A kind of fiberglass radome profile and preparation method thereof

A technology of glass fiber reinforced plastics and cover profiles, applied in the field of composite materials, can solve problems such as troubles, mold blocking, and interruption of production, and achieve the effects of efficient curing, guaranteed mechanical properties, and prolonged gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

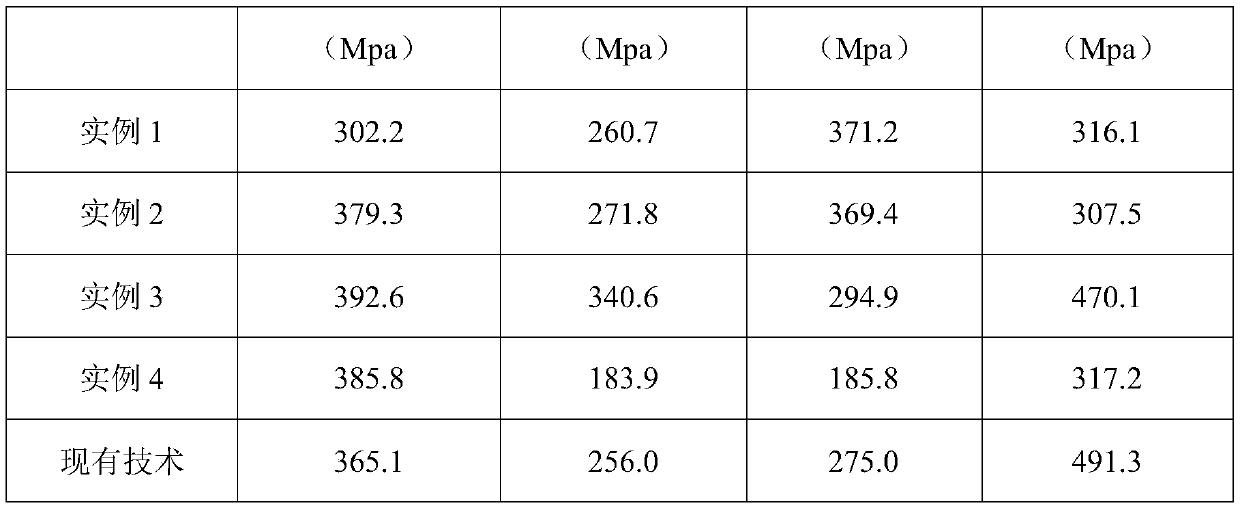

[0021] This embodiment relates to a FRP radome profile, wherein the glass fiber mass fraction accounts for 65%, and the resin compound mass fraction accounts for 35%; the parts by weight of each component of the resin compound are: unsaturated polyester: 100 parts Aluminum hydroxide: 15 parts; Color paste: 2 parts; Phosphate release agent: 0.8 part; Amine antioxidant: 0.1 part; 3 parts of curing system, the curing system includes accelerator and initiator; The initiators include BPO, AW and TBPB; wherein the accelerator in the curing system: BPO:AW:TBPB=0.5:0.4:0.3:0.3.

[0022] The properties of the resin mixture are shown in Table 1.

[0023] The present invention also relates to a method for preparing the FRP radome profile, which is characterized in that it comprises the following steps:

[0024] The first step: at room temperature, add 100 parts of resin, 15 parts of filler, 3 parts of color paste, 1 part of release agent and 0.2 part of antioxidant into the material tan...

Embodiment 2

[0031] This embodiment relates to a FRP radome profile. Except for the different component ratios in the curing system, other components and preparation methods are the same as in Example 1; specifically, the mass fraction of glass fiber accounts for 65%, and the mass fraction of resin mixture accounts for 35%. The parts by weight of each component of the resin mixture are: unsaturated polyester: 100 parts; aluminum hydroxide: 15 parts; color paste: 2 parts; phosphate ester mold release agent: 0.8 parts; amine antioxidant : 0.1 part; 3 parts of the curing system, the accelerator in the curing system: BPO:AW:TBPB=0.5:0.3:0.2:0.1.

[0032] The properties of the resin mixture are shown in Table 1.

Embodiment 3

[0034] This embodiment relates to a FRP radome profile. Except for the different component ratios in the curing system, other components and preparation methods are the same as in Example 1; specifically, the mass fraction of glass fiber accounts for 65%, and the mass fraction of resin mixture accounts for 35%. The parts by weight of each component of the resin mixture are: unsaturated polyester: 100 parts; aluminum hydroxide: 15 parts; color paste: 2 parts; phosphate ester mold release agent: 0.8 parts; amine antioxidant : 0.1 part; 3 parts of curing system, accelerator in the curing system: BPO:AW:TBPB=0.5:0.2:0.1:0.3. The properties of the resin mixture are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com