and bridge

[0055] (1) Pour in 2900kg 90# asphalt and 950kg 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0056] (2) Add 425kg IPP and 100kg SBS to swell at 150-170°C for 1-2 hours.

[0057] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0058] (4) Add 350kg APAO and stir for 30min.

[0059] (5) Add 200kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0060] (6) Add 1100kg of modified powder and 1000kg of heavy calcium, and stir at high speed for 60-90min.

[0061] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0062] 3. High polymer modified asphalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com