Polymer-modified repair mortar

A technology for repairing mortar and polymer, which is applied in the field of building materials, can solve the problems that the repair effect of polymer modified repair mortar cannot meet the repair requirements of engineering design, repair failure and other problems, and achieve easy on-site maintenance, improved workability, and reduced The effect of drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

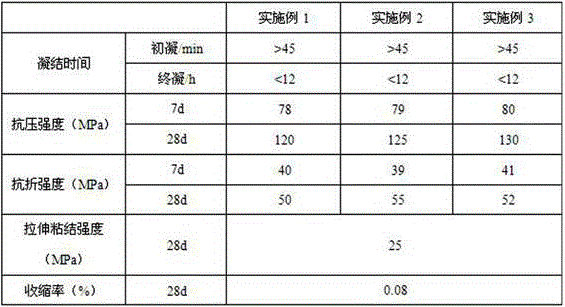

Examples

Embodiment 1

[0024] Embodiment 1—polymer modified repair mortar

[0025] It is made from the following raw materials:

[0026] 700kg of sand, 180kg of cement, 40kg of fly ash, 80kg of mineral powder, 5kg of latex powder and 0.3kg of cellulose ether;

[0027] Wherein, described sand refers to the sand that has following particle gradation structure:

[0028] 9.5mm sieve hole: 0%;

[0029] 4.75mm sieve hole: 0%;

[0030] 2.36mm sieve hole: 5%;

[0031] 1.18mm sieve hole: 10%;

[0032] 600μm sieve residue: 71%;

[0033] 300μm sieve residue: 85%;

[0034] 150μm sieve residue: 80%;

[0035] Described fly ash refers to the fly ash that 0.045mm sieve hole sieves is less than 25%;

[0036] The mineral powder refers to a mineral powder with a specific surface area ≥ 400㎡ / kg and a 28-day activity index ≥ 98%.

Embodiment 2

[0037] Example 2—polymer modified repair mortar

[0038] It is made from the following raw materials:

[0039] 790kg of sand, 120kg of cement, 80kg of fly ash, 50kg of mineral powder, 2kg of latex powder and 1kg of cellulose ether;

[0040] Wherein, described sand refers to the sand that has following particle gradation structure:

[0041] 9.5mm sieve hole: 0%;

[0042] 4.75mm sieve hole: 0%;

[0043] 2.36mm sieve hole: 5%;

[0044] 1.18mm sieve hole: 10%;

[0045] 600μm sieve residue: 71%;

[0046] 300μm sieve residue: 85%;

[0047] 150μm sieve residue: 80%;

[0048] Described fly ash refers to the fly ash that 0.045mm sieve hole sieves is less than 25%;

[0049] The mineral powder refers to a mineral powder with a specific surface area ≥ 400㎡ / kg and a 28-day activity index ≥ 98%.

Embodiment 3

[0050] Embodiment 3—polymer modified repair mortar

[0051] It is made from the following raw materials:

[0052] 730kg of sand, 150kg of cement, 60kg of fly ash, 60kg of mineral powder, 1kg of latex powder and 0.1kg of cellulose ether;

[0053] Wherein, described sand refers to the sand that has following particle gradation structure:

[0054] 9.5mm sieve hole: 0%;

[0055] 4.75mm sieve hole: 10%;

[0056] 2.36mm sieve hole: 20%;

[0057] 1.18mm sieve hole: 50%;

[0058] 600μm sieve residue: 51%;

[0059] 300μm sieve: 70%;

[0060] 150μm sieve: 100%;

[0061] Described fly ash refers to the fly ash that 0.045mm sieve hole sieves is less than 25%;

[0062] The mineral powder refers to a mineral powder with a specific surface area ≥ 400㎡ / kg and a 28-day activity index ≥ 98%.

[0063] The preparation method of the polymer-modified repair mortar described in the above-mentioned embodiments is as follows: take the above-mentioned raw materials in proportion, add them to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com