Novel road surface permeable concrete product and preparation method of novel road surface permeable concrete product

A technology of permeable concrete and products, which is applied in the field of concrete, can solve the problems of outstanding engineering quality warranty, large product performance differences, cumbersome construction technology, etc., achieve significant economic and environmental benefits, reduce the number of mining, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

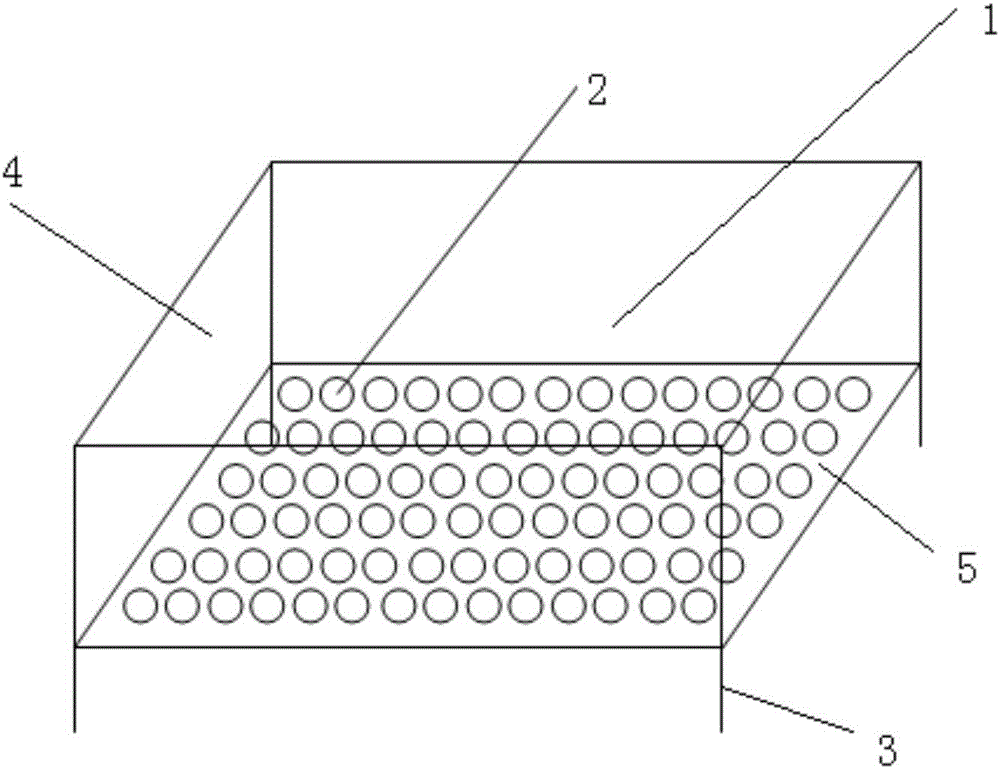

Image

Examples

Embodiment 1

[0042] The embodiment of the present invention provides a kind of preparation method of novel pavement permeable concrete product, and preparation method comprises the following steps:

[0043] 1) Weigh 700kg of ordinary aggregate, 300kg of waste rubber aggregate, 320kg of Portland cement, 65kg of fly ash, 65kg of mineral powder, 12kg of composite admixture, and 115kg of water, and add them to the mixer, and stir evenly at high speed to obtain admixture;

[0044] Among them, the composite aggregate is composed of ordinary aggregate and waste rubber aggregate, and the ordinary aggregate and waste rubber aggregate are mixed at a volume ratio of 7:3 to form a composite aggregate. Ordinary aggregate is a single-grained aggregate with a particle size of 5mm-10mm processed from dense and hard rock; rubber aggregate is a waste tire rubber particle with a particle size of 3-5mm. Ordinary aggregates are aggregates in a saturated surface-dry state, and waste tire rubber aggregates are ...

Embodiment 2

[0051] The embodiment of the present invention provides a kind of preparation method of novel pavement permeable concrete product, and preparation method comprises the following steps:

[0052] 1) Weigh 600kg of ordinary aggregate, 400kg of waste rubber aggregate, 300kg of Portland cement, 60kg of fly ash, 60kg of mineral powder, 11.5kg of composite admixture, and 120kg of water, and add them to the mixer, and stir evenly at high speed. get the mixture;

[0053] Among them, the composite aggregate is composed of ordinary aggregate and waste rubber aggregate, and the ordinary aggregate and waste rubber aggregate are mixed at a volume ratio of 6:4 to form a composite aggregate. Ordinary aggregate is a single-grained aggregate with a particle size of 5mm-10mm processed from dense and hard rock; rubber aggregate is a waste tire rubber particle with a particle size of 3-5mm. Ordinary aggregates are aggregates in a saturated surface-dry state, and waste tire rubber aggregates are p...

Embodiment 3

[0060] The embodiment of the present invention provides a kind of preparation method of novel pavement permeable concrete product, and preparation method comprises the following steps:

[0061] 1) Weigh 500kg of ordinary aggregate, 500kg of waste rubber aggregate, 300kg of Portland cement, 45kg of fly ash, 75kg of mineral powder, 8.5kg of composite admixture, and 130kg of water, and add them to the mixer, and stir at a high speed evenly. get the mixture;

[0062] Among them, the composite aggregate is composed of ordinary aggregate and waste rubber aggregate, and the ordinary aggregate and waste rubber aggregate are mixed at a volume ratio of 5:5 to form a composite aggregate. Ordinary aggregate is a single-grained aggregate with a particle size of 5mm-10mm processed from dense and hard rock; rubber aggregate is a waste tire rubber particle with a particle size of 3-5mm. Ordinary aggregates are aggregates in a saturated surface-dry state, and waste tire rubber aggregates are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com