Water spraying propeller

A technology of water jet propulsion and propulsion, which is applied to ship propulsion, propulsion components, propulsion device engines, etc., which can solve problems such as bottom suction and beaching, troublesome operation, etc., and achieve the effects of convenient operation, low cost, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

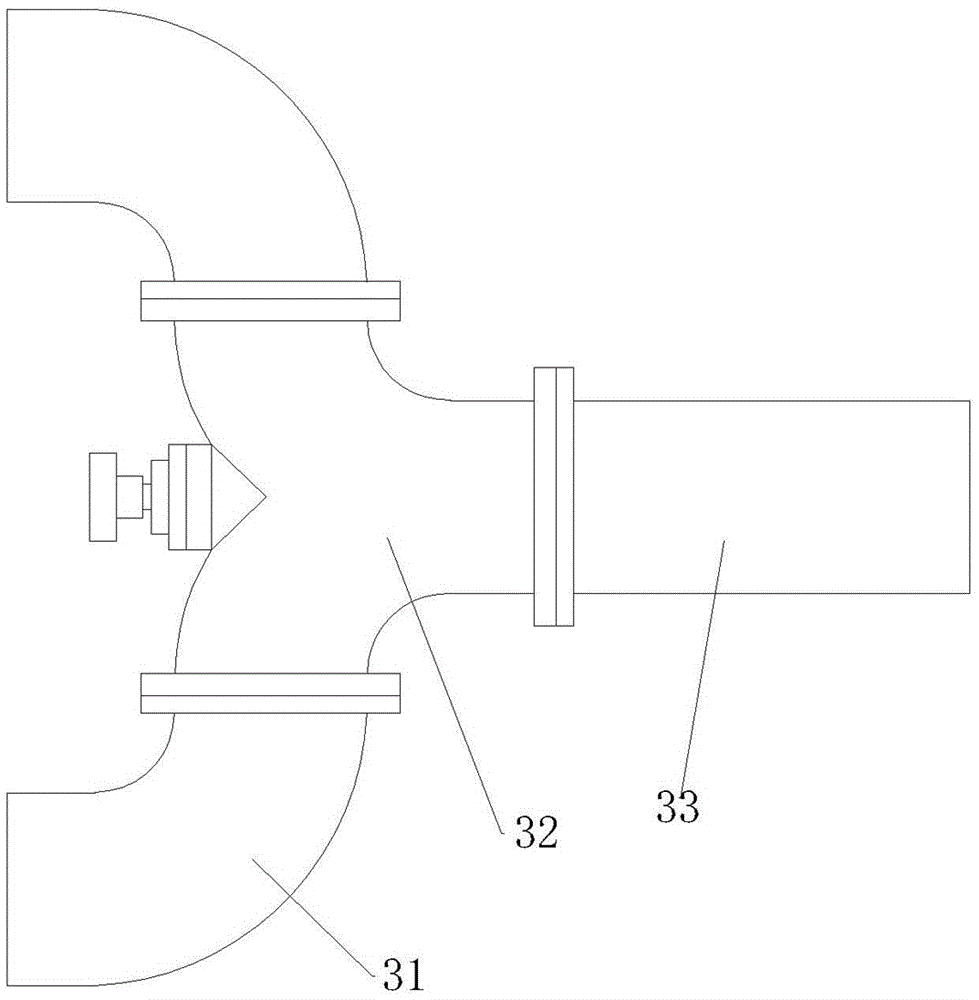

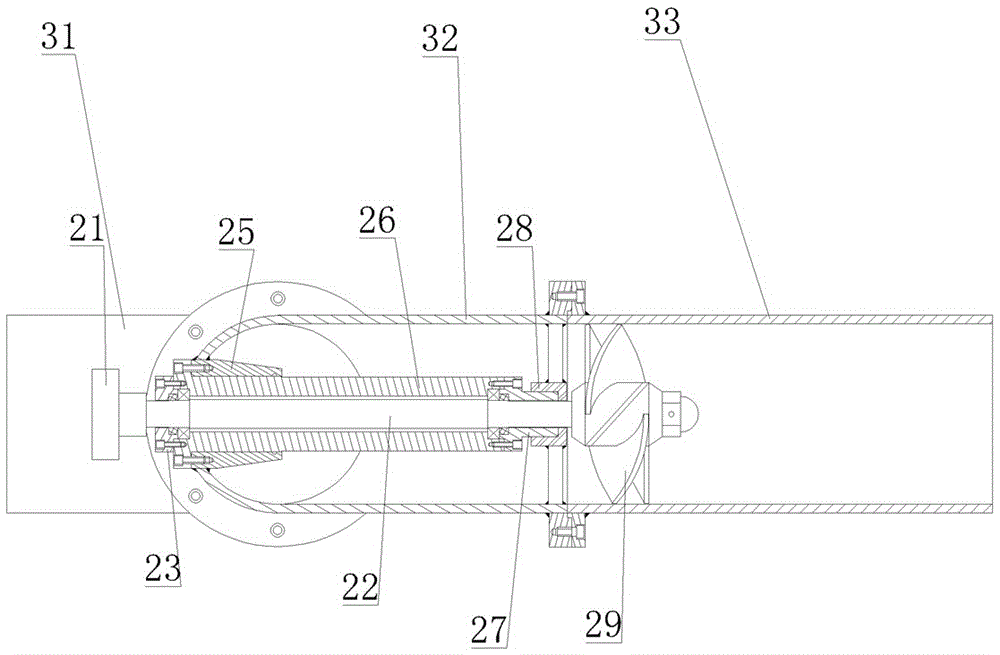

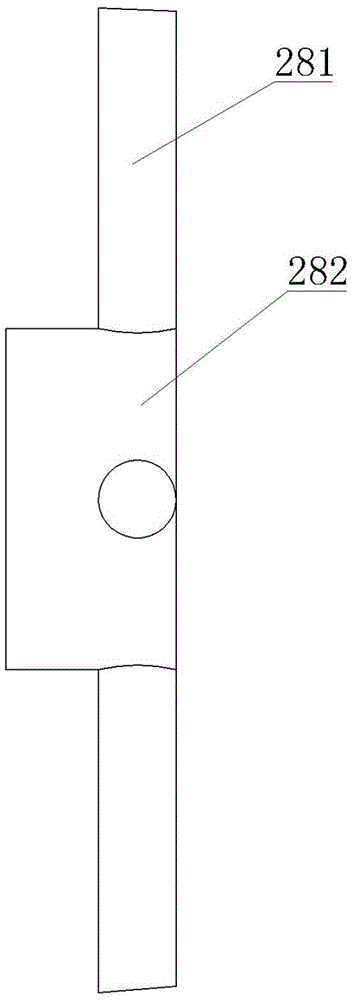

[0017] Referring to the accompanying drawings, the water jet propeller includes a main shaft 22, a helical impeller 29, a water suction pipe 31, a water spray pipe 33, a shell-shaped propeller main body 32, a bearing block 26, a shaft coupling 21, a front bearing gland 23, a front Support 25, rear bearing gland 27, rear support 28. The main body 32 of the propeller is a three-way pipe of equal diameter, that is, the diameters of the two water inlet pipes and one water outlet pipe are the same, and the two water inlet pipes are symmetrically distributed in an arc shape, and the diameter is the same as that of the water suction pipe 31. , the diameter of the outlet pipe is the same as that of the water spray pipe 33, and the two are also connected by flanges. The front end and the rear end in the main body of the propeller are respectively fixedly connected with a front bracket 25 and a rear bracket 28; the bearing seat is a straight pipe with a flange on the front end , the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com