Rock experiment standard test piece drying and heat shrink tube baking device and operation method thereof

A standard test piece and heat shrinkable tube technology, applied in the field of rock experiment equipment, can solve problems such as the dislocation of the standard test piece and the base, uneven heating of the heat shrinkable tube, affecting the wrapping effect, etc., to improve the success rate, uniform heating, The effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

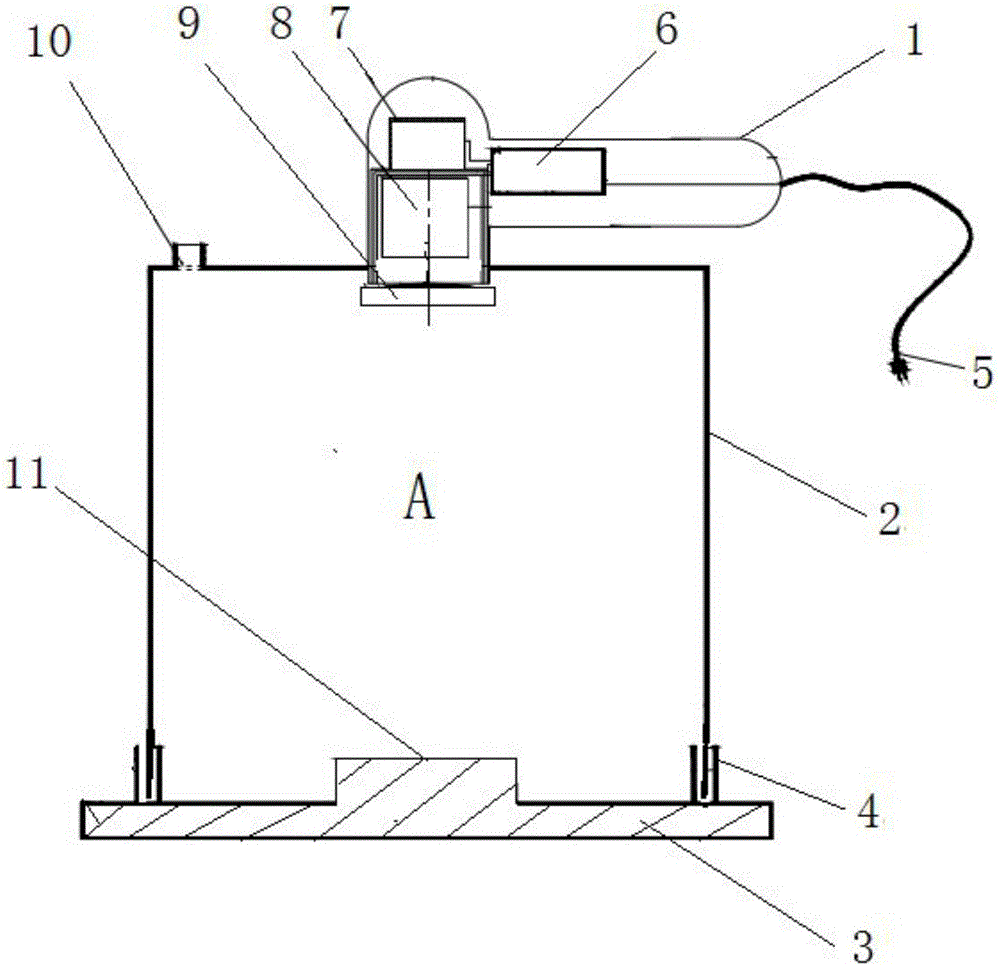

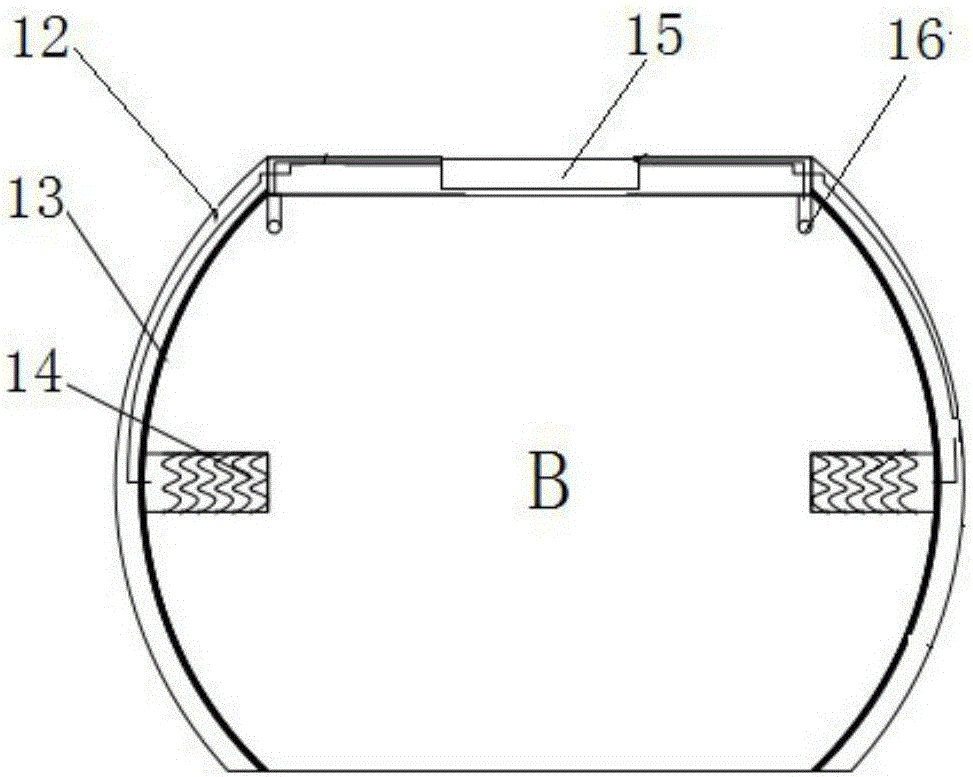

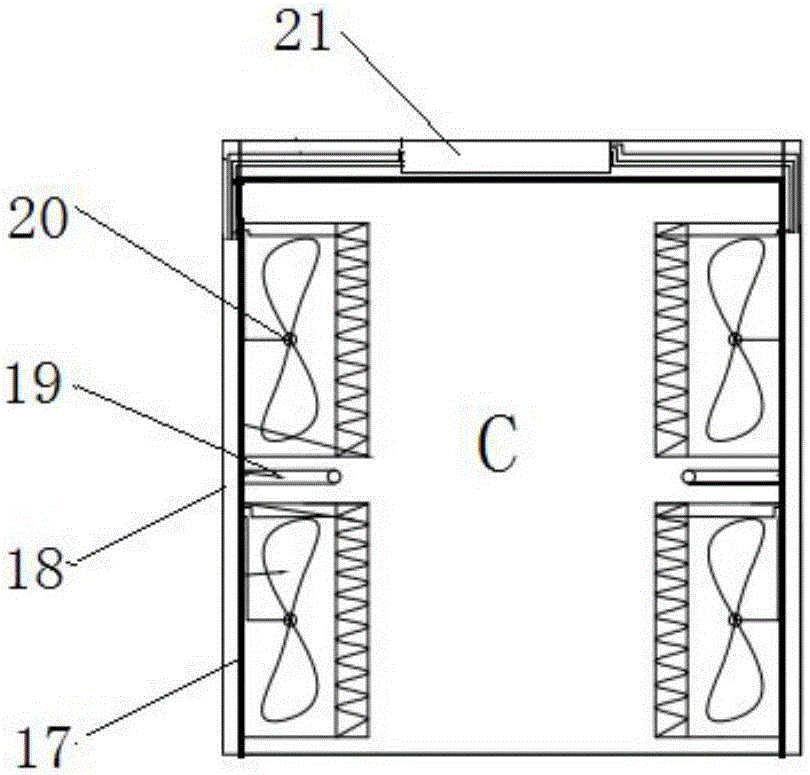

[0037] A rock experiment standard specimen drying and heat-shrinkable tube baking device, consisting of figure 1 The shown vacuum chamber A, figure 2 Shown in drying compartment B and image 3 The shown baking chamber C is composed; the drying chamber B can be placed in the vacuum chamber A for drying the rock standard specimen 22; the baking chamber C can be placed in the vacuum chamber A for baking the heat-shrinkable tube 27;

[0038] Such as figure 1 As shown, the vacuum chamber A is composed of a spoon-shaped operating handle 1, a vacuum cover 2 and a base 3; a circle of grooves 4 is arranged on the surface of the base 3, and the vacuum cover 2 and the base 3 are realized through the grooves 4. The sealed connection of the base 3 sides is provided with a placement platform 11 consistent with the diameter of the rock test standard specimen 22; the vacuum cover 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com