Bottom mud sampling robot

A robot and sediment technology, applied in the field of robots, can solve the problems of not being able to record the position of the collected samples, the degree of automation is not high, and the sampling effect is not good, so as to achieve the effects of convenient and fast sampling, improved safety, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

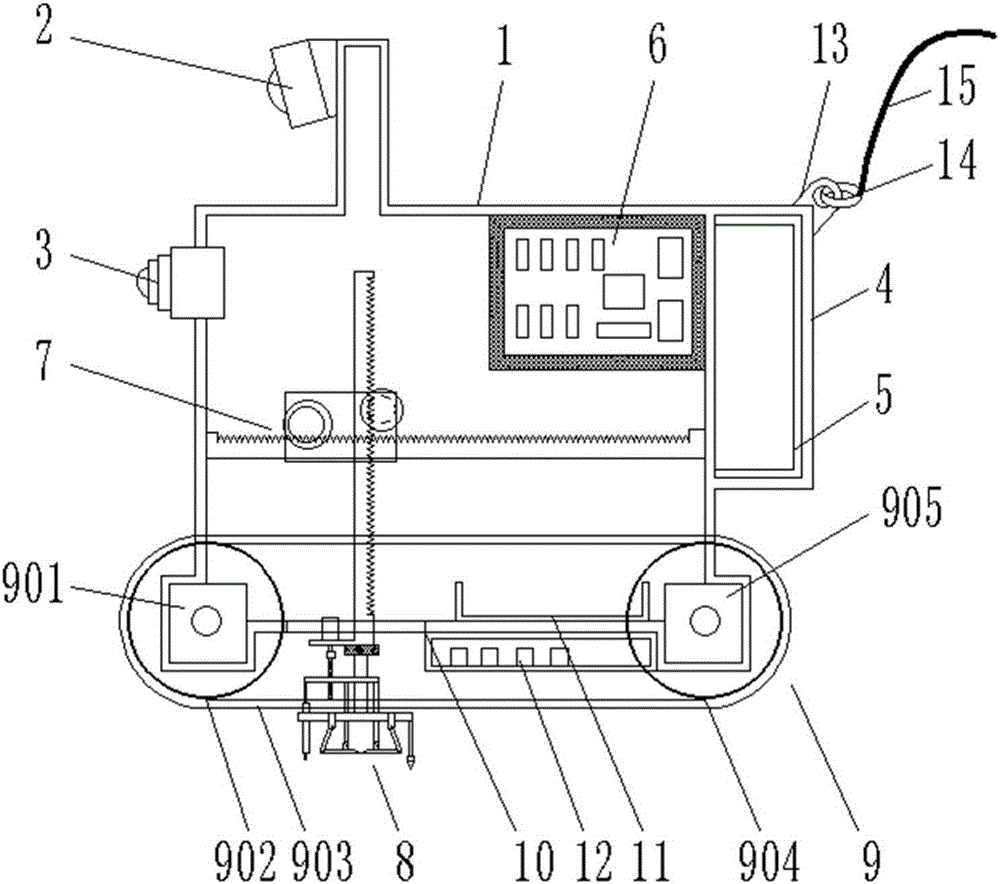

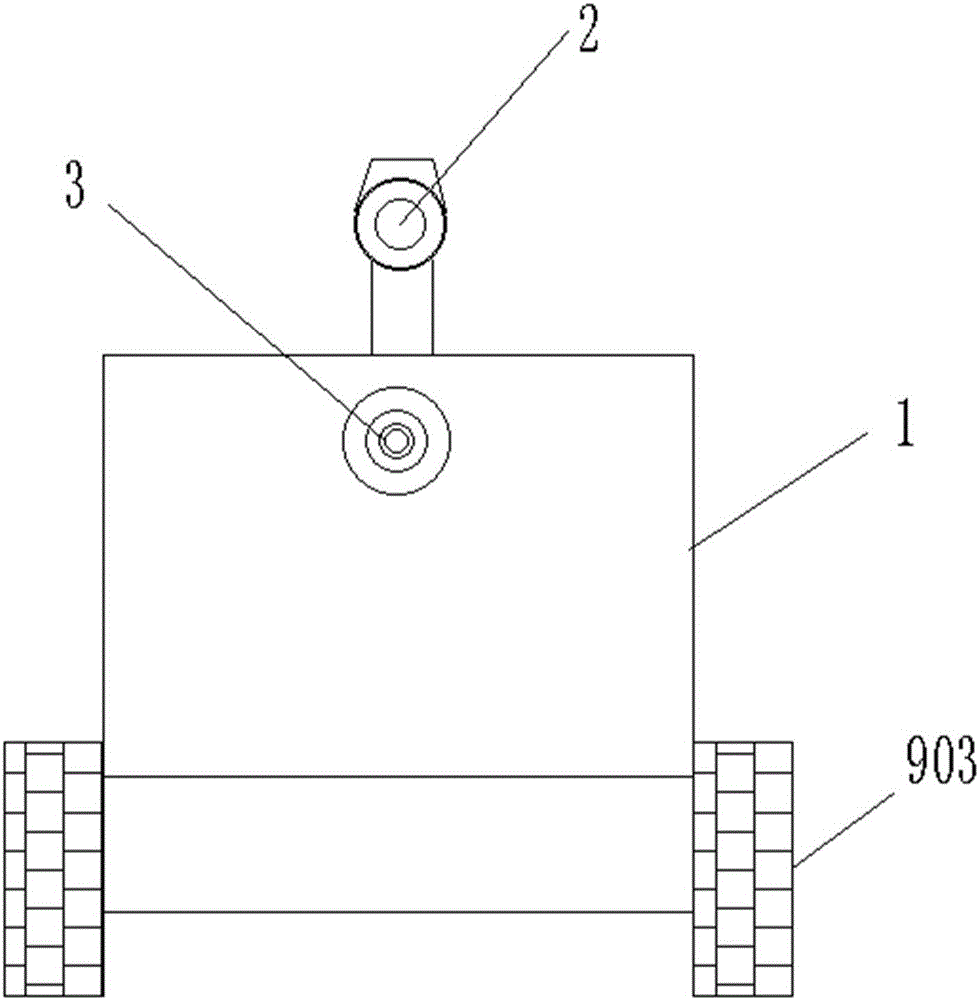

[0026] see figure 1 , in an embodiment of the present invention, a bottom mud sampling robot includes a housing 1, an illuminating lamp 2, a rotating camera 3, a battery sealing cover 4, a lithium battery 5, a control module 6, a truss