Road tunnel crossing inclined coal seam goaf ground pre-treatment method

A technology for road tunnels and goafs, applied in the field of ground pretreatment of goafs where road tunnels cross inclined coal seams, can solve the problems of narrow construction space, low drilling and grouting efficiency, etc., to ensure construction safety and eliminate potential safety hazards , The effect of facilitating grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

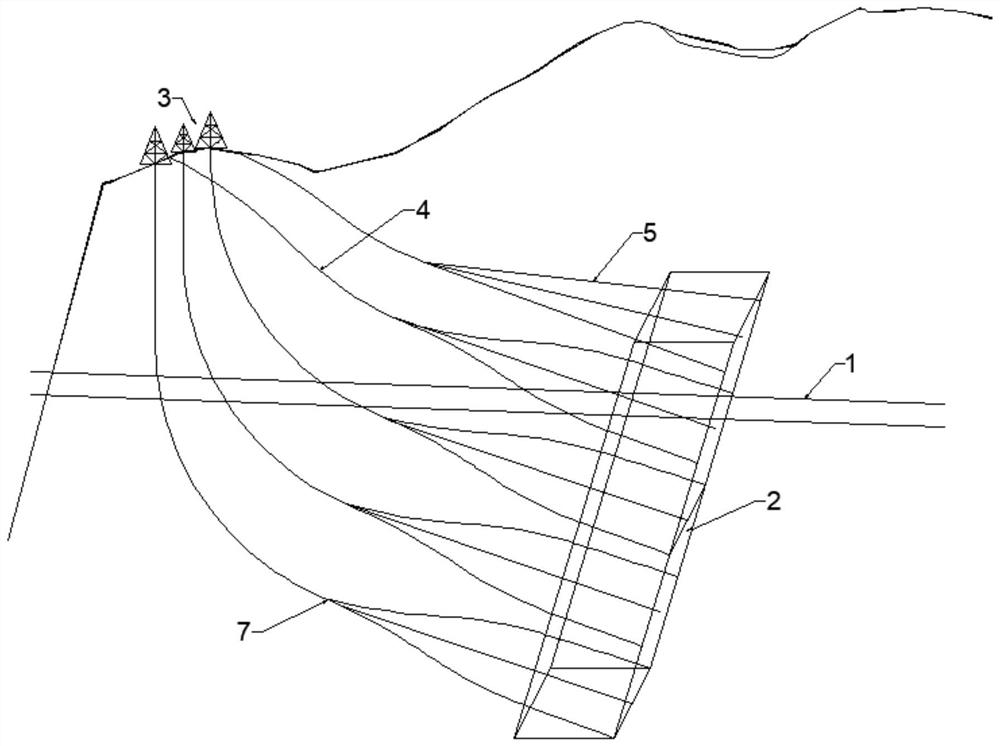

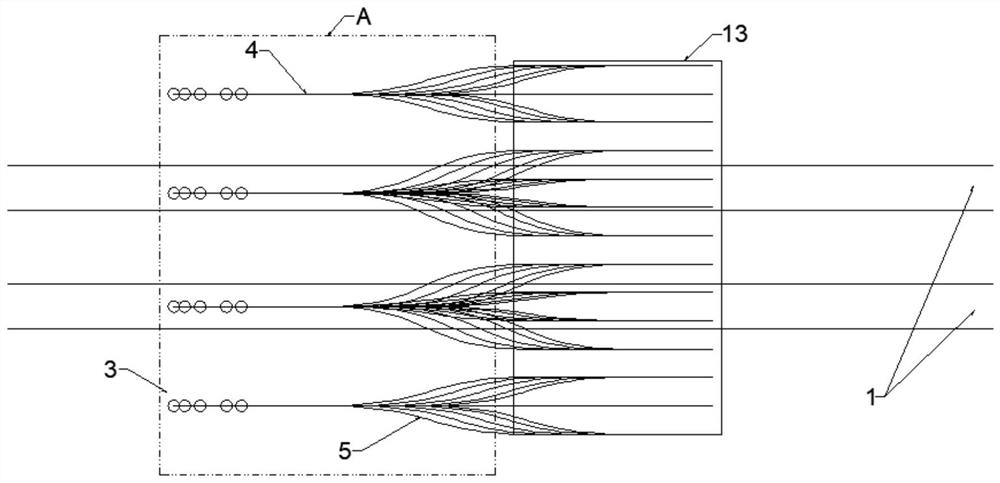

[0040] In this embodiment, the tunnel section is a two-way road tunnel (such as figure 1 As shown in the engineering test point, according to the construction planning design, the highway tunnel cohables 10 layers of inclined coal seam taking space, and the method of inclined coal seams crossing the highway tunnel is taken as a surface prevention.

[0041] In this embodiment, the road tunnel transversely cuts the surface prevention method of tilt coal seam, including the following steps:

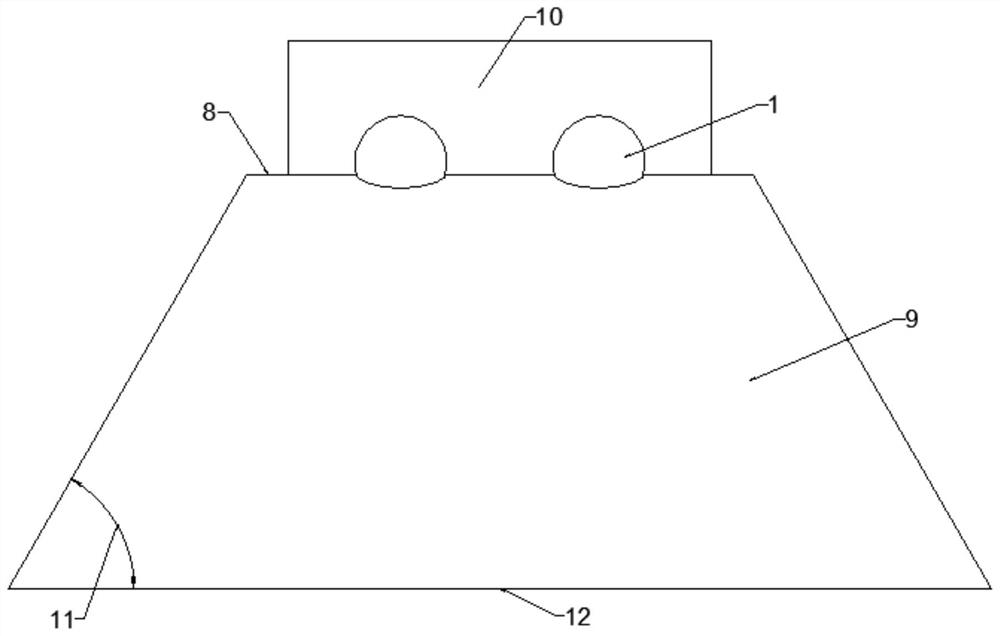

[0042] Step A: Exploring the vacuum area, determine the governance of the tilt area of the tilt coal seam of 10; when determining the governance of the vacuum area 13, those skilled in the art can also combine the feature of override migration And engineering experience, comprehensively determine the scope of governance of the vacuum area; the scope of the governance area 13 includes a road tunnel under the road tunnel 9 and the upper vacuum area of the highway tunnel 10;

[0043] The determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com