Rotating disc type granulating tank device for hot steel slag

A hot-state steel slag and rotating disc technology, which is applied in the field of hot-state steel slag rotating disc type granulation tank device, can solve the problems of incomplete separation of slag and steel, large crushing particle size of steel slag, environmental pollution, etc., so as to reduce the cost of crushing and processing Cost, effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

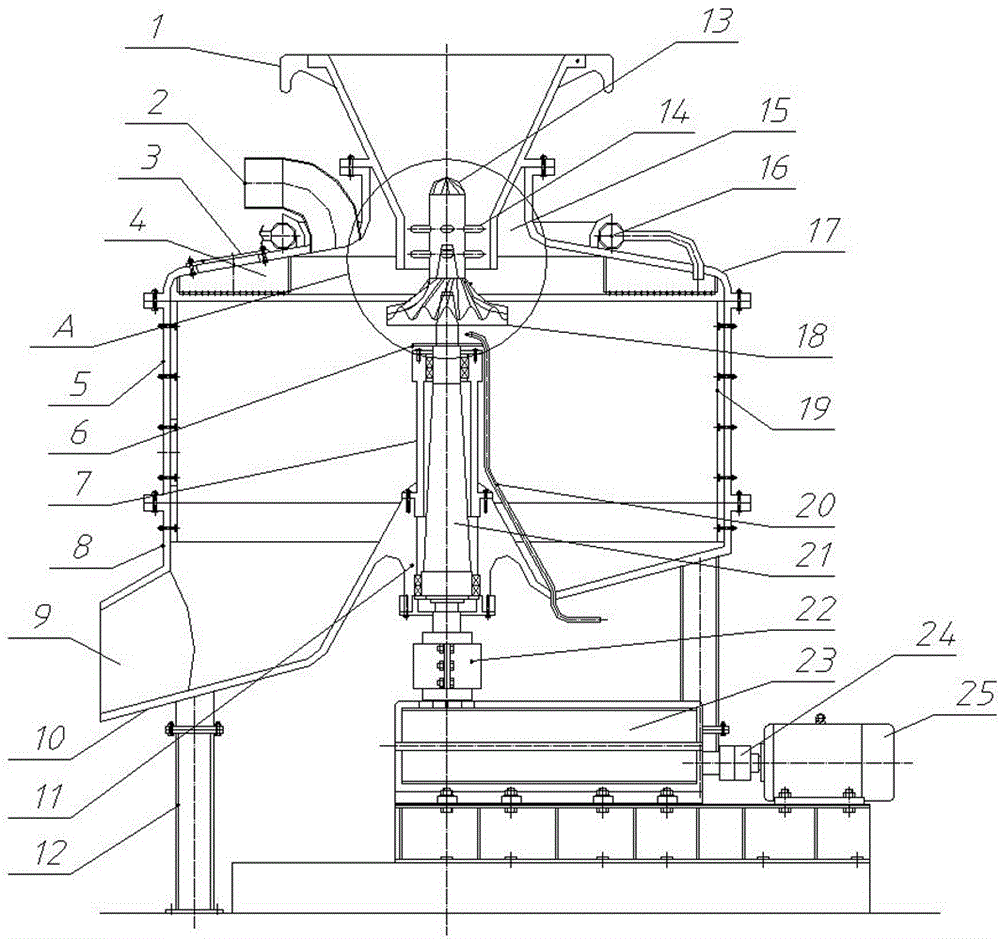

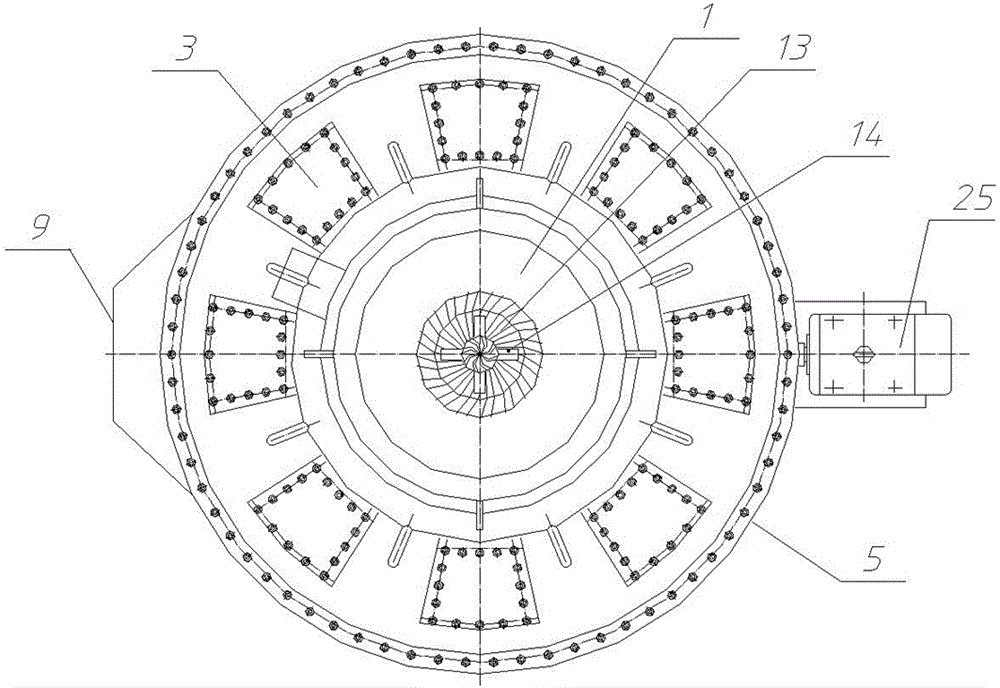

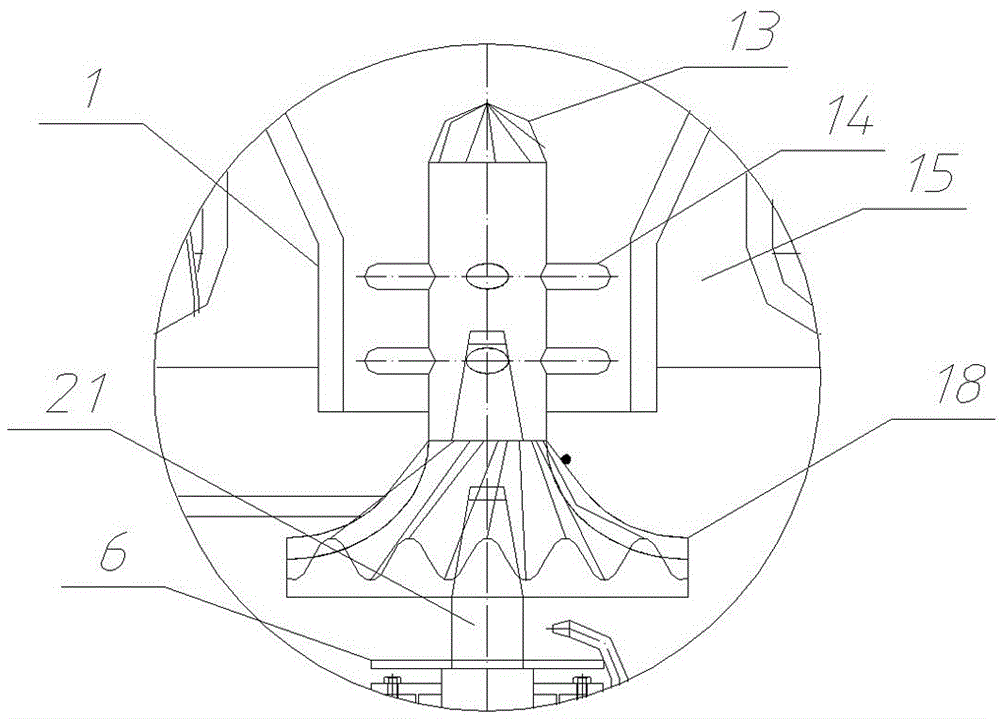

[0024] see figure 1 , figure 2 , image 3 , the tank body includes an upper top cover 17, a middle water quenching section cylinder body 5, and a lower discharge section shell 8, and a flange is passed between the top cover 17, the water quenching section cylinder body 5, and the discharge section shell 8 The connection is integrated, the material of the flange is ZG270-500, the upper part of the top cover 17 is provided with a feed port 15, and the position of the feed port 15 of the top cover 17 is connected with a cone hopper 1 through a flange, a cone hopper 1, and a top cover 17 , the cylinder body 5 of the water quenching section, and the casing 8 of the discharge section are all made of round cast steel, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap