Balance shaft support for heavy commercial vehicles

A technology for balance shaft brackets and commercial vehicles, which is applied to suspensions, vehicle components, interconnection systems, etc., can solve the problem of insufficient bearing capacity of the longitudinal beam width connection holes and cross beam connection holes of the balance shaft bracket, the cumbersome structure of the balance shaft bracket, and the system Reduce the bearing capacity and other problems, achieve the effect of light weight, improve the bearing strength of the bolt, and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

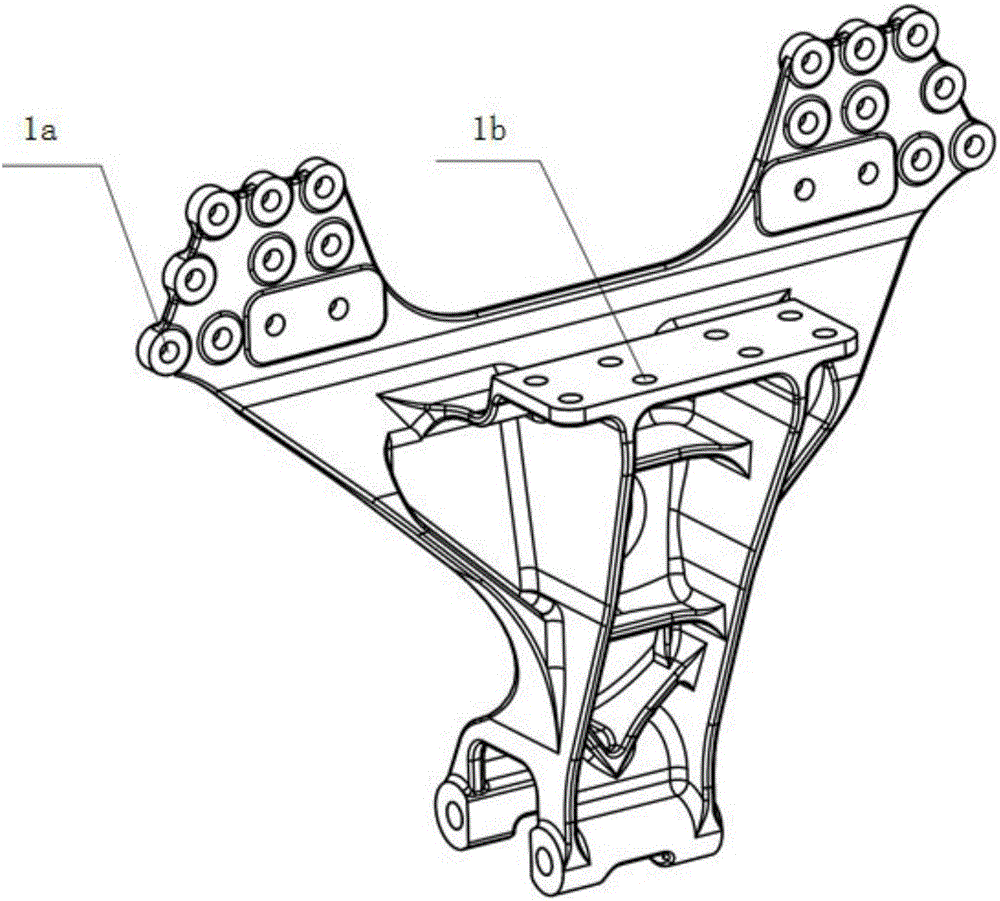

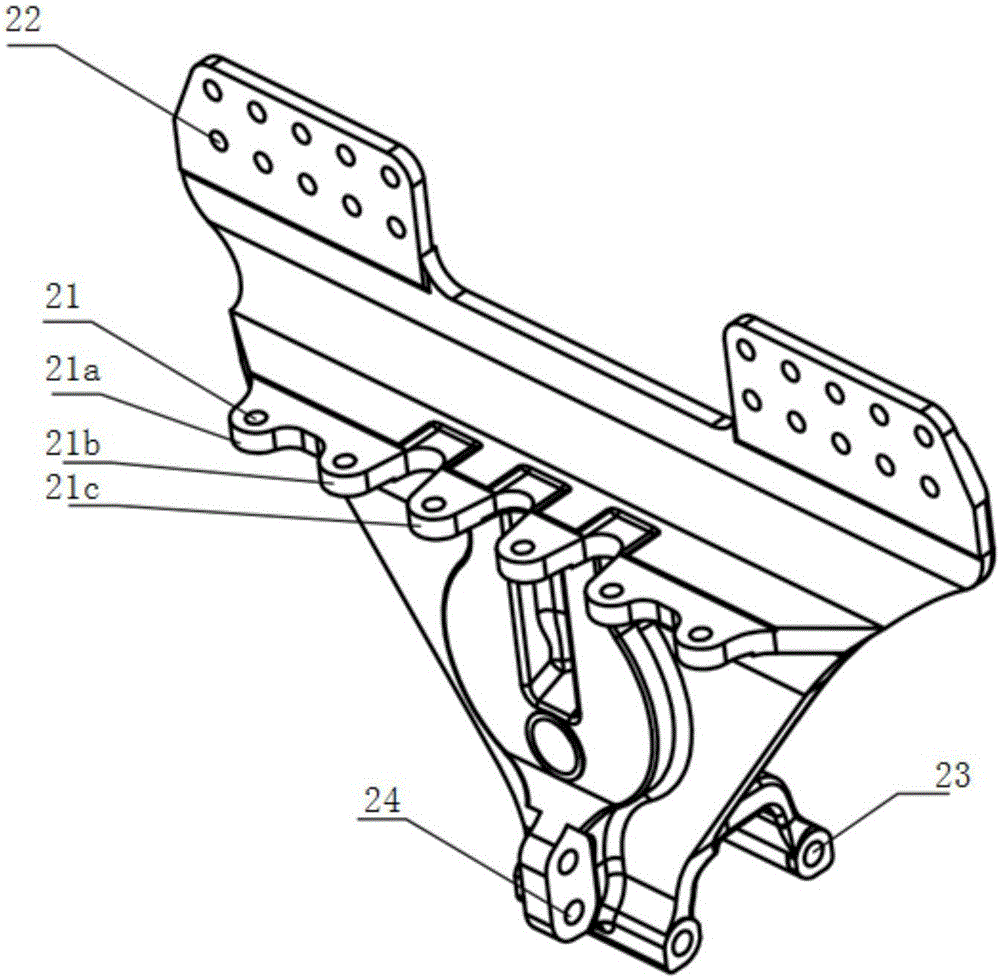

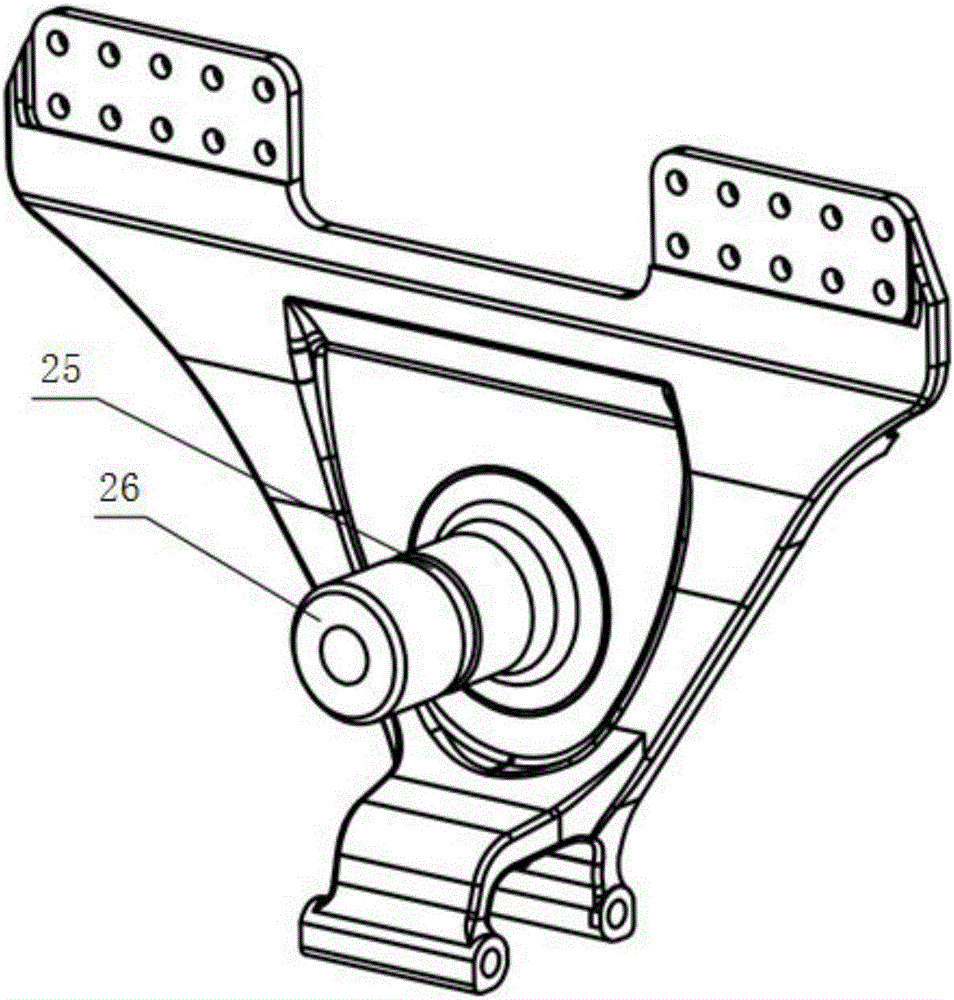

[0031] The invention discloses a balance shaft support for a heavy-duty commercial vehicle. The balance shaft support is symmetrically arranged along the vehicle frame left and right. Such as figure 2 As shown, the main body of the balance shaft bracket in the present invention is an inverted triangular plate-shaped structure, and an outer edge structure is arranged inwardly perpendicular to the main body of the balance shaft bracket on the top of the balance shaft bracket body, and the outer edge structure is the top surface of the balance shaft bracket , there is a row of first connecting holes 21 on the top surface, the first connecting holes 21 are evenly arranged in the shape of "one", and the first connecting holes 21 are used to connect with the frame beam; in this In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com