Wine distillation device

A technology of wine steaming equipment and fermented grains, applied in the preparation of alcoholic beverages, etc., can solve the problems of mixing and affecting the quality of wine, and achieve the effect of lowering the temperature of wine, reducing impurities with high boiling points, and enhancing extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

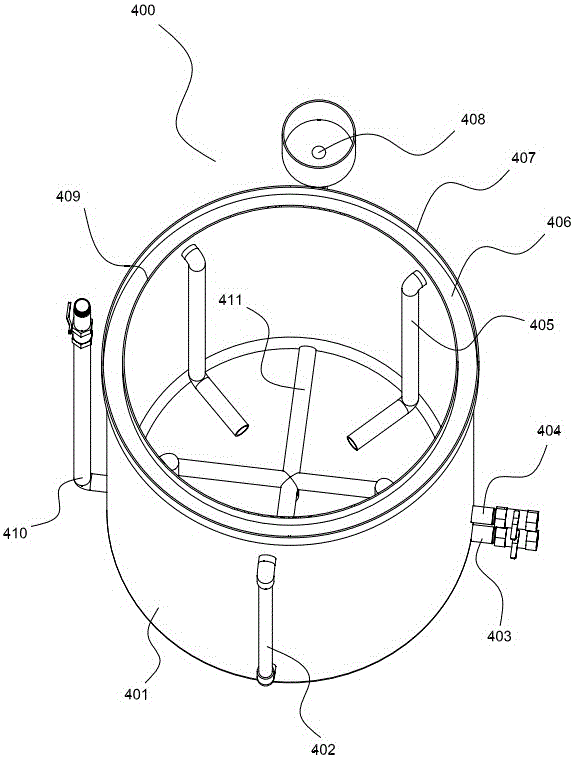

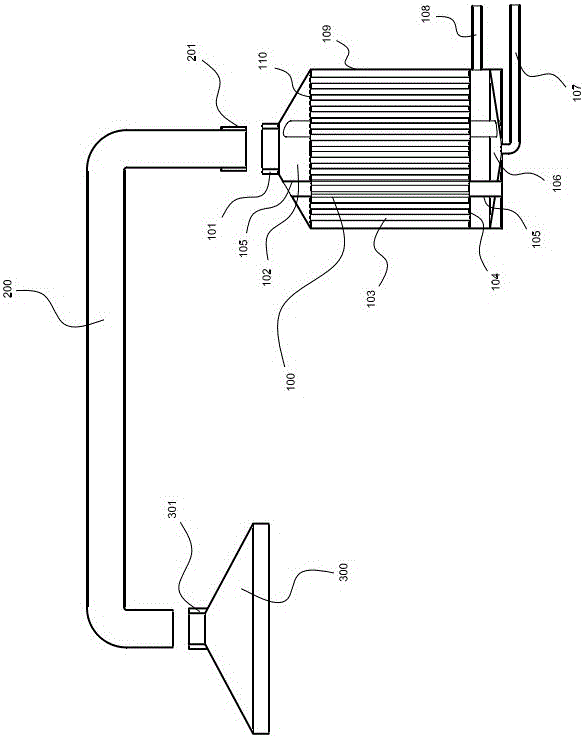

[0035] Such as Figure 1-3 As shown, this embodiment includes a distiller (300, 400) containing wine grains, a wine vapor pipe 200 that guides wine vapor from the still (300, 400) into the condenser 100, and wine vapor that is introduced into the wine vapor pipe 200 A condenser 100 for condensing, and a blower and an air duct for blowing air into the distiller. The still includes a distillation barrel 400 and a distillation cover 300 covering the distillation barrel 400 .

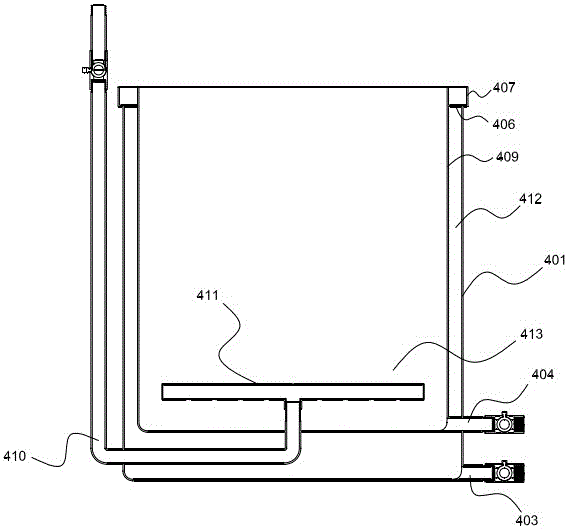

[0036] Such as figure 1 , figure 2 As shown, the distillation barrel 400 is provided with a cylindrical inner barrel 409 and a cylindrical outer barrel 401 , and the inner barrel 409 is sleeved in the outer barrel 401 . The inner barrel 409 and the top of the outer barrel 401 are airtightly connected by a ring-shaped plate 406, the outer peripheral edge of the ring-shaped plate 406 is welded to the lower end of a cylindrical surface plate 407, and the ring-shaped plate 406, the cylindrical surface plate...

Embodiment 2

[0043] refer to figure 1 , figure 2 , Figure 4 , this embodiment includes a distiller (300, 400) for containing wine grains, a wine vapor pipe 200 that guides the wine vapor from the still (300, 400) into the condenser 100, and condenses the wine vapor introduced by the wine vapor pipe 200 Condenser 100, and a blower for blowing air into the distiller, air guide pipe and air guide loop pipe. The still includes a distillation barrel 400 and a distillation cover 300 covering the distillation barrel 400 .

[0044] Structural reference of distillation barrel 400 figure 1 , figure 2 Shown and written description of Example 1.

[0045] Structural references for blowers and air ducts figure 1 , figure 2 Shown and written description of Example 1.

[0046] Such as Figure 4 As shown, a water jacket 303 is provided above the distillation cover 300 , a water inlet 302 is provided below the water jacket 303 , and a water outlet 304 is provided above. The top of the water jac...

Embodiment 3

[0050] refer to image 3 , Figure 5 , Figure 6 , the present embodiment includes a distiller for containing wine grains, a wine vapor pipe 200 for leading wine vapor from the still to a condenser 100, a condenser 100 for condensing the wine vapor introduced by the wine vapor pipe 200, and a steam pipe for distilling The air blower and the air duct for blowing air into the device. The still includes a distillation barrel and a distillation lid 300 that covers the distillation barrel.

[0051] Refer to the structure of the distillation cover 300, the wine vapor tube 200, and the condenser 100 image 3 Shown and written description of Example 1.

[0052] Such as Figure 5 , Figure 6 As shown, the distillation barrel is provided with a cylindrical inner barrel 409 and a cylindrical outer barrel 401 , and the inner barrel 409 is sleeved in the outer barrel 401 . The inner barrel 409 is airtightly connected with the top of the outer barrel 401 through a ring-shaped plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com