Thin film strain type torque sensor

A torque sensor and strain-type technology, which is applied in the field of thin-film strain-type torque sensors, can solve the problems of strain-type torque sensors such as hysteresis error, inability to work in harsh environments, and large temperature drift errors, and achieve temperature drift error reduction, temperature resistance and temperature resistance. Good long-term stability and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

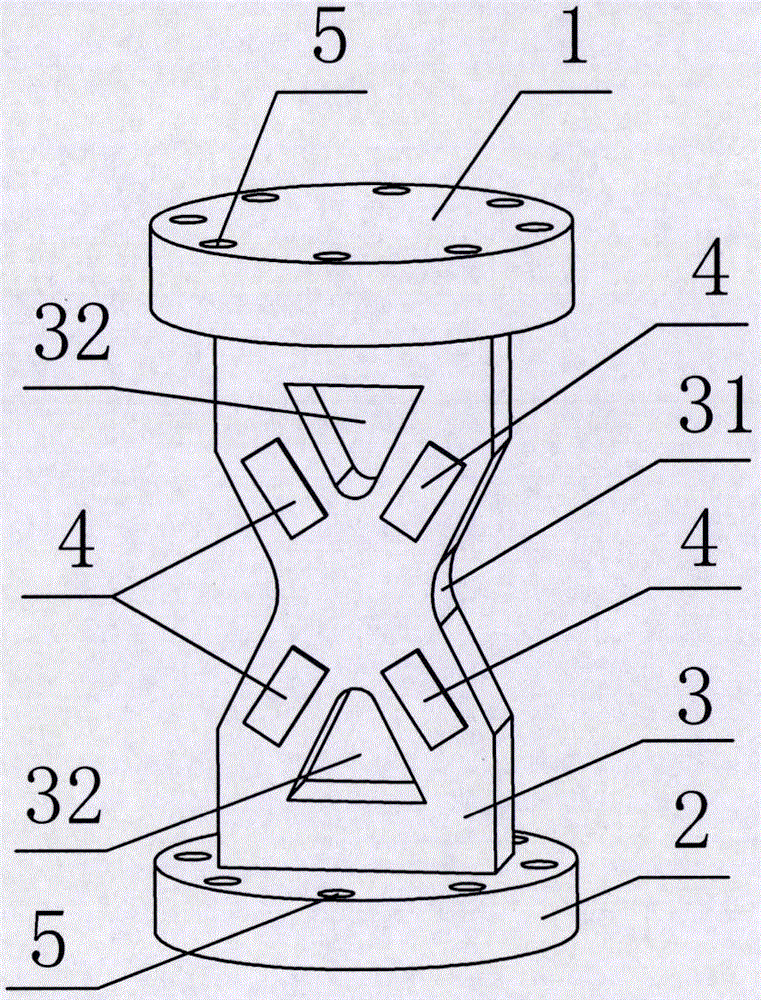

[0022] Such as figure 1 , 2 , 3, the thin-film strain type torque sensor of the present invention comprises a transfer upper flange 1, a transfer lower flange 2, and is affixed between the transfer upper flange 1 and the transfer lower flange 2. The torsion column consists of 3 components.

[0023] The torsion column 3 is a flat column processed from a metal material. In order to increase the sensitivity of the sensor, arc-shaped grooves 31 are processed on the left and right sides of the torsion column 3, and triangular holes 32 are processed on the upper and lower parts respectively. The size of the arc groove 31 and the triangular hole 32 depends on the measuring range of the sensor.

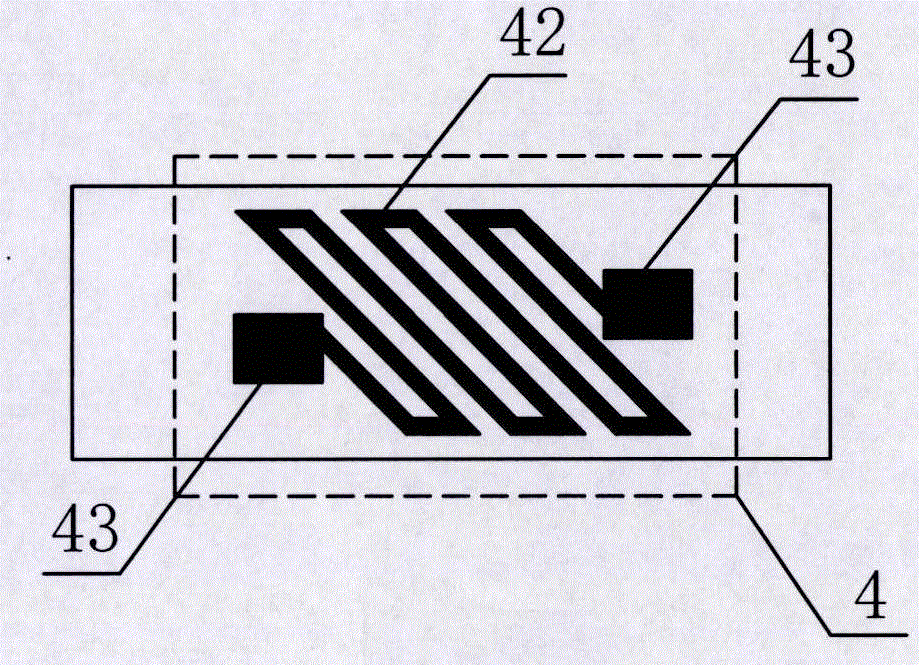

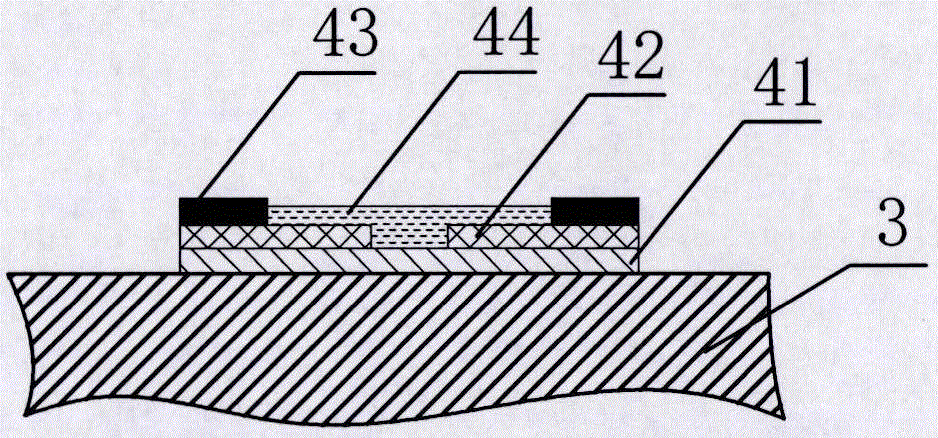

[0024] Four thin-film sensitive elements 4 are fabricated on one plane of the torsion column 3 by sputtering thin-film technology. The manufacturing method is to grind and polish the parallel surface of the torsion column 3 that needs to manufacture the thin-film sensitive element 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com