module 7, a sampling detection module 8, and a drive module 9. Sampling port 10, sample loading box 11, weight adjustment module 12, traction seat 13, traction ring 14 and traction rope 15, an illuminating lamp 2 is installed above the casing 1, and a rotating shaft is installed above the front surface of the casing 1. Camera 3, the rear end surface of the rotating camera 3 is provided with a battery sealing cover 4, and a lithium battery 5 is installed inside the battery sealing cover 4;

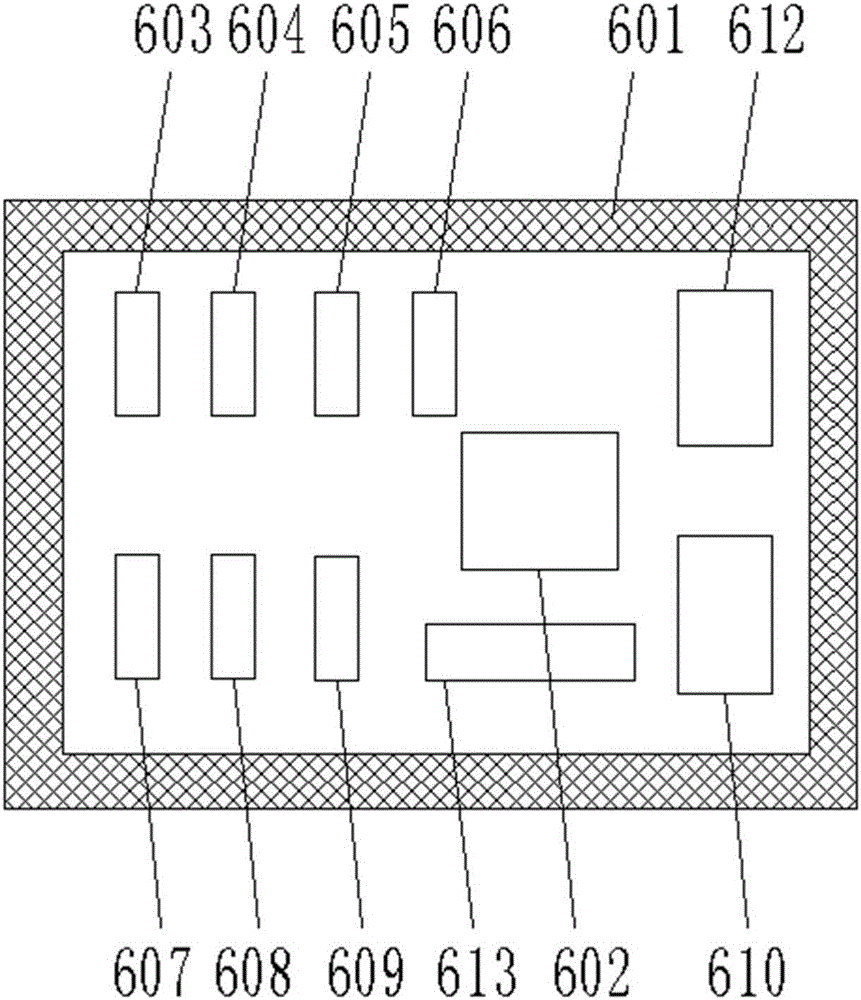

[0027] A control module 6 is installed on the left end surface inside the housing 1, and the control module 6 includes a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com