Spot welding detection device and spot welding detection method for nickel sheets of fuses

A technology for detecting devices and fuses, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unsuitable nickel sheet solder joint detection for fuses, inconvenient data checking and proofreading, and unrecordable test data, etc. Detection cost, uniform strength, and the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

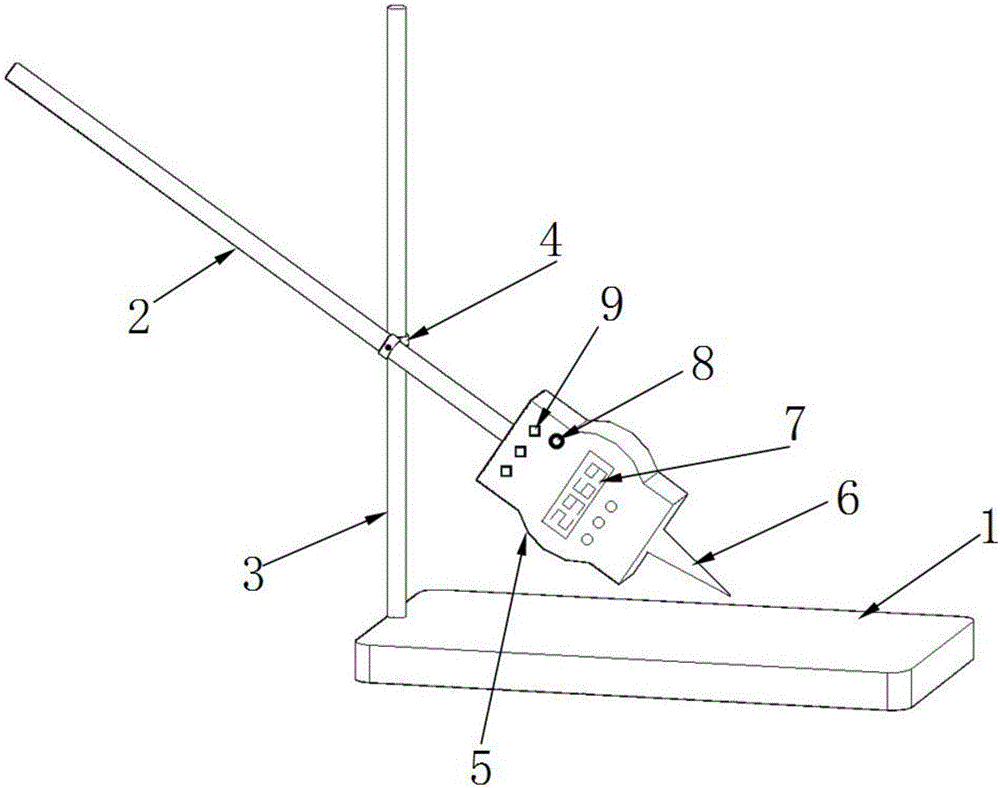

[0029] A fuse nickel sheet spot welding detection device, including a cross bar, a workbench, a support rod, a strength gauge and a hinge, wherein the support rod 3 is vertically fixed on the base surface of the workbench 1, and the cross bar 2 is connected to the support rod 3 through the hinge 4 Cross-connected, and the crossbar 2 rotates at the center of the hinge 4, and one end of the crossbar 2 is connected to one end of the dynamic gauge 5; the dynamic gauge 5 is provided with a detection and control system.

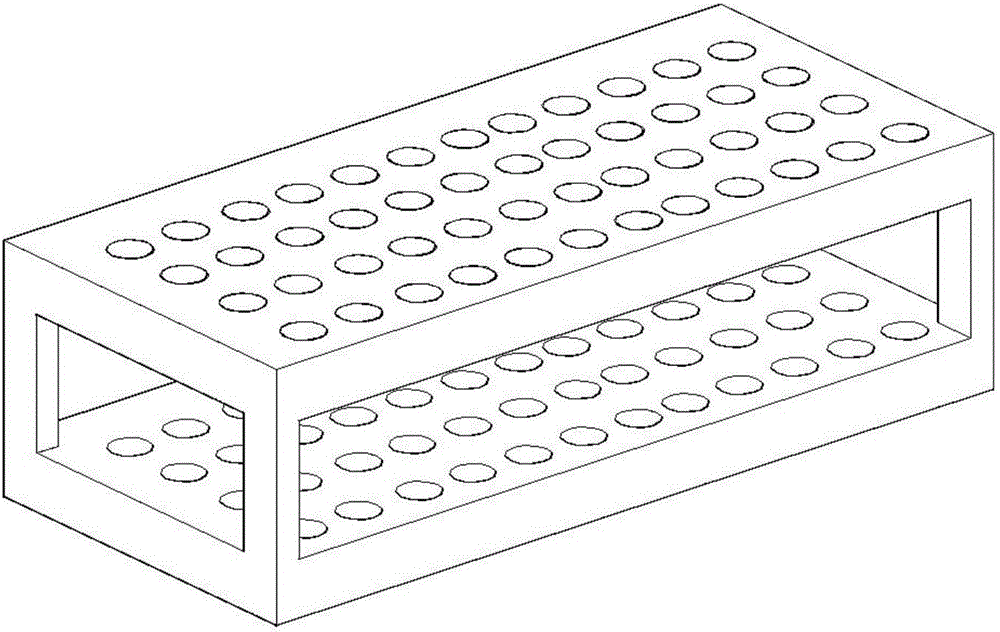

[0030] Among them, a nickel spot welding detection device for a fuse also includes a jig, the jig is in the shape of a cuboid, and the upper surface of the jig is uniformly provided with a number of holes, and the holes match the outline of the fuse to be tested; the jig can fix the fuse to be tested, which is convenient Inspection of solder joints.

