Method for preparing hfc-sic modified c/c composite material by high temperature-dipping cracking process

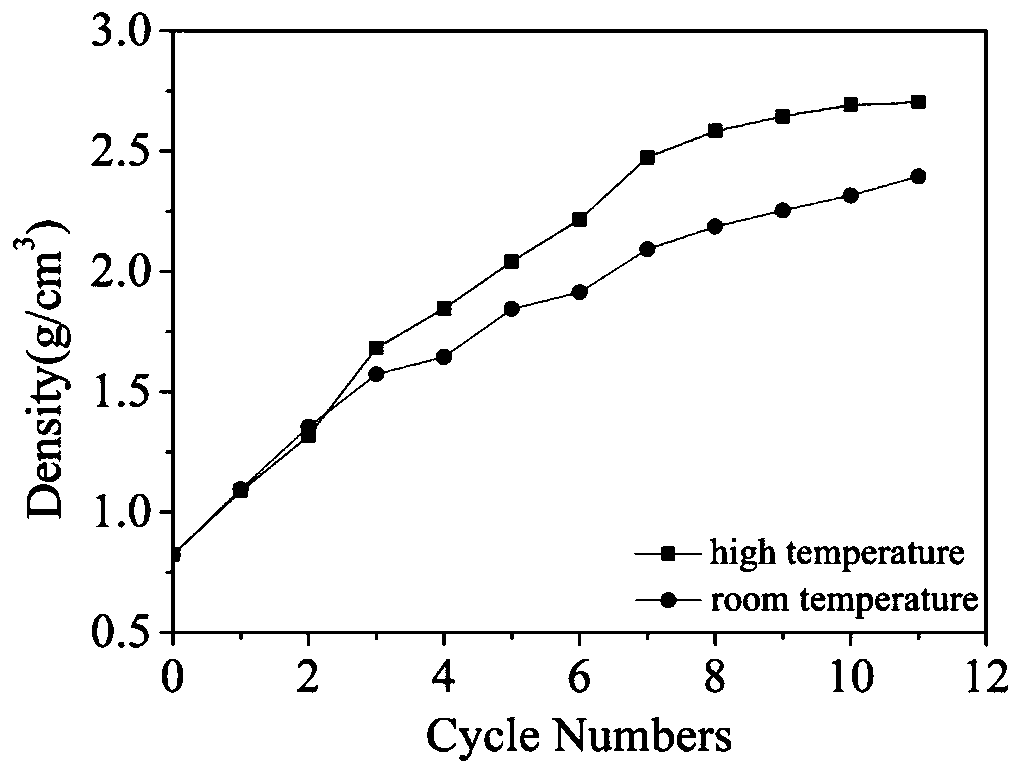

A composite material, dipping and cracking technology, applied in the field of C/C composite material preparation, can solve the problems affecting the preparation efficiency of materials, uneven distribution of ceramics, crusting on the surface of materials, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

