Cooling system of LED light bar

A technology of LED light bars and cooling systems, applied in lighting devices, light sources, auxiliary controllers with auxiliary heating devices, etc., can solve problems such as high labor costs, low work efficiency and automation, and poor controllability, and achieve Improve production efficiency, save labor costs, and have high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

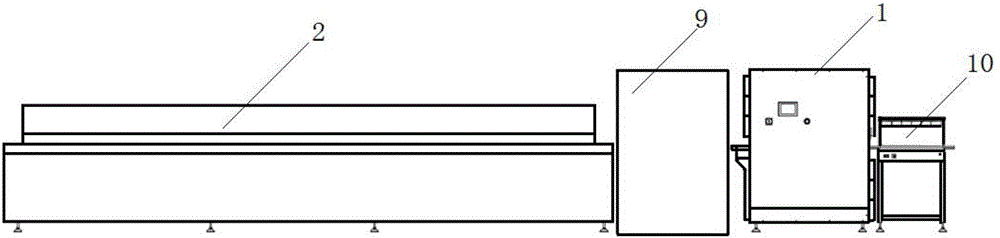

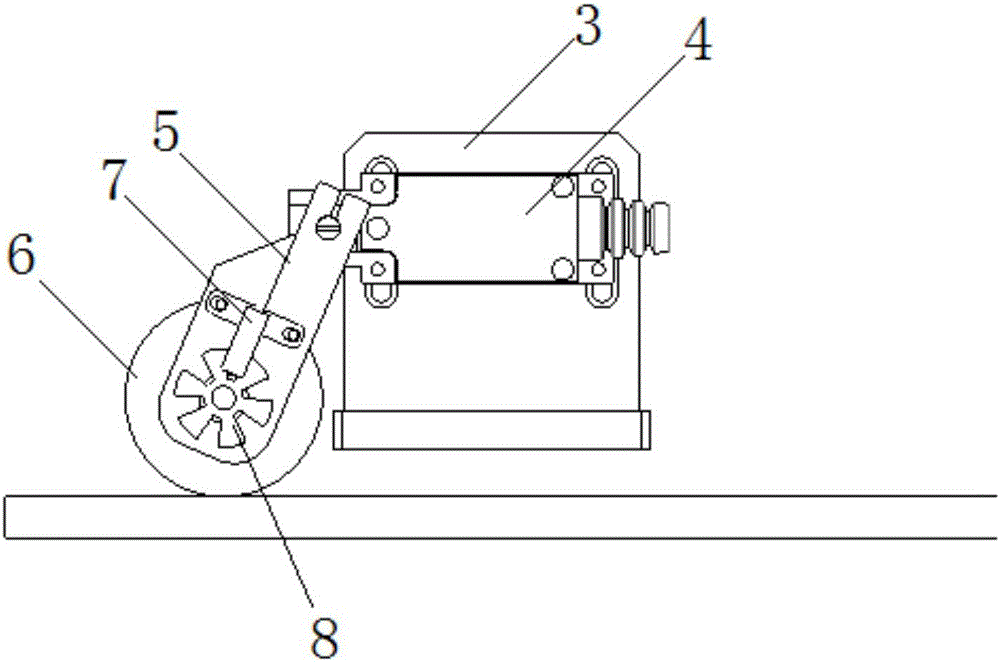

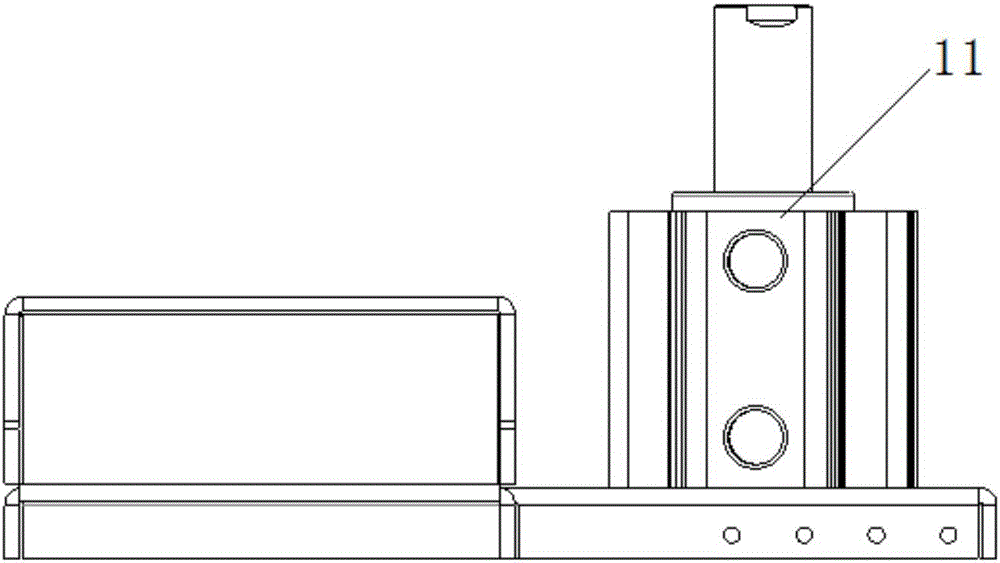

[0025] This embodiment provides an LED light bar cooling system, the system includes an automatic light bar cooling device 1 for cooling the welded LED light bar and a temperature control unit for controlling the welding and cooling process, the temperature control The unit is a control terminal such as a computer. The light bar automatic cooling device 1 has a cooling device body, and the cooling device body is provided with an accommodating cavity for accommodating the LED light bar to be cooled. The cooling device body has a feed end and a discharge end. The side wall of the accommodating cavity is provided with a cooling mechanism for reducing the surface temperature of the LED light bar. The cooling mechanism is electrically connected to the temperature control unit. The temperature control unit is a thermostat. The cooling time and surface temperature of the LED light bar in the light bar automatic cooling device After the temperature reaches the set value, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com