Extra-high voltage series compensation platform equipment lifting portable repair device

An ultra-high voltage, portable technology, applied in transportation and packaging, load suspension components, cranes, etc., can solve the problems of large capacitors, difficulty in ensuring safety, and visual blind spots for high-altitude operations, so as to increase the operating radius and increase effective operations Length, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

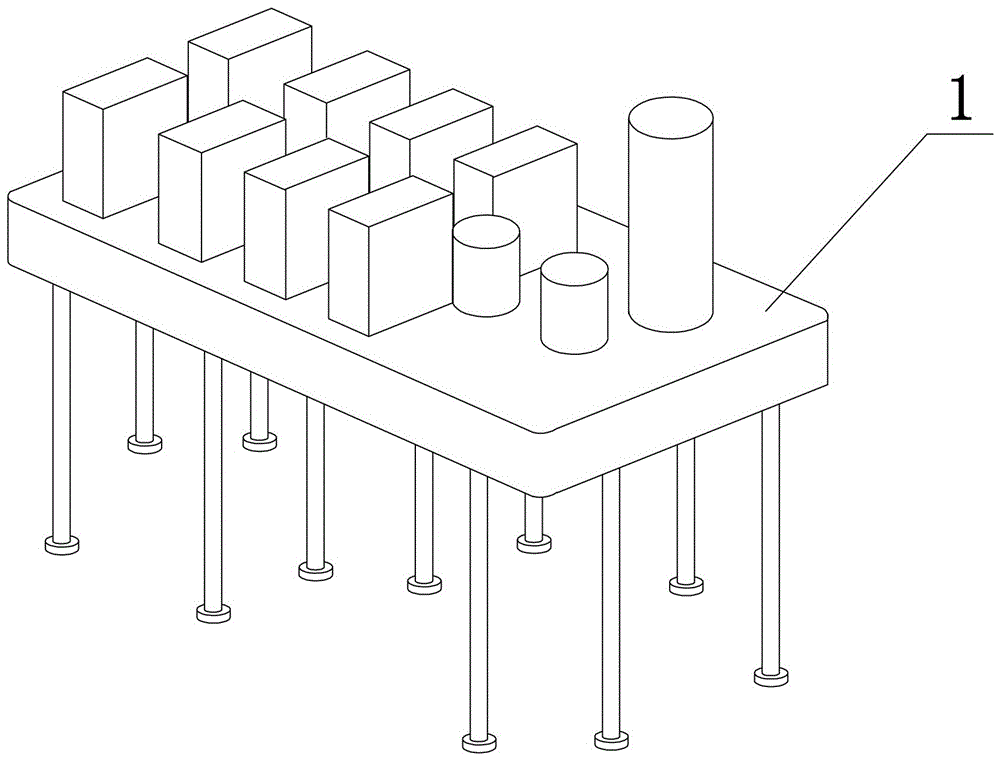

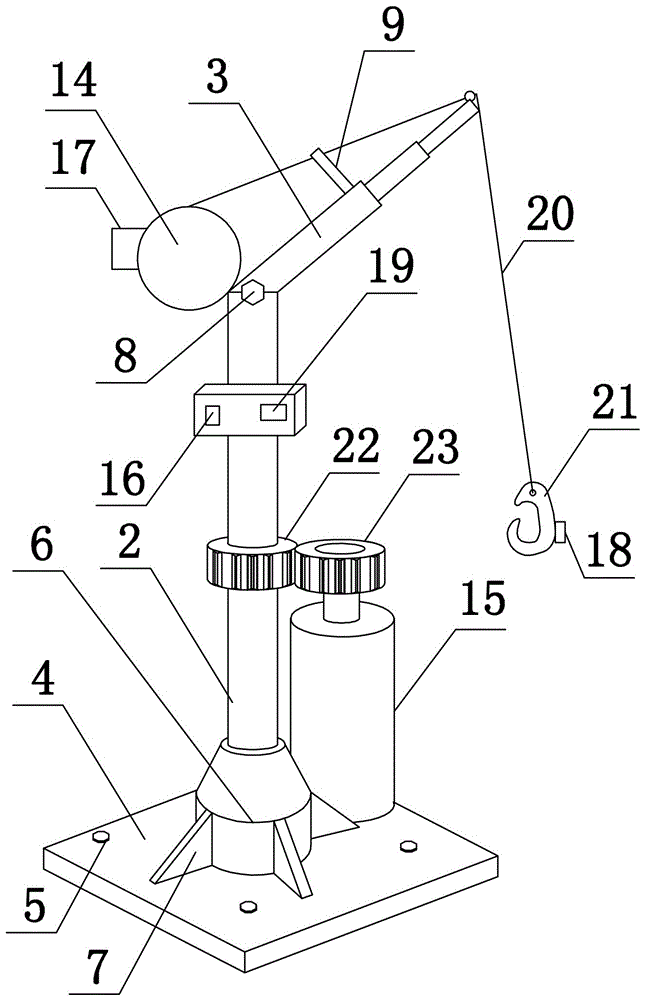

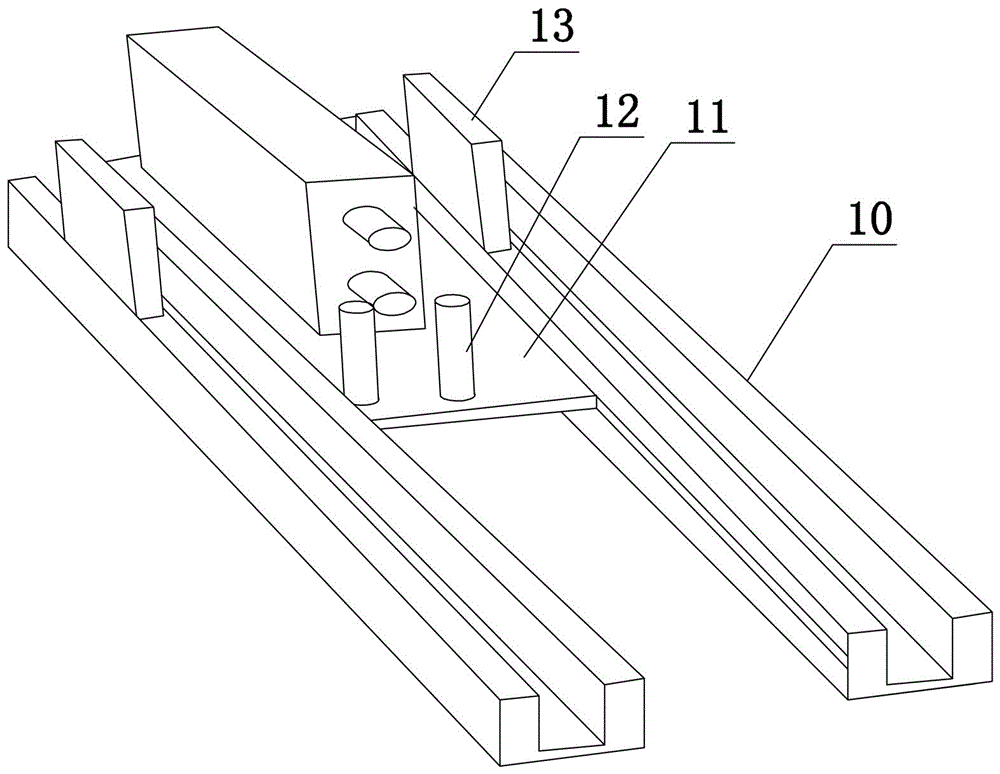

[0038] like figure 2 As shown, the present invention includes a hoisting mechanism, a transfer mechanism and a control system, wherein,

[0039] The hoisting mechanism includes a fixed base, a support rod 2 and an upper arm 3, and the fixed base includes a fixed plate 4, a fastener 5 for fixing the fixed plate 4 and the serial compensation platform 1, and an adapter for connecting the support rod 2 6. Fasteners 5 use bolts, adapters 6 are bearings welded to the upper end surface of fixed plate 4, ribs 7 are welded between adapters 6 and fixed plate 4, and the lower end of support rod 2 and adapter 6 The inner ring (not shown in the figure) is fixedly connected, the upper end of the support rod 2 is hinged with one end of the upper support arm 3, and a fastening bolt 8 is set at the connection between the support rod 2 and the upper support arm 3, and the upper support arm 3 is hydraulically telescopic Cylinder and welding limit ring 9 on its upper end face;

[0040] like ...

Embodiment 2

[0043] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 As shown, the free end of the traction rope 20 is also provided with a clamping device. The clamping device includes two groove-shaped clips 28 arranged symmetrically. One end of the groove-shaped clip 28 is provided with a semi-ring guard plate 29. A limiting protrusion 30 is arranged in the groove at the other end of the body 28, and the two groove-shaped clamping bodies 28 are fixed by bolts.

Embodiment 3

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Image 6 As shown, when the series compensation platform 1 is a grid structure, the first through hole (not shown in the figure) is set on the fixed plate 4, the fixing bolt 31 is set through the first through hole, the fastener 5 is an M-shaped plate, and the M The shape plate is installed between the fixed plate 4 and the series compensation platform 1 and is provided with a second through hole (not shown in the figure). After the fixing bolt 31 passes through the first through hole and the second through hole, a nut 32 is installed. The nut 32 is located at the The lower end face of platform 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com