Electric cycle oil shock absorber

A technology of circulating oil and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of low response sensitivity and slow return speed, achieve shock absorption capacity guarantee, and improve return Speed, to avoid the effect of too slow return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

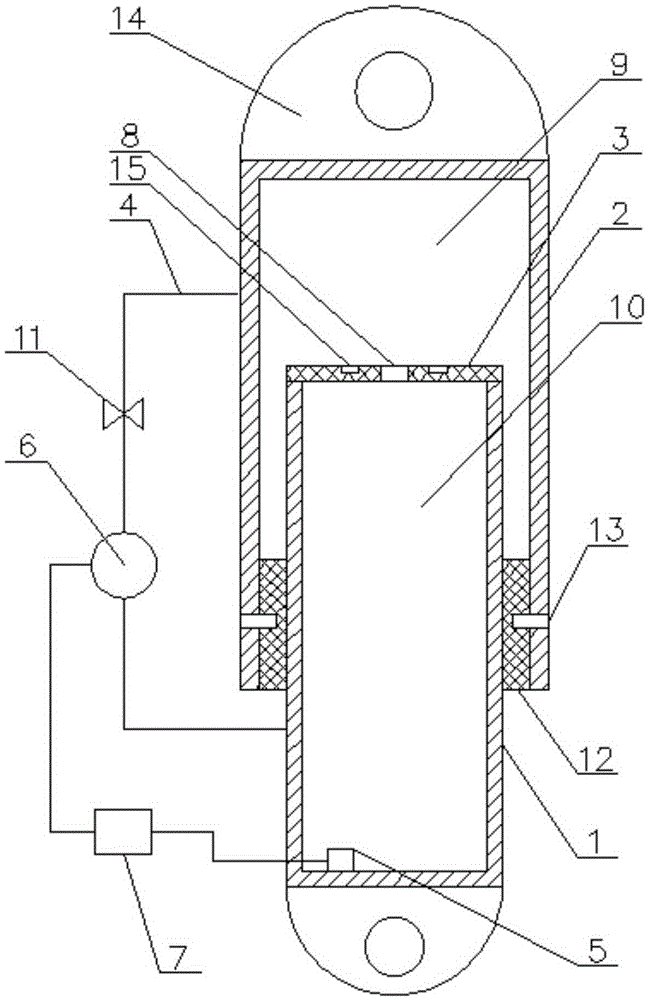

[0033] Such as figure 1 As shown, the electric circulating oil shock absorber includes an inner cylinder 1, an outer cylinder 2, a damping plate 3, a connecting hose 4, a pressure sensor 5, a hydraulic pump 6 and a controller 7; the upper end of the outer cylinder 2 is closed, and the outer The lower end of the cylinder body 2 is open, the upper end of the inner cylinder body 1 is open, and the lower end of the inner cylinder body 1 is closed; the damping plate 3 is arranged on the top of the inner cylinder body 1, and a damping hole 8 is opened on the damping plate 3; the inner cylinder body 1 is slidingly arranged on the outer In the cylinder body 2, the space between the top end of the inner cylinder body 1 and the top end of the outer cylinder body 2 constitutes the oil pressure space 9; the space in the inner cylinder body 1 constitutes the slow pressure space 10; the pressure sensor 5 is arranged in the inner cylinder body 1, The connecting hose 4 communicates with the i...

Embodiment 2

[0039] Such as figure 1 As shown, on the basis of Embodiment 1, the present invention also includes a one-way valve 11 arranged on the connecting hose 4 .

[0040] A one-way valve 11 is provided to prevent the oil from directly entering the pressure-relieving space 10 through the connecting hose 4 during compression of the present invention, so that the shock absorption capacity of the present invention is guaranteed.

Embodiment 3

[0042] Such as figure 1 As shown, this embodiment is based on Embodiment 2, and the check valve 11 is located between the hydraulic pump 6 and the outer cylinder 2 .

[0043] The one-way valve 11 is located between the hydraulic pump 6 and the outer cylinder 2 to prevent oil from entering the hydraulic pump 6 through the connecting hose 4 during compression, thereby protecting the hydraulic pump 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap