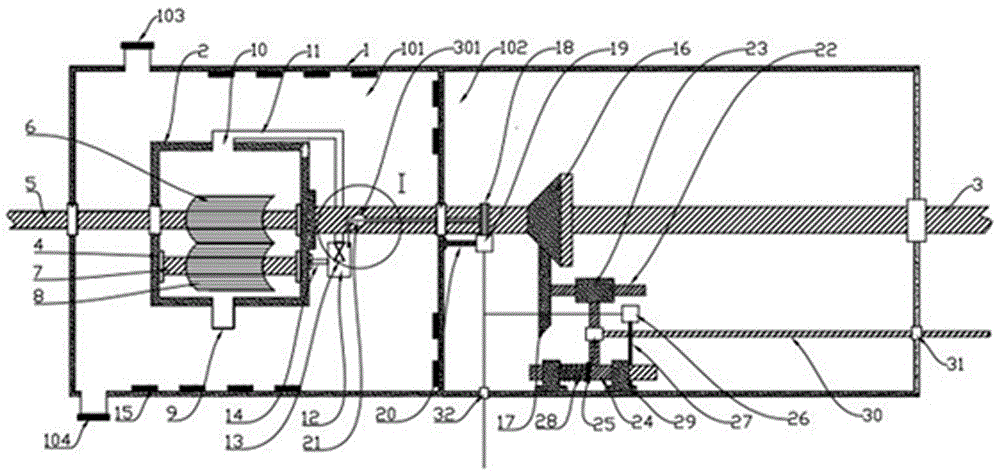

Hydraulic continuously variable transmission

A continuously variable transmission and hydraulic technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem that the power output of the power output end cannot be manually controlled, the differential ratio cannot be adjusted, and it is not easy to maintain, etc. problems, to achieve the effect of simple structure, improved riding comfort and light operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

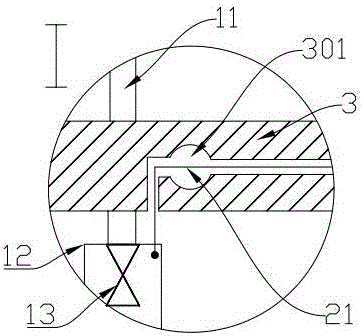

[0029] Embodiment: To further explain the working principle and working process of the present invention, first, a brief introduction is made to the gear pump. The basic form of the gear pump is that two gears with the same size are meshed and rotated in a closely matched housing. The diameter and both sides are closely matched with the shell. The material from the extruder enters the middle of the two gears at the suction port, and fills the space, moves along the casing with the rotation of the teeth, and finally is discharged when the two teeth mesh. A gear pump is also called a positive displacement device, that is, like a piston in a cylinder, when one tooth enters the fluid space of another tooth, the liquid is mechanically squeezed out, because the liquid is not easily compressed, so the liquid The teeth and teeth cannot occupy the same space at the same time, so that the liquid will be discharged. Due to the continuous meshing of the teeth, this phenomenon occurs conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com