A kind of low abrasion conductive PBT/PET composite material and preparation method thereof

A composite material and low-abrasion technology, which is applied in the field of low-abrasion carbon nanotube conductive PBT/PET composite material and its preparation, can solve the problem that the surface treatment and dispersion of carbon nanotubes are not involved, the specific surface area of carbon nanotubes is large, and the composition is not easy. Uniform dispersion and other problems, to achieve the effect of good electrical conductivity, good mechanical properties, and small amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

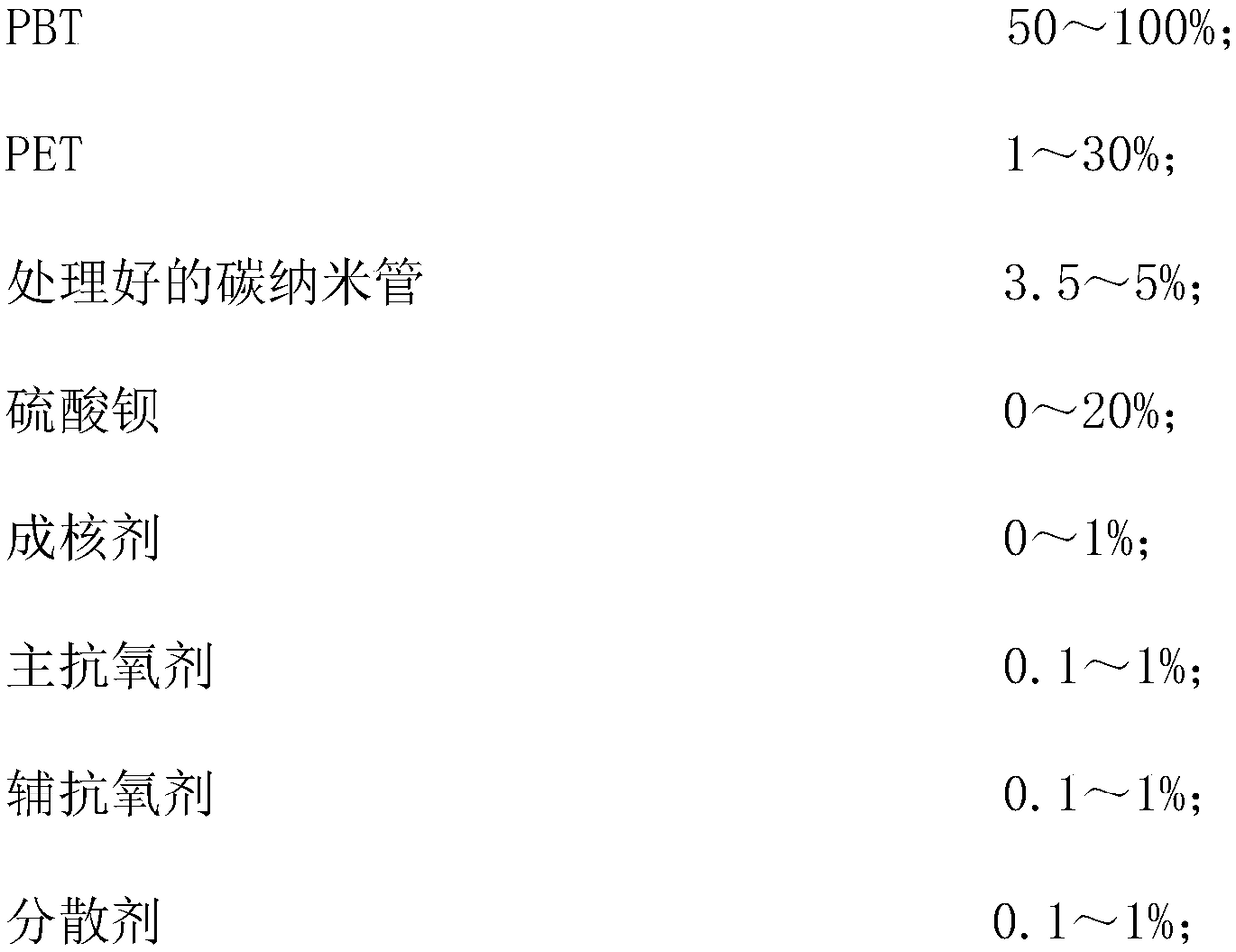

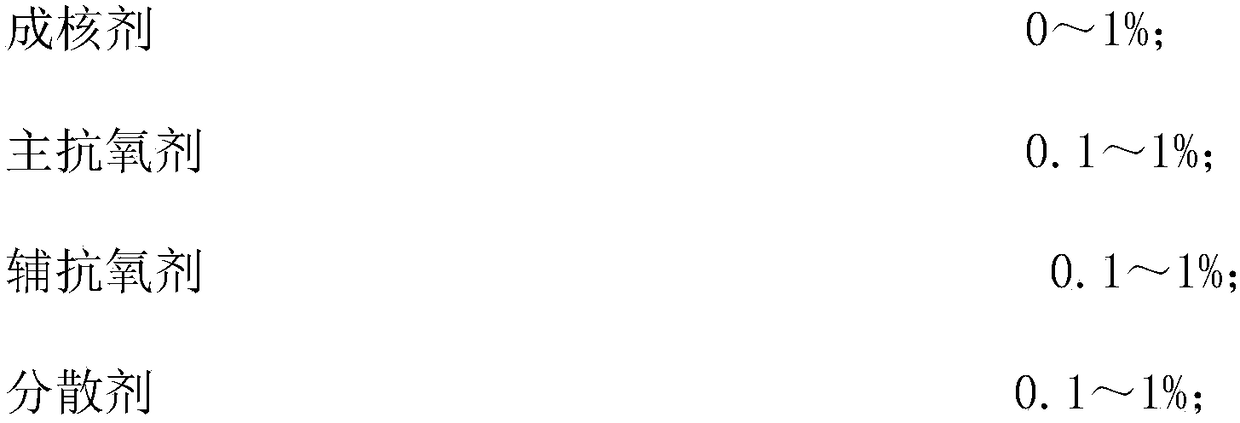

Method used

Image

Examples

Embodiment 1

[0024] (1) According to PBT 84.6%, PET 5%, treated carbon nanotubes 3.5%, barium sulfate 6%, nucleating agent 0.2%, antioxidant 1010 0.2%, antioxidant 168 0.2% and dispersant 0.3% After accurate weighing, pre-dry at 85-90°C;

[0025] (2) Add the above-mentioned dried materials into a high-speed mixer for dry mixing for 1 to 4 minutes, then put the mixed materials into a twin-screw extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain the finished product . The barrel temperature of the extruder is 200-230° C., and the screw speed is 300 rpm. The preparation steps of the second embodiment are the same as the first embodiment, and the formula is: 90.6% of PBT, 5% of PET, 3.5% of the treated carbon nanotubes, 0.2% of the nucleating agent, 0.2% of the antioxidant 1010, and 0.2% of the antioxidant 168 and dispersant 0.3%.

Embodiment 3

[0027] The preparation steps are the same as in Example 1, and the formula is: PBT 84.1%, PET 5%, treated carbon nanotubes 4%, barium sulfate 6%, nucleating agent 0.2%, antioxidant 1010 0.2%, antioxidant 168 0.2% and dispersant 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com