Integral plate core and manufacturing method thereof, heat collector and manufacturing method thereof

A manufacturing method and integrated technology, applied in the field of solar thermal collectors, can solve the problems of complex production process and poor anti-leakage of flat-plate solar thermal collectors, and achieve the advantages of preventing extrusion deformation, increasing strength, and avoiding welding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

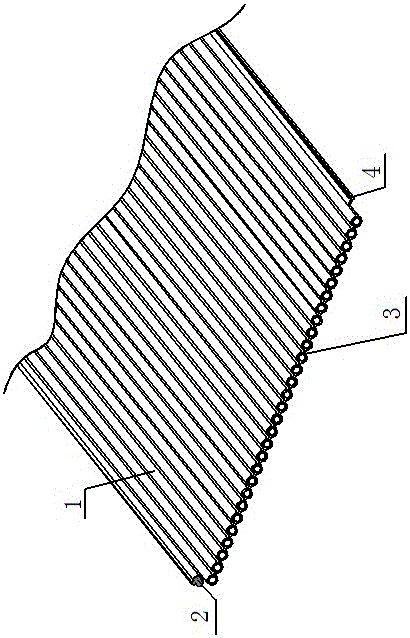

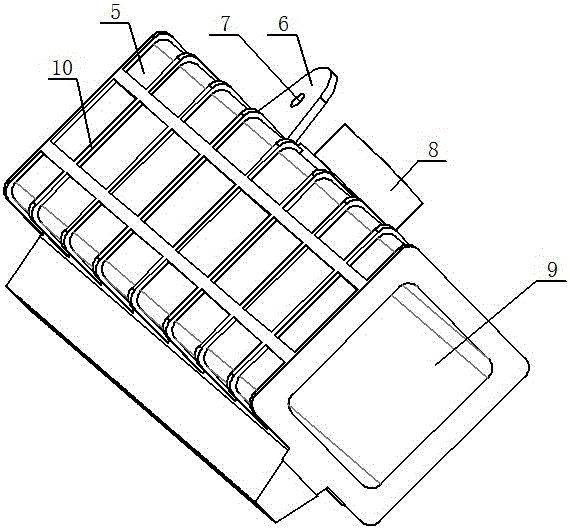

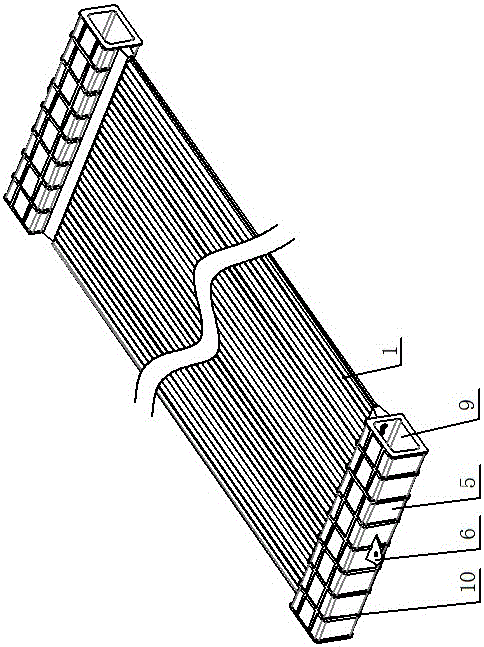

[0037] as attached figure 1 , attached figure 2 And attached image 3 As shown, the integrated plate core of the present invention includes a heat absorber 1 and a water collecting pipe 5. The heat absorber 1 is an extruded all-plastic integrated heat absorber. The heat absorber 1 includes a plug-in device and a plurality of vertical The heat-absorbing tubes 3 arranged at intervals, the above-mentioned multiple heat-absorbing tubes 3 form a sheet-like integrated structure in sequence from left to right, and the plug-in device includes a first plug-in piece 2 and a second plug-in piece 4 that are plug-fitted, The first socket 2 and the second socket 4 are relatively located at the left end and the right end of the plurality of heat-absorbing pipes 3, the first socket 2, the above-mentioned multiple heat-absorbing pipes 3 and the second socket 4 A heat absorber with an all-plastic integrated structure is formed; a mounting plate 6 with a mounting hole 7 is injected on one sid...

Embodiment 2

[0043] The manufacturing method of the integrated plate core in the manufacturing embodiment 1 of the present invention, the steps are:

[0044] (S1), using extrusion molding process to manufacture all-plastic integrated heat absorber 1, as attached figure 1 Shown, heat absorber 1 is the heat absorber in embodiment 1;

[0045] (S2), installing cores for manufacturing the water collecting pipe 5 on the upper end and the lower end of the heat absorbing body 1 respectively, and injecting the water collecting pipe 5 on the upper end and the lower end of the heat absorbing body 1 sequentially through an injection molding process, to obtain the water collecting pipe 5 in Example 1 One-piece core.

[0046] Wherein, in step (S2), the core includes a cylindrical mold body, and one side of the mold body is provided with a plurality of protrusions arranged in a row, and each protrusion can be connected to the mouth of the corresponding heat-absorbing pipe 3 9 plug fit. When the core i...

Embodiment 3

[0050] as attached Figure 4 As shown, the heat collector of the present invention includes a frame 12, a base plate 13, an insulating layer 14, a spacer layer 15, a core and a glass panel 15, the frame 12 is a hollow frame, and the spacer layer 15 is a reflective or barrier function. The spacer layer, the core body is the one-piece core body in embodiment 1, and the two nozzles 9 of the water collection pipe 5 in the one-piece core body are welded with end caps 11, bottom plate 13, insulation layer 14, spacer layer 15 and one body The type plate core is installed in the frame 12 sequentially from top to bottom, and the glass panel 15 is fixed on the frame 12.

[0051] Among them, the frame 12 is a frame made of polyvinyl chloride, the bottom plate 13 is a bottom plate made of polyvinyl chloride (English full name is Polyvinyl chloride, referred to as PVC) material; Polyurethane Foam (full name in English, referred to as PU) insulation layer; the spacer layer 15 can be select...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap