Magnetic suspension conveyor belt

A magnetic levitation and conveyor belt technology, applied in the field of conveyor belts, can solve the problems of heavy maintenance workload, short service period, friction loss, etc., and achieve the effect of small footprint, long service period and small friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

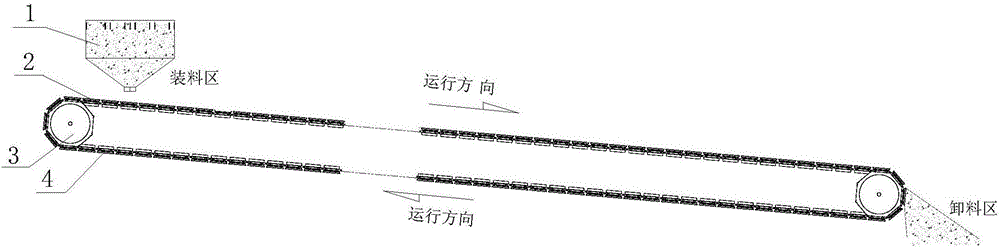

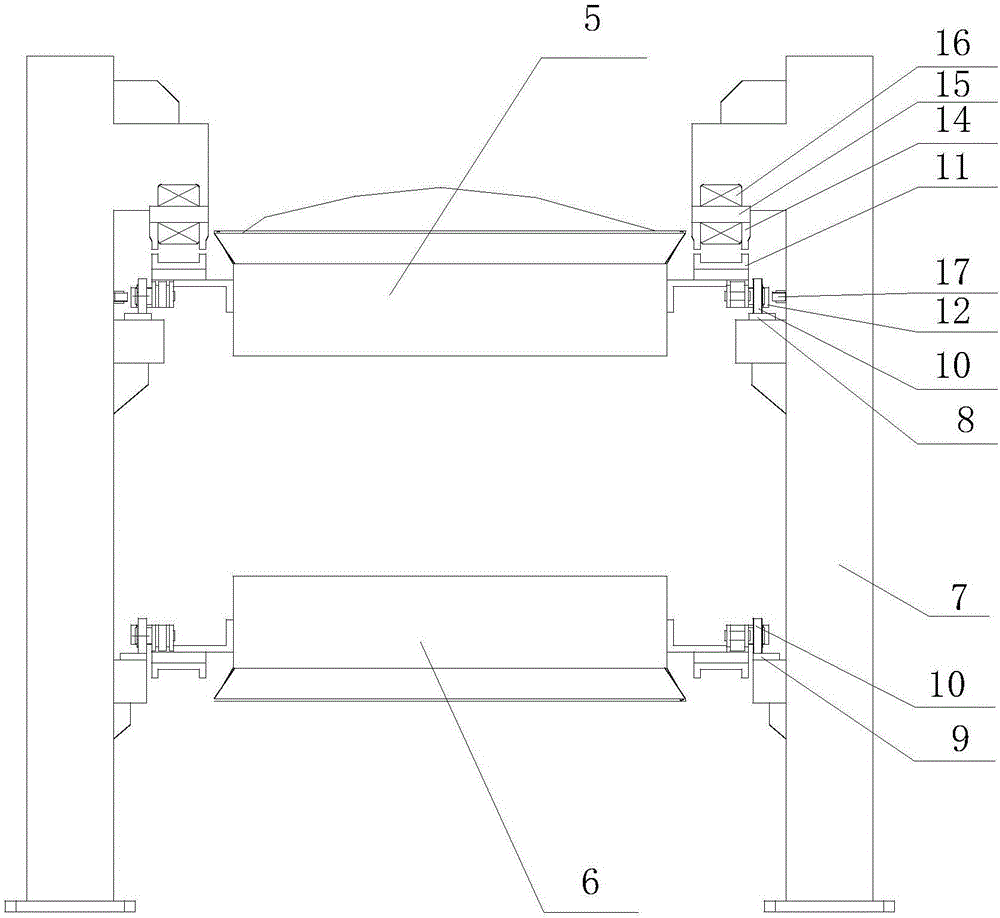

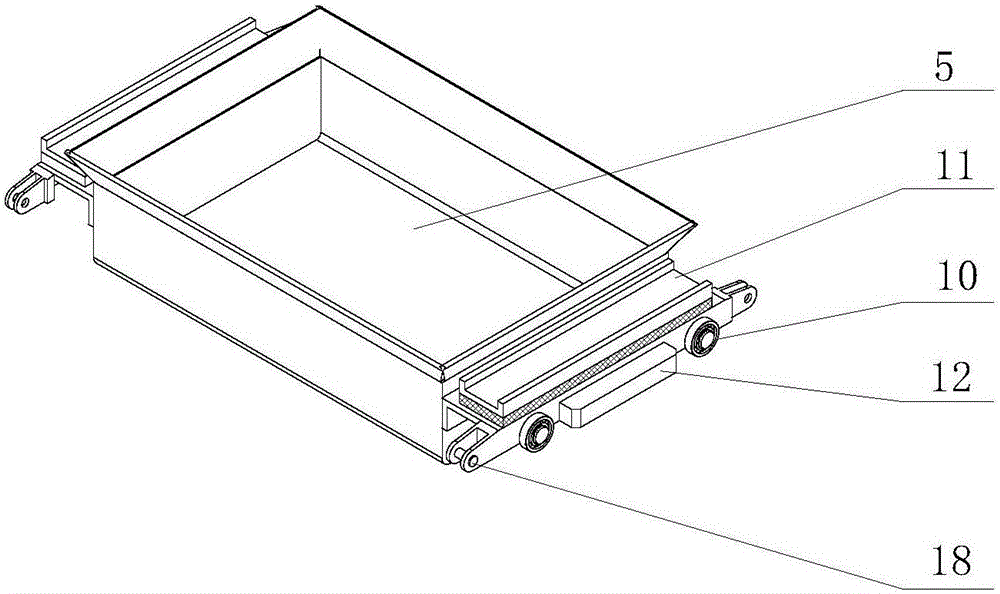

[0048] Referring to 1, the present invention provides a magnetic levitation conveyor belt, comprising a track, the track is a circular track vertically arranged up and down, and the circular track includes an upper track 2, a lower track 3 and two bends connecting the two ends of the upper track 2 and the lower track 3. Road, the upper track 2 and the lower track 3 are parallel, and the inside of the curve is provided with a curve runner 4. The whole annular track is arranged obliquely to form a certain slope. Below the silo 1 is the loading area. The loading area is arranged upstream of the upper track 2 , and the unloading area is set downstream of the upper track 3 . When the conveyor belt works like this, the hoppers running on the upper track after the loading area are all fully loaded, and the hoppers running on the lower track after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com