Ultrathin glass conveying device

A conveying device, ultra-thin glass technology, applied in glass transportation equipment, glass production, glass manufacturing equipment, etc., can solve the problems of difficulty in accurately measuring the conveying speed of glass plates, difficult to measure by photoelectric sensors, difficult in conveying speed, etc., to reduce the quality defects, improved apparent quality, improved effects of environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

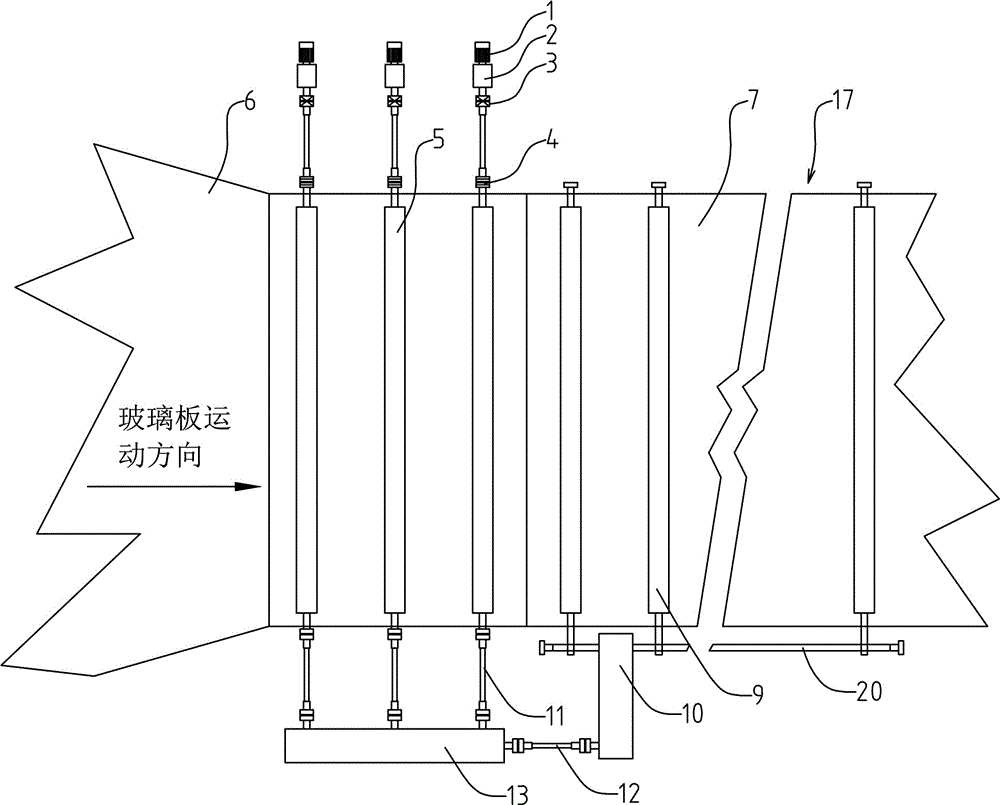

[0028] Such as Figure 1~6 Among them, an ultra-thin glass conveying device includes a plurality of transition rollers 5 located between the tin bath 6 and the annealing furnace 17, the transition rollers 5 are supported on the frame by bearings, and a cooling device is also provided to reduce the working temperature of the bearings. Temperature, one end of a plurality of transition rollers 5 is connected to a driving device through a first transmission mechanism, and the other end of a plurality of transition rollers 5 is connected to a driving device through a second transmission mechanism respectively;

[0029] In the first transmission mechanism described above, the driving device is connected to the deceleration device 10, the deceleration device 10 is fixedly connected to one end of the connecting shaft 12, and the other end of the connecting shaft 12 is connected to a plurality of overrunning clutches 13, and the plurality of overrunning clutches 13 are respectively conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com