Valve testing stand for hydraulic support

A technology of hydraulic support and test bench, applied in the field of machinery, can solve the problems such as no emulsion valve found yet, and achieve the effect of high cost performance, high promotion value and broad market prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

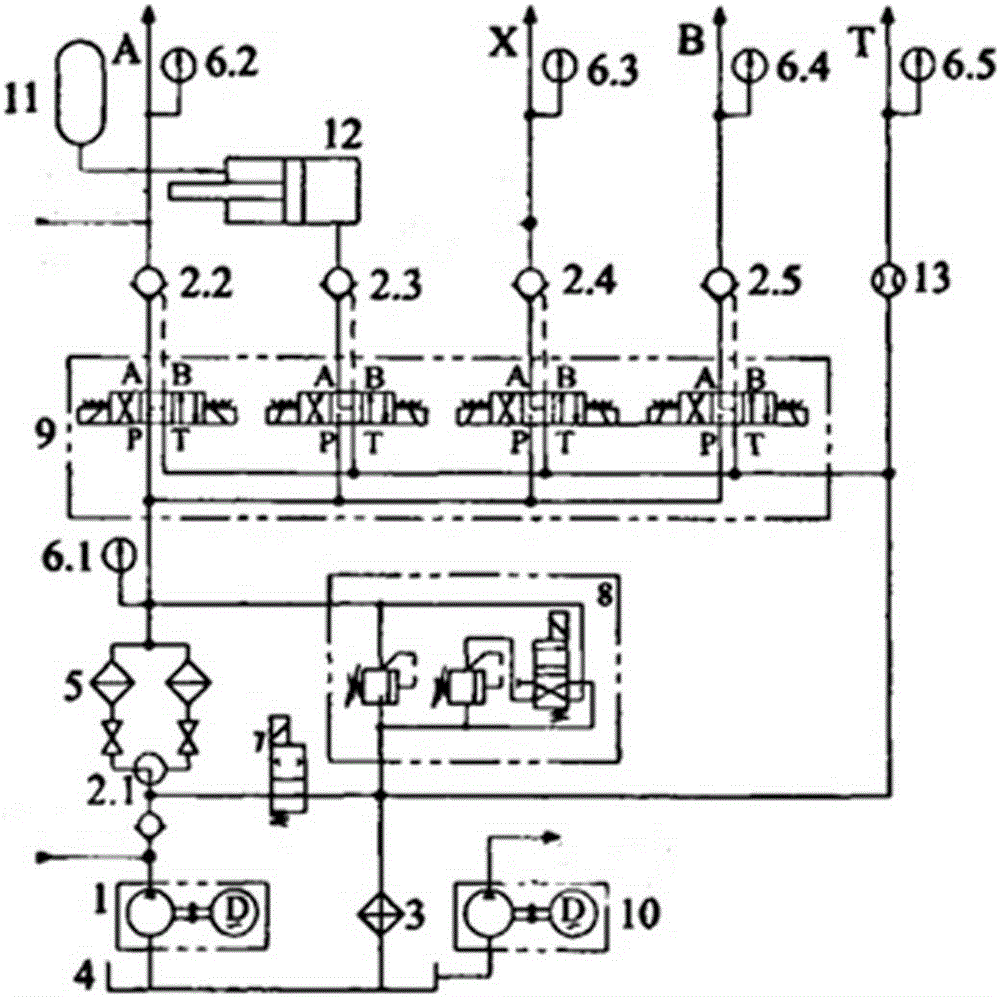

[0019] Such as figure 1 , The test bench test circuit adopts a new type of plunger motor pump unit 1, which is small in size, small in pressure pulsation and low in noise. Cooperating with the supercharger 12, it can meet the pressure and flow requirements of most tests. When a large test flow rate is required, the existing high-flow emulsion pump source is externally connected. Equipped with a suction pump l0, the emulsion in the water tank 4 of this station is sent to the large flow pump source water tank. The liquid suction pump can also be used as the circulating pump of the water tank for cooling and filtering.

[0020] The test bench provides four liquid ports A, B, T, and X, which are respectively connected to the liquid inlet, liquid outlet and control port of the test piece. The electro-hydraulic reversing valve 9 cooperates with the hydraulic control check...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com