Method for optimizing filling material ratio

A filling and cementing filling technology, which is applied in the direction of ratio control, instrumentation, non-electric variable control, etc., can solve the problems that affect the popularization and practicality of the model, and single consideration factors, so as to achieve the goal of reducing filling cost, high prediction effect, and reducing the number of experiments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for optimizing the ratio of fillers, comprising the steps of:

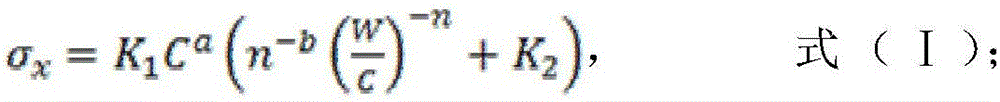

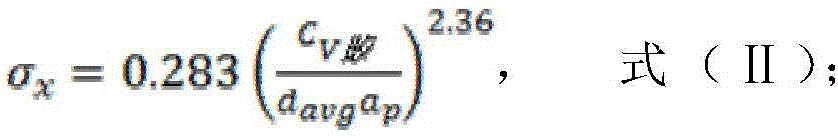

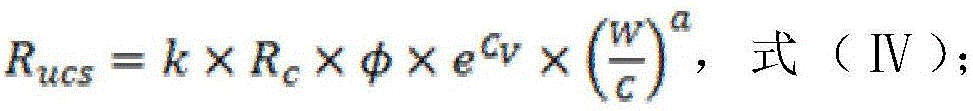

[0073] In step (1), the strength model of the cemented filling body includes formula (IV) and formula (V), as follows:

[0074]

[0075] Satisfy the slurry saturation condition at the same time:

[0076]

[0077] C / ρ 水泥 +M 骨 / ρ 骨 +W / 1000=1, formula (Ⅵ);

[0078] In formula (IV), formula (V) and formula (VI),

[0079] R ucs ——the uniaxial compressive strength of the cemented filling body, MPa;

[0080] φ——Aggregate packing density;

[0081] φ′——solid material packing density;

[0082] C V ——aggregate volume concentration per unit volume of slurry;

[0083] W / C - slurry water-cement mass ratio;

[0084] W is water volume, unit kg / m 3 ;

[0085] C is the amount of cement added, unit kg / m 3 ;

[0086] m 骨 Amount of aggregate added, unit kg / m 3 ;

[0087] ρ 骨 is aggregate density, unit kg / m 3 ;

[0088] ρ 水泥 is cement density, unit kg / m 3 ;

[0089] R c - cement grade, MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Amount of water | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com