Design method for cutter head of laser full fracture surface rock tunnelling machine

A design method and laser disc technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., to achieve the effects of convenient removal, reduced vibration, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

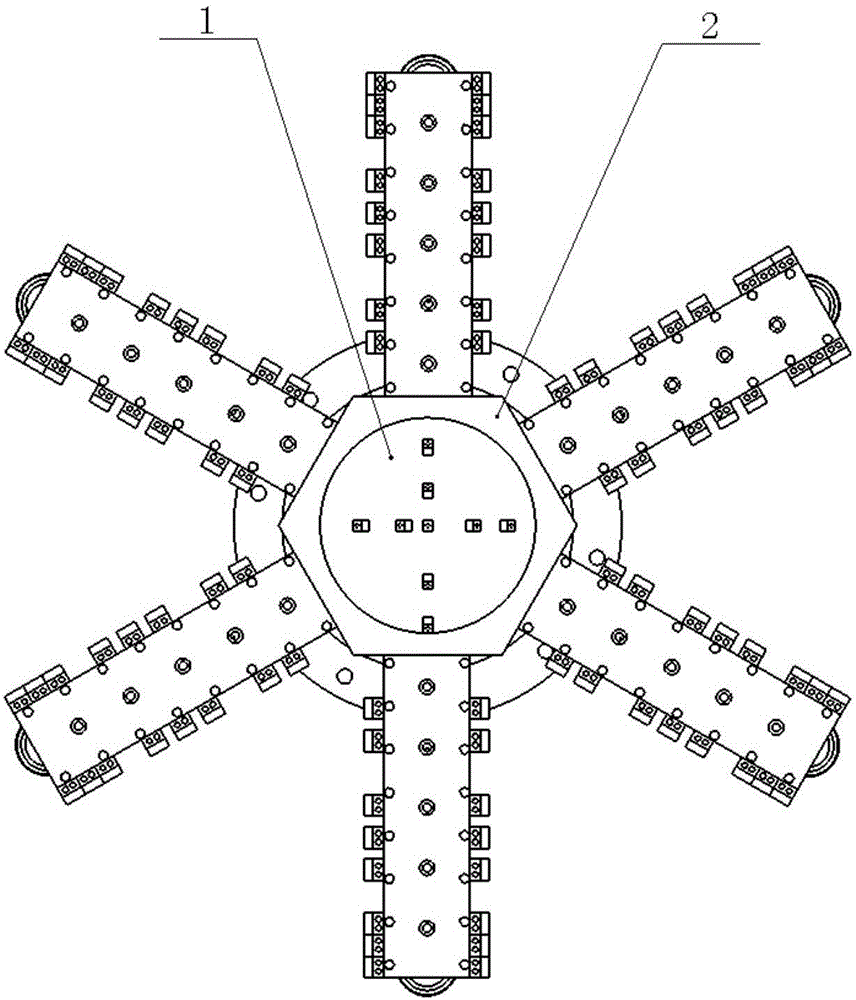

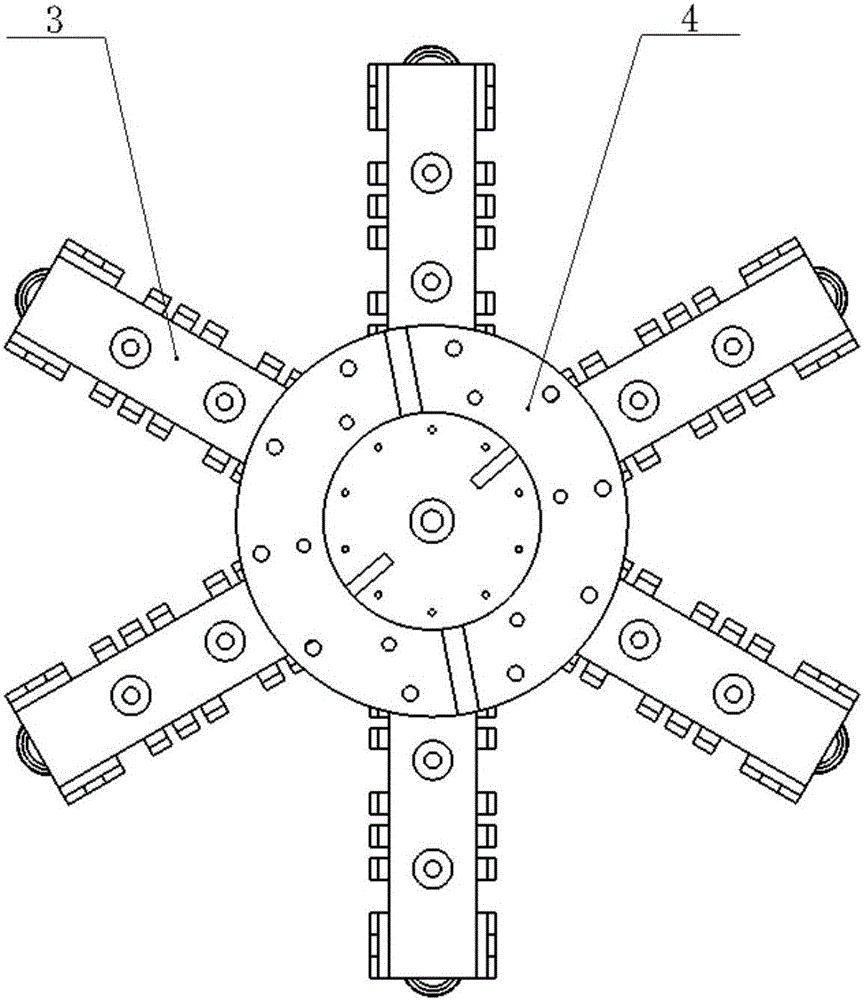

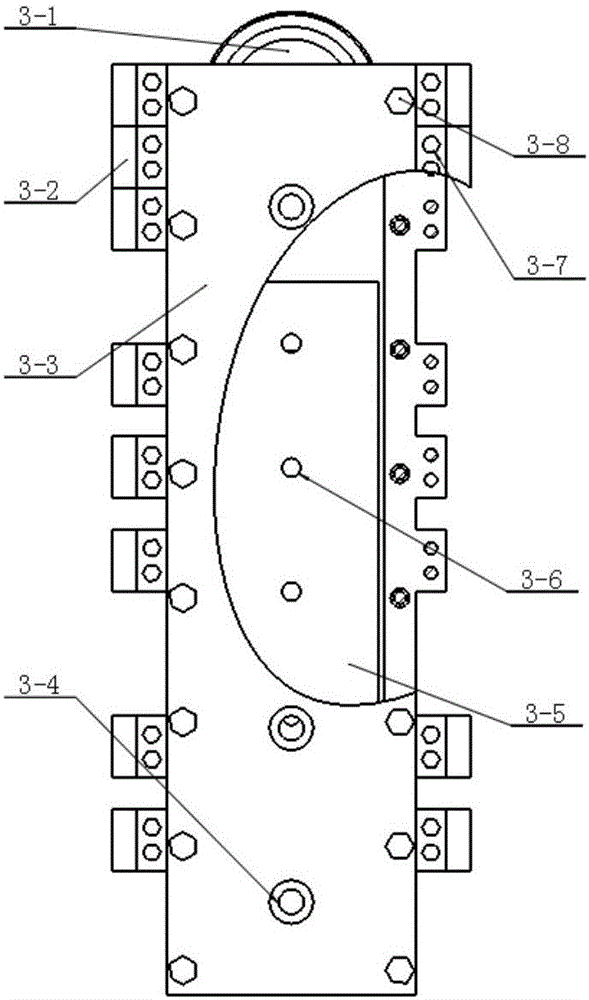

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0031] The traditional full-face rock boring machine uses the overall rotation of the cutter head to make the hob continuously squeeze the rock. When the stress exerted by the hob on the rock is greater than the ultimate stress of the rock, the rock will produce cracks and break. To achieve the effect of breaking rocks. During this process, the hob is directly in contact with the rock, and the vibration generated by breaking the rock will be transmitted to the entire cutter head through the hob, and the resulting vibration is huge, which seriously affects the stability and reliability of the roadheader. sex.

[0032]The invention adopts laser and high-pressure water gun to break rock together, so that most of the working time of the roadheader is not in direct contact with the rock surface, so the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com