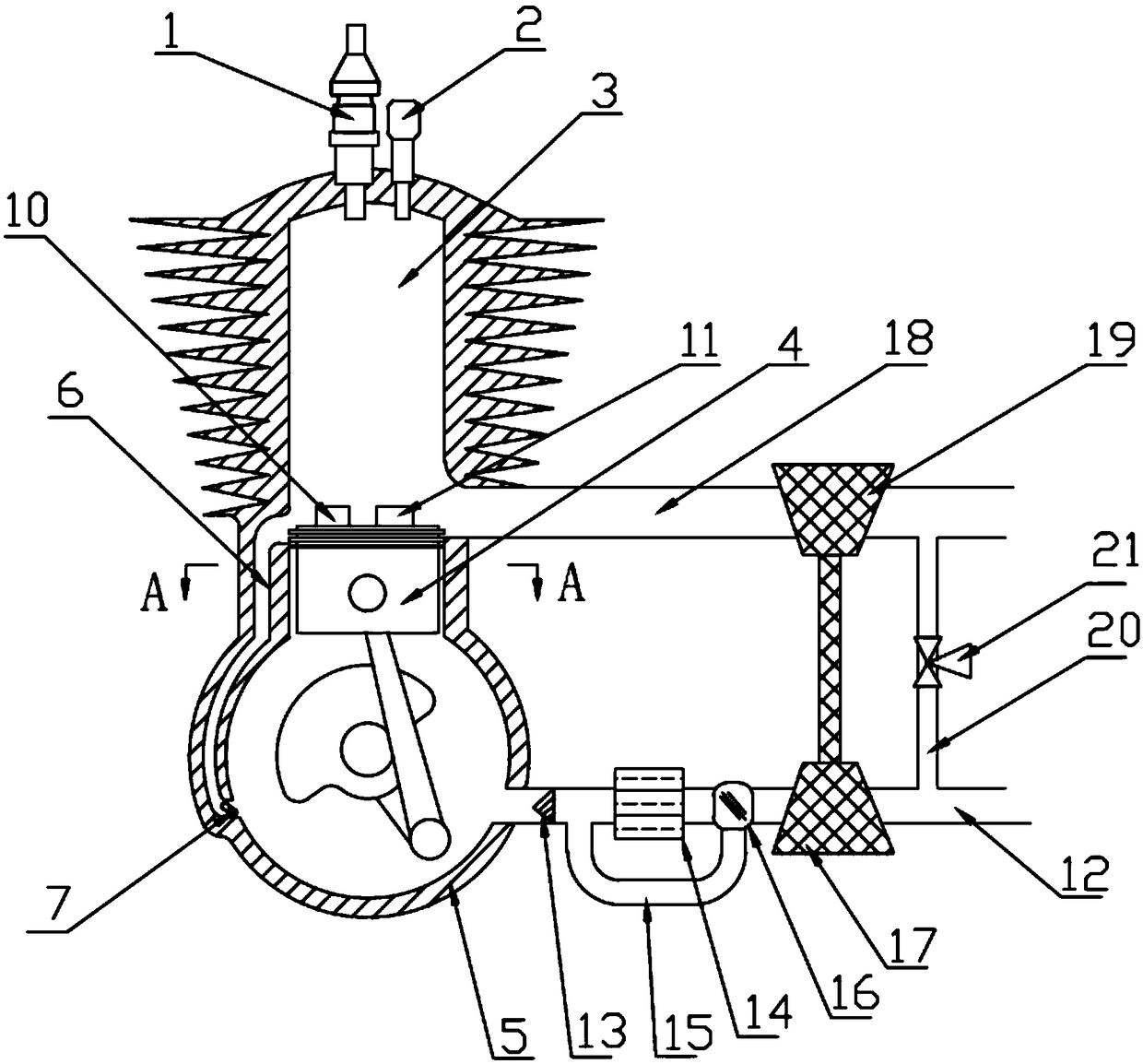

A high compression ratio two-stroke gasoline compression ignition device and control method

A high compression ratio, two-stroke technology, applied in engine control, charging system, combustion engine, etc., can solve uninvolved problems, reduce mixing, reduce scavenging dead zone, and improve air exchange quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

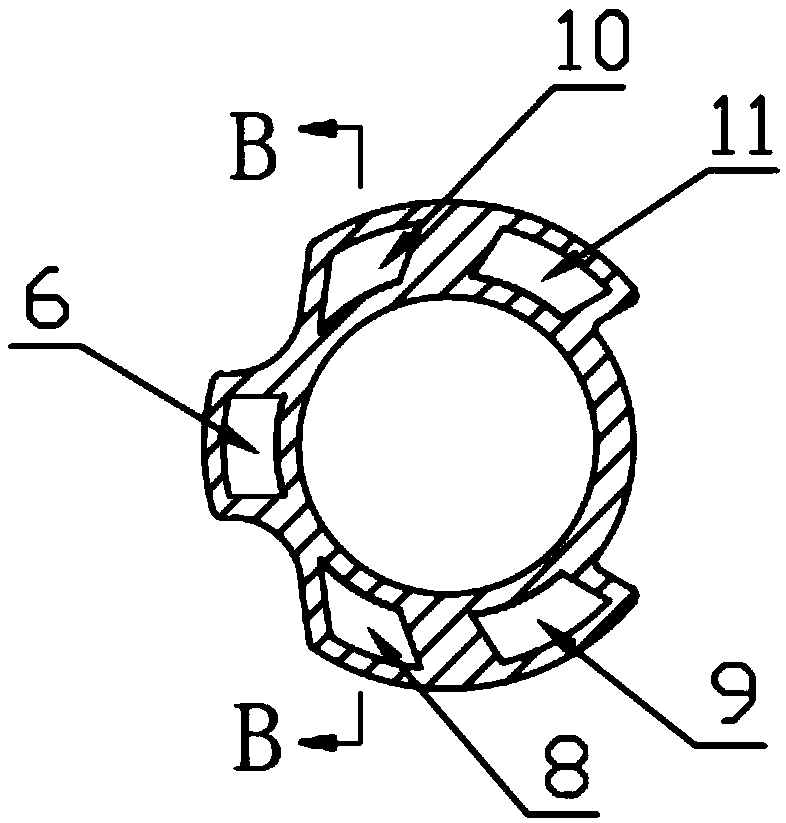

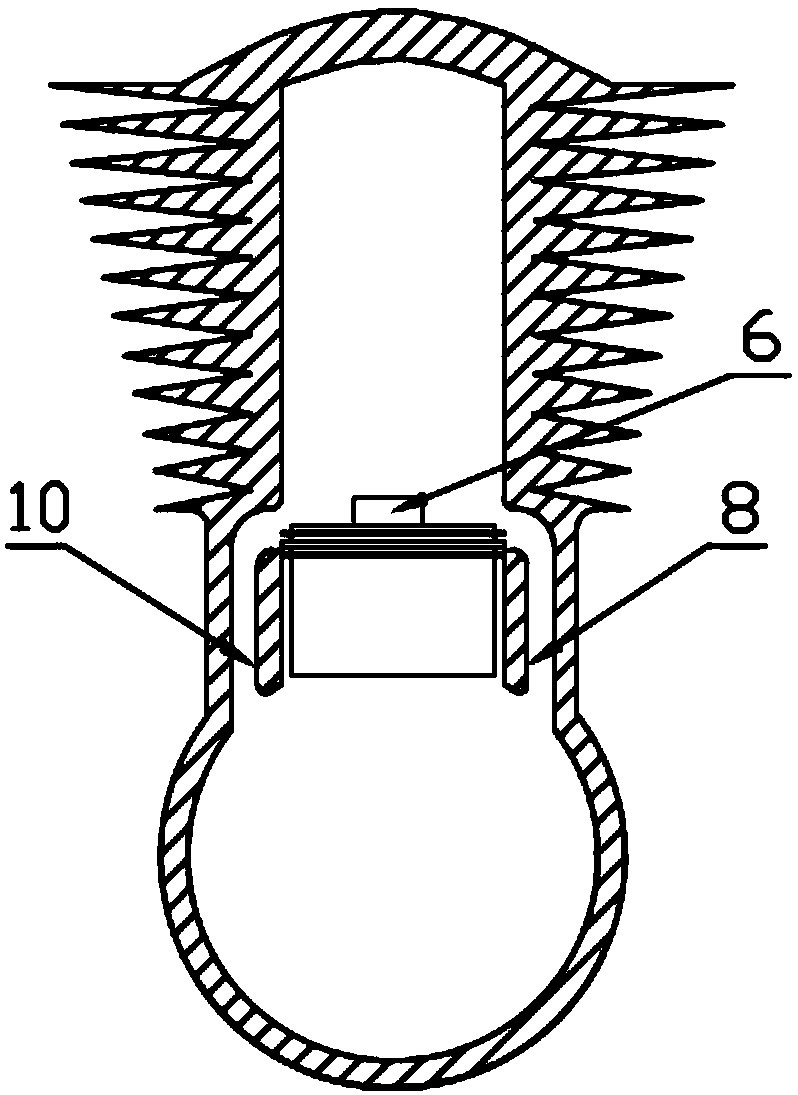

Embodiment 1

[0033] (1) When starting cold, the electronic control unit ECU controls the glow plug 2 to heat the mixture in the cylinder, and the glow plug 2 does not work under non-cold start conditions. The ECU controls the intake control valve 16 to open to the intake bypass pipe 15, controls the long scavenging channel valve 7 to close, and controls the external exhaust gas recirculation valve 21 to close. When the piston is near the top dead center, the volume of the crankcase 5 increases, the pressure in the crankcase 5 decreases, the reed valve 13 opens, fresh air flows in from the inlet of the intake pipe 12, and is pressurized by the compressor 17. Then through the intake control valve 16, the intake bypass pipe 15 and the reed valve 13, the crankcase 5 is charged for the first time; When the upper opening of the fourth scavenging passage 11 is opened, the fresh air of the crankcase enters the cylinder scavenging air from the first scavenging passage 8, the second scavenging passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com