Split type secondary grouting system of shield tunneling machine

A technology of secondary grouting and shield machine, applied in the field of shield machine, can solve the problems of working space affecting manual operation, limited width of equipment bridge walking platform, large volume of cement liquid tank, etc., to achieve high construction efficiency and construction preparation. The effect of short time and large work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

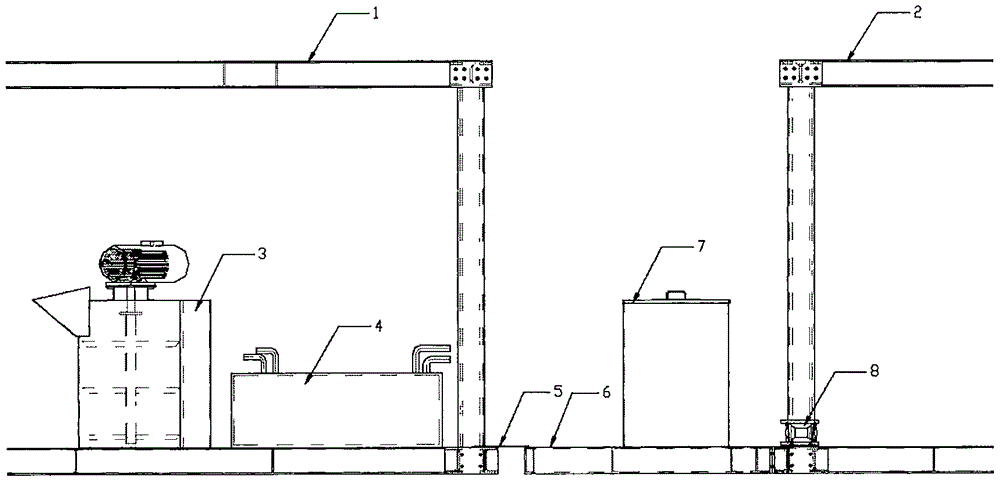

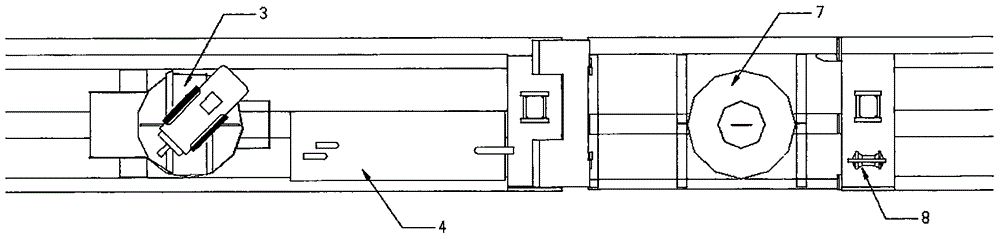

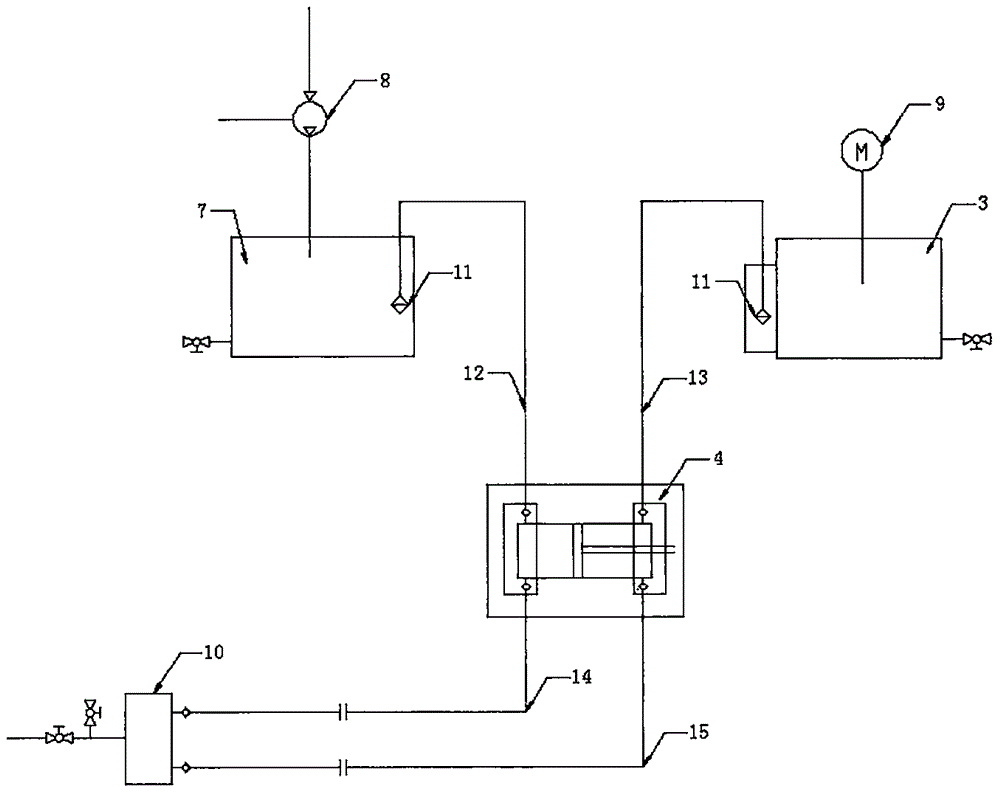

[0023] like figure 1 , 2 As shown, a shield machine split secondary grouting system includes a cement liquid tank 3, a water glass liquid tank 7, a double liquid grouting pump 4 and a double liquid mixer 10 for the secondary grouting operation;

[0024] The cement liquid tank 3, the water glass liquid tank 7 and the double liquid grouting pump 4 are all installed on the tail end of the trailer of the shield machine;

[0025] The double-liquid grouting pump 4 is installed in the middle of the cement liquid tank 3 and the water glass liquid tank 7, and the double-liquid grouting pump 4 is connected to the cement liquid tank 3 and the water glass liquid through the grout suction hoses 12 and 13 respectively. tank 7, the double-liquid grouting pump 4 is connected to the double-liquid mixer 10 installed near the grouting hole through the grout disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com