Flashboard type vacuum sealing device

A vacuum sealing and gate technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy explosion of U-shaped sealing ring, inability to open the sealing plate, unreliable sealing, etc., to achieve simple structure and energy saving. The effect of good effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

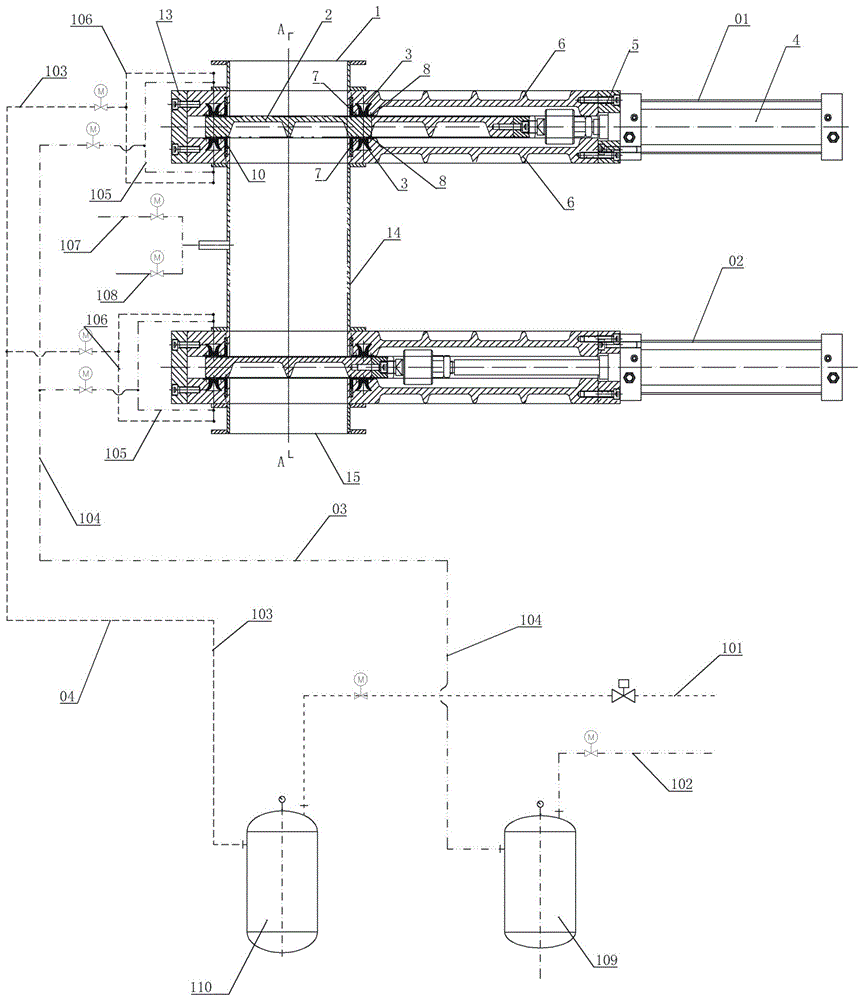

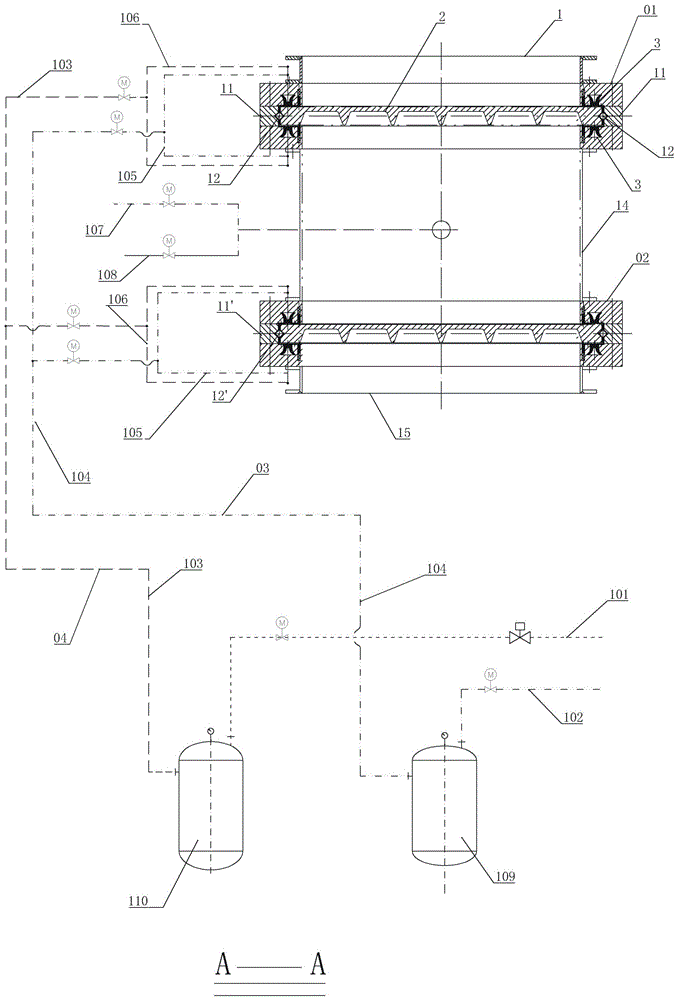

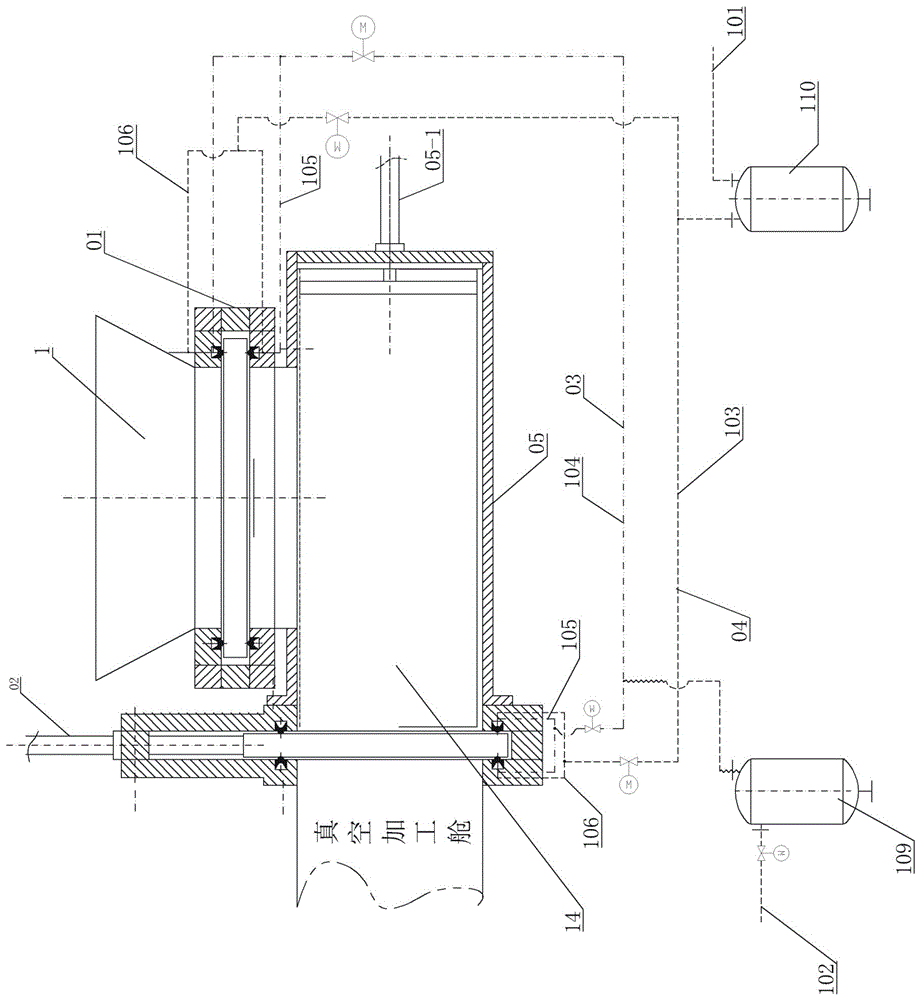

[0029] In the embodiment as shown in the figure, structure and work process of the present invention are:

[0030] The present invention forms the following three different forms of feeding and discharging methods through different combinations:

[0031] 1. The feeding and discharging form of the vertical ram-type vacuum sealing device for bulk materials;

[0032] 2. The feeding and discharging form of the bulk material or container straight-fall flat-push ram-type vacuum sealing device;

[0033] 3. The feeding and discharging form of the container right-angle horizontal push gate type vacuum sealing device.

[0034] 1. The feeding and discharging form of the vertical ram type vacuum sealing device for bulk materials:

[0035] Sealing valve group 01 is provided with sealing pressure plate 6, U-shaped sealing ring 3 is placed in the U-shaped sealing groove on sealing pressure plate 6, U-shaped sealing ring 3 is pressed by inner pressure plate 7 and outer pressure plate 8, scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com