Device and method capable of horizontally improving directional solidification purification yield of polycrystalline silicon

A technology of directional solidification and polysilicon, which is applied in chemical instruments and methods, polycrystalline material growth, crystal growth, etc., can solve the problems of lower product yield, low impurity removal rate, and easy reverse solidification in impurity regions, so as to improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

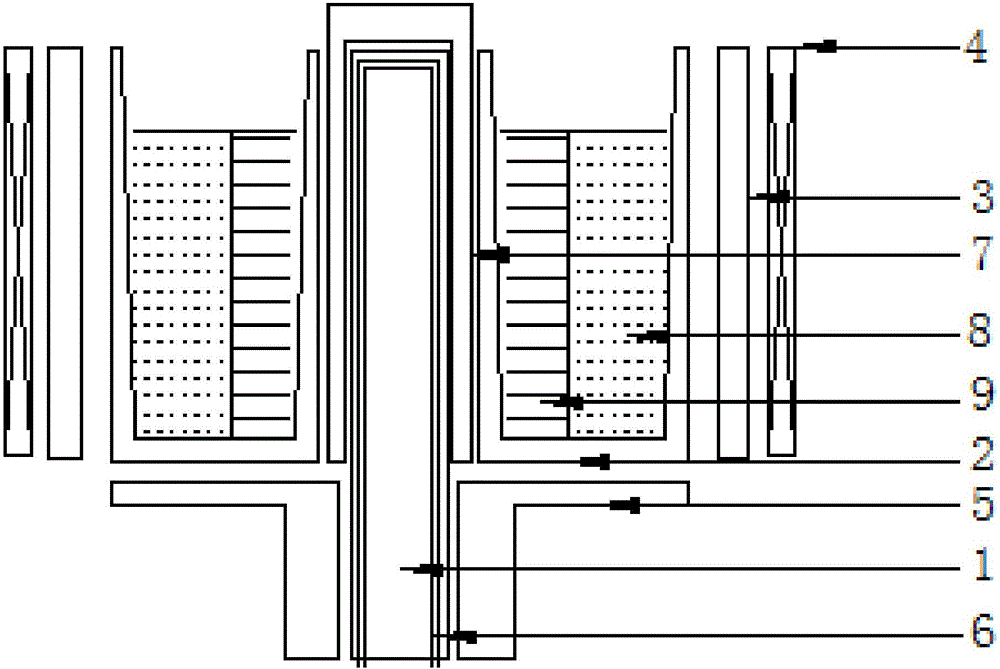

[0024] Such as figure 1 with figure 2 As shown, a device for improving the directional solidification and purification rate of polysilicon laterally comprises a water-cooled column 1, an annular graphite crucible 2 is arranged on the outside of the side wall of the water-cooled column 1, the water-cooled column 1 and the annular graphite crucible 2 Axes are located on the same straight line, and the side wall outside of described annular graphite crucible 2 is provided with annular heating body 3, and the side wall outside of described annular heating body 3 is provided with annular heating body 4, and the bottom of described annular graphite crucible 2 is provided with The tray 5 is rotated, and the water cooling column 1 is provided with a circulation channel 6 .

[0025] The material of the water-cooling column 1 is copper, and the outer wall of the water-cooling column 1 is provided with a sheath 7, and the sheath 7 is a graphite sheath.

[0026] The annular heating ele...

Embodiment 2

[0030] A method of using the equipment described in embodiment 1 to laterally improve polysilicon directional solidification purification yield has the following steps:

[0031] S1. Place the silicon material in the annular graphite crucible 2, evacuate the reaction space to 0.1-3Pa and then pour in flowing argon to make the pressure in the reaction space 60000-120000Pa. The annular heating body 4 is heated at 10°C Heat the annular heating element 3 to 1550°C at a heating rate of 1 / min, and keep it warm for 0.5-1h to obtain a completely melted silicon melt 8;

[0032] S2. Cooling water is poured into the circulating channel 6, and the temperature of the annular heating element 3 uniformly decreases to 1450° C. within 20 minutes. After the polysilicon 9 begins to nucleate inside the annular graphite crucible 2, the The annular graphite crucible 2 rotates with the rotating tray 5 at a speed of 1-300r / min, and at the same time, the annular heating element 3 cools at a cooling rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com