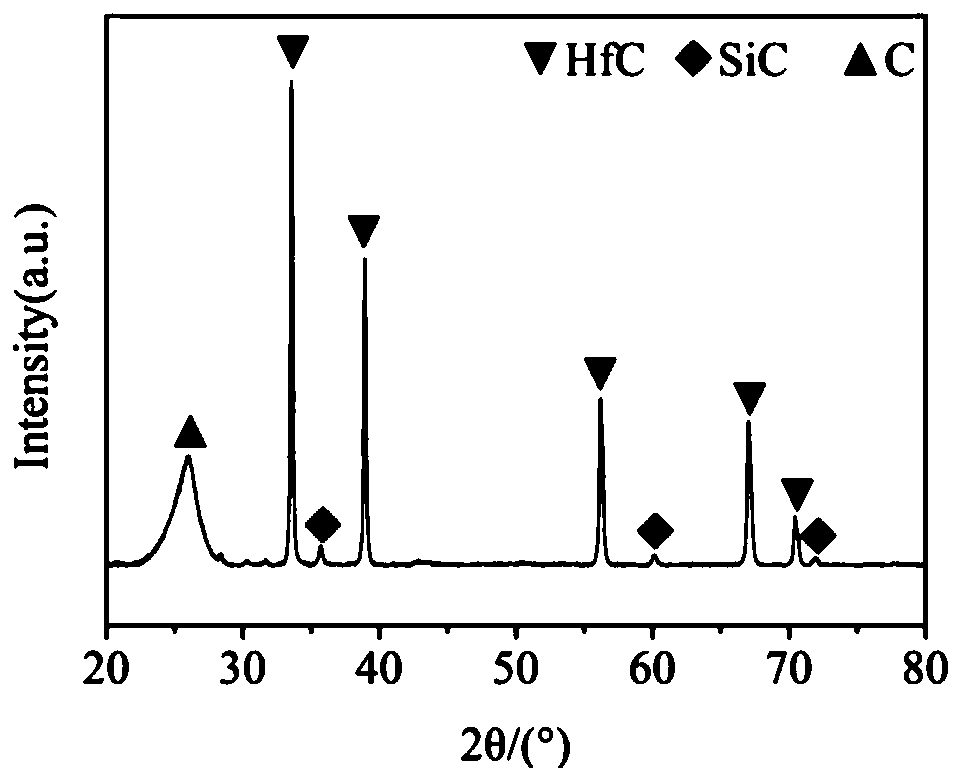

[0032] This example is a preparation method of HfC-SiC modified C / C composite material.

[0033]Step 1: carbon felt cleaning: the density is 0.45g / cm 3 Put the carbon felt in absolute ethanol for ultrasonic cleaning for 15 minutes, and then dry it in an oven with a drying temperature of 70°C for later use;

[0034] Step 2: Prepare porous low-density C / C preform: place the cleaned carbon felt in an isothermal chemical vapor deposition furnace, use natural gas as the reaction gas source, and the gas flow rate is 0.5m 3 / h, the deposition temperature is 950°C, and the deposition time is 50h. After the end, it is cooled with the furnace to obtain a porous low-density C / C preform;

[0035] Step 3: Preform cleaning: The porous low-density C / C preform obtained after deposition was ultrasonically cleaned in absolute ethanol for 15 minutes, and then dried in an oven at a drying temperature of 70°C for later use;

[0036] Step 4: Introduction of HfC-SiC ceramic phase: the specific pro...

Embodiment 2

[0042] Step 1: carbon felt cleaning: the density is 0.47g / cm 3 Put the carbon felt in absolute ethanol for ultrasonic cleaning for 20 minutes, and then dry it in an oven with a drying temperature of 75°C for later use;

[0043] Step 2: Prepare porous low-density C / C preform: place the cleaned carbon felt in an isothermal chemical vapor deposition furnace, use natural gas as the reaction gas source, and the gas flow rate is 0.6m 3 / h,N 2 As a carrier gas, the deposition temperature is 1050°C, and the deposition time is 45 hours. After the end, it is cooled with the furnace to obtain a porous low-density C / C preform;

[0044] Step 3: Cleaning of the prefabricated body: The porous low-density C / C prefabricated body prepared after deposition was ultrasonically cleaned in absolute ethanol for 20 minutes, and then dried in an oven at a drying temperature of 75°C for later use;

[0045] Step 4: Introduction of HfC-SiC ceramic phase: the specific process is:

[0046] 1) Preparation...

Embodiment 3

[0051] Step 1: carbon felt cleaning: the density is 0.46g / cm 3 Put the carbon felt in absolute ethanol for ultrasonic cleaning for 10 minutes, and then dry it in an oven with a drying temperature of 65°C for later use;

[0052] Step 2: Prepare porous low-density C / C preform: place the cleaned carbon felt in an isothermal chemical vapor deposition furnace, use natural gas as the reaction gas source, and the gas flow rate is 0.7m 3 / h, the deposition temperature is 1100°C, and the deposition time is 40h. After the end, it is cooled with the furnace to obtain a porous low-density C / C preform;

[0053] Step 3: Cleaning of the prefabricated body: The porous low-density C / C prefabricated body prepared after deposition was ultrasonically cleaned in absolute ethanol for 10 minutes, and then dried in an oven at a drying temperature of 65°C for later use;

[0054] Step 4: Introduction of HfC-SiC ceramic phase: the specific process is:

[0055] 1) Preparation of precursor mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com