Chain-delivered winding shaft for winder

A technology of rewinding shaft and rewinding machine, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of impact, noise, vibration and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

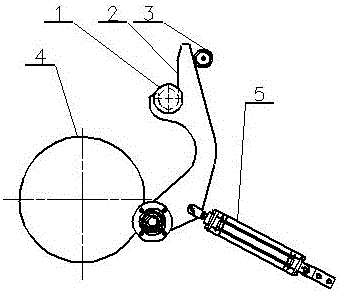

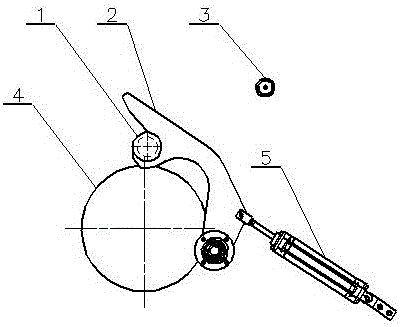

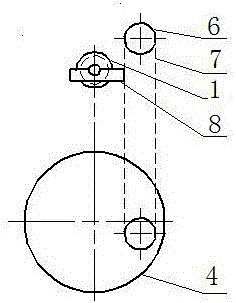

[0012] Such as Figure 1 to Figure 4 As shown, the winding machine chain delivers the winding shaft, including the winding shaft 1, the crank arm 2, the limit block 3, the friction roller 4, the cylinder 5, the sprocket 6, the chain 7 and the support plate 8, and the winding shaft 1 is arranged on the crank arm 2, the curved arm 2 is connected with the cylinder 5, the friction roller 4 is connected with the curved arm 2, the sprocket 6 is connected with the chain 7, and the support plate 8 is fixed on the chain 7. The present invention uses the chain to move up and down in a straight line to deliver, and the take-up shaft falls To the initial winding position, the chain is driven by a motor to move, and the support plate supports the winding shaft to move up and down with the chain. The designed moving speed of the winding shaft is low and will not cause impact, which overcomes the traditional winding shaft rotation and delivery due to the weight. The impact of the reel on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com