A preparation method and device for microfluidic ultrafine fibers in a polymer melt film

A microfluidic and polymer technology, which is applied in fiber processing, stretch spinning, textiles and papermaking, etc., can solve the problems of low production efficiency, strong molecular curl, affecting fiber performance, etc., and achieve fast molding speed and reduced Flow resistance, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

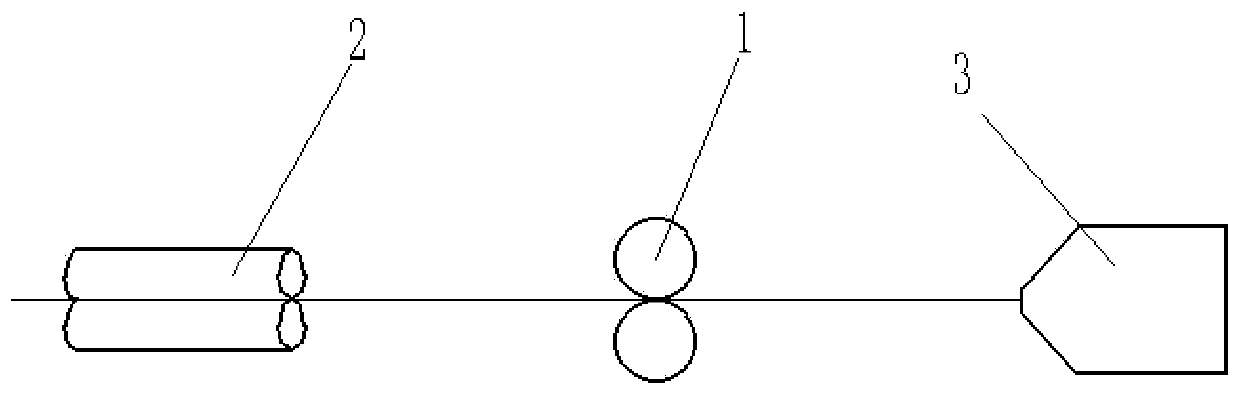

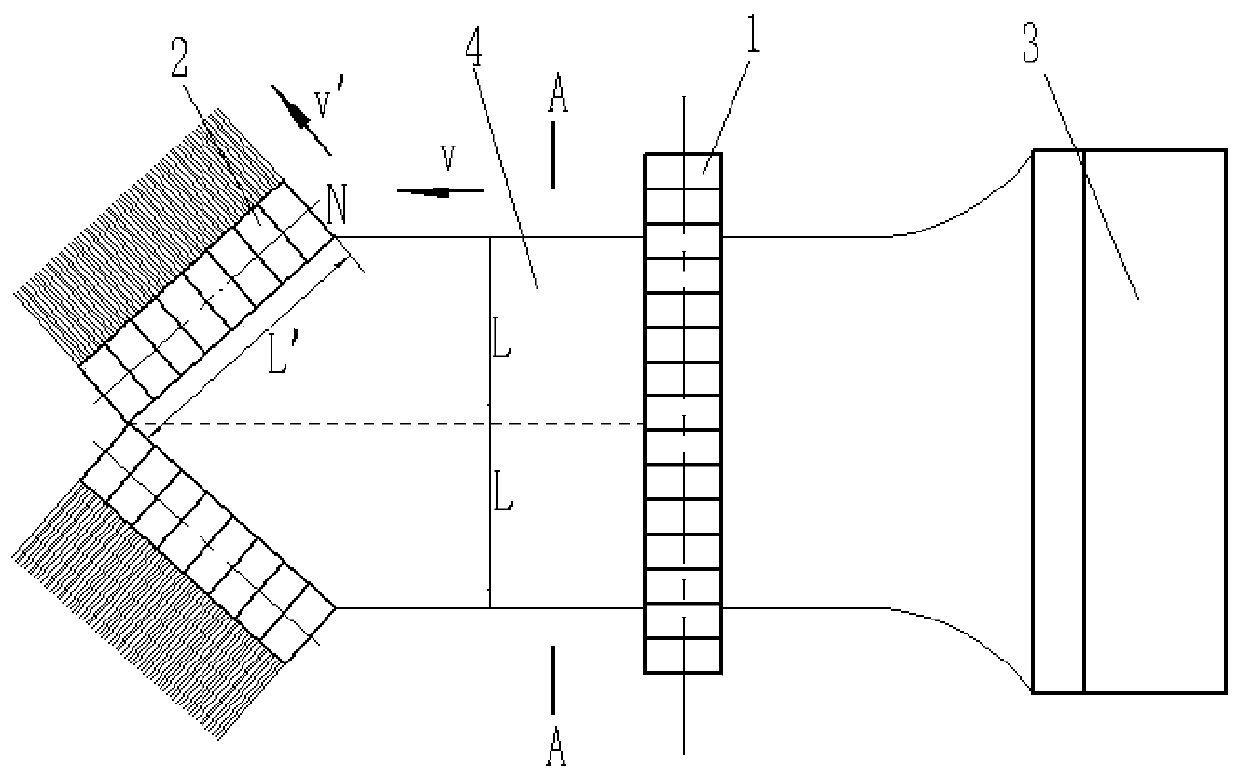

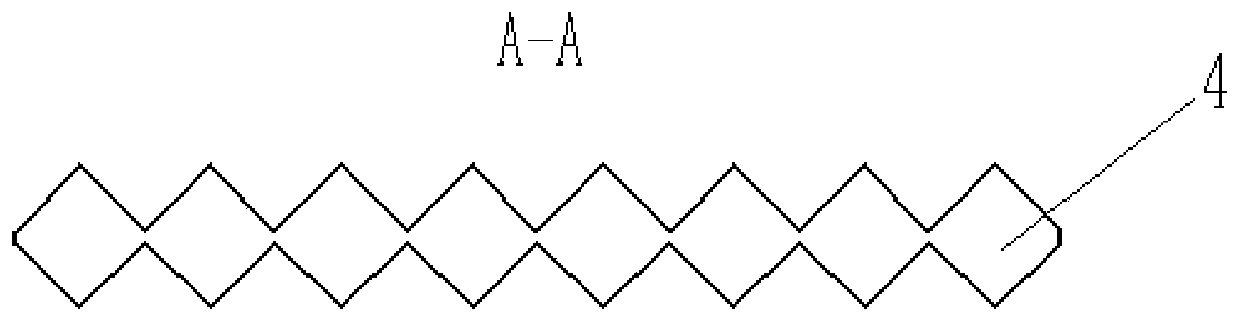

[0021] The invention provides a microfluidic superfine fiber manufacturing device in a polymer melt film, which is composed of a microfluidic extrusion unit and a traction stretching unit; wherein the microfluidic extrusion unit includes an upper die 33, a lower die Die 34, upper and lower die gap adjustment screw 35, microfluidic copper strip 36, such as Figure 4 Shown; Wherein the traction stretching unit comprises traction roll 1, transverse stretching nip roll 2, as figure 1 shown.

[0022] The invention discloses a method for manufacturing microfluidic superfine fibers in a polymer melt film. The molten PVC material extruded into the hanger-type sheet head by an extruder enters the flow channel between the upper die 33 and the lower die 34. , the molten PVC material flows from the middle to both sides along the hanger-shaped flow channel, passes through the microfluidic copper strip 36 installed at the upper and lower positions of the extrusion lip, extrudes a PVC film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com