An electromagnetic brake with buffer structure

A technology of electromagnetic brake and buffer structure, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of brake failure and insufficient safety, so as to prevent failure, improve safety performance and brake effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

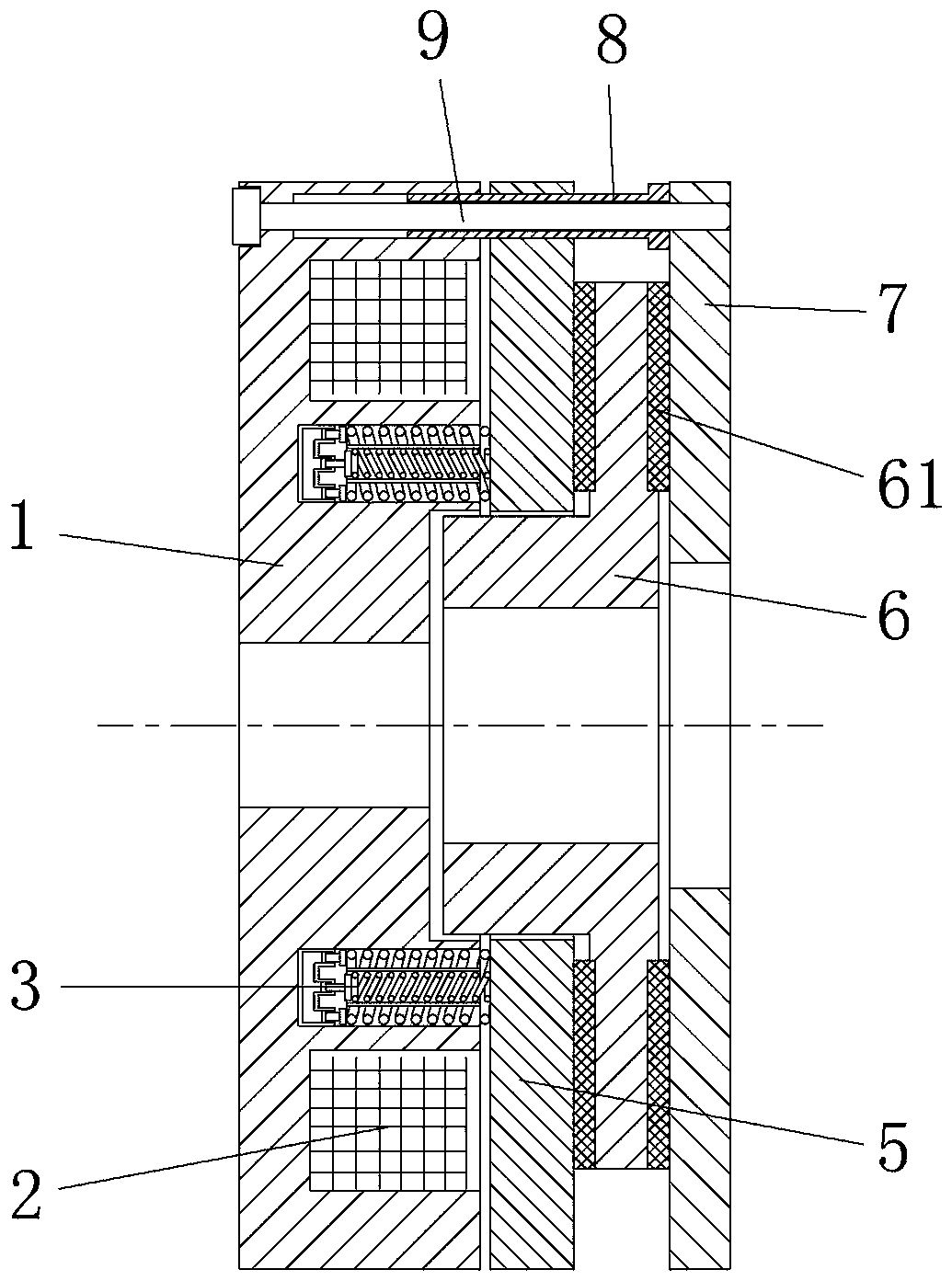

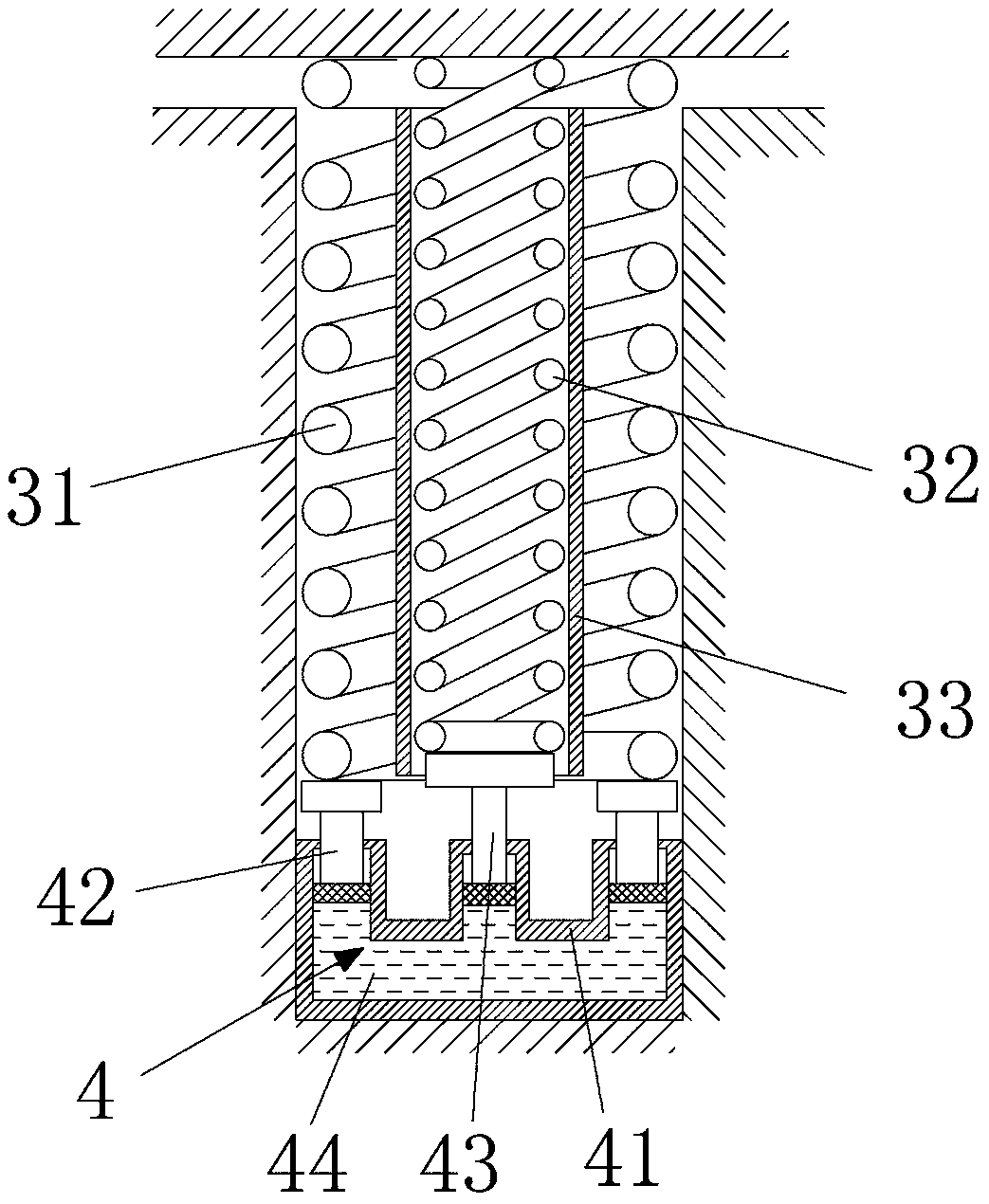

[0017] Example: such as figure 1 and figure 2 As shown, an electromagnetic brake with a buffer structure includes a yoke 1, a coil 2, an armature 5, a brake disc 6, a brake spring 3 and an end cover 7, and the brake disc 6 is arranged between the armature 5 and the Between the end covers 7 , friction plates 61 are provided on the left and right sides of the brake disc 6 , and the two ends of the brake spring 3 abut against the yoke 1 assembly and the armature 5 respectively, Make the armature 5 press the friction plate 61, the yoke 1 is provided with an installation groove, the coil 2 is arranged in the installation groove, and the yoke 1 is provided with a The installation hole of the spring 3, the brake spring 3 includes an outer spring 31, an inner spring 32 and a spacer 33, the spacer 33 is set on the outside of the inner spring 32, and the outer spring 31 is set on the spacer The outer side of the sleeve 33, the spacer sleeve 33 is an aluminum tube sleeve. The inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com