Automatic feeding machine and feeding method

A technology for automatic feeding and sheet material, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing labor costs, reducing production efficiency, and harsh operating environment, and reducing labor costs, improving production efficiency, and manufacturing. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

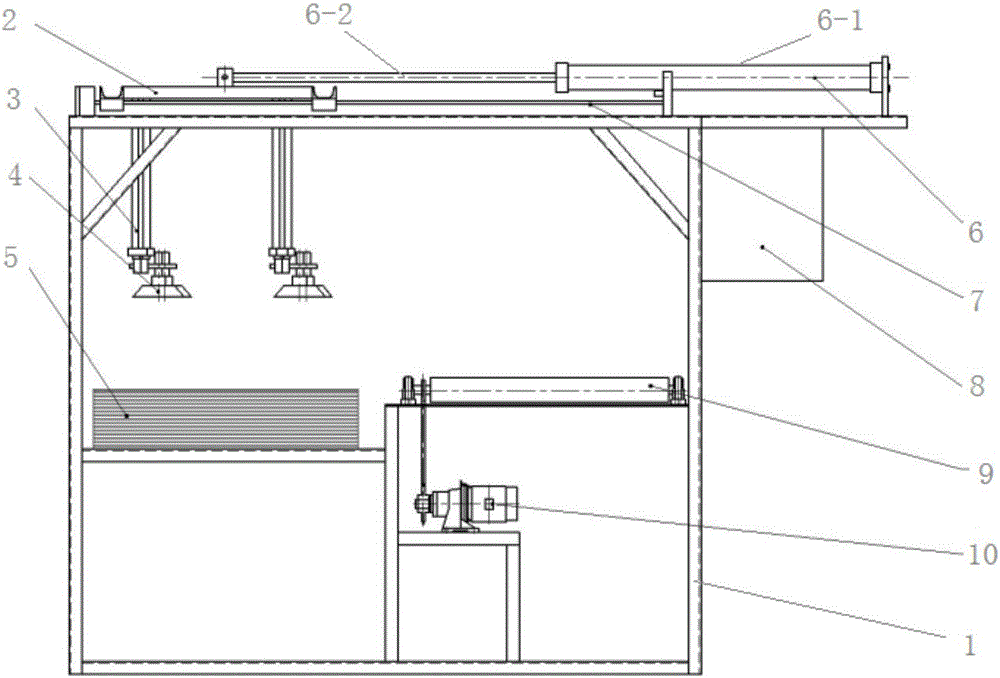

[0013] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: it includes a box support 1, a mobile frame 2, a feeding cylinder 3, a suction cup 4, a sheet material 5, a material transfer cylinder 6, a cylinder barrel 6-1, and a piston rod 6-2 , linear guide rail 7, electrical control cabinet 8, transmission roller 9 and main motor 10, sheet material 5 is placed on the upper end of one side of support 1, transmission roller 9 and main motor 10 are installed on the upper end of the other side of support 1, and the lower end of transmission roller 9 is set There is a main motor 10, the transmission roller 9 and the main motor 10 are connected through a belt transmission, the top of the support 1 is provided with a transfer cylinder 6 and a linear guide rail 7, and the upper end of the linear guide rail 7 is equipped with a moving frame 2, and the cylinder 6-1 is connected with the support 1. The top of the side is fixedly connected, the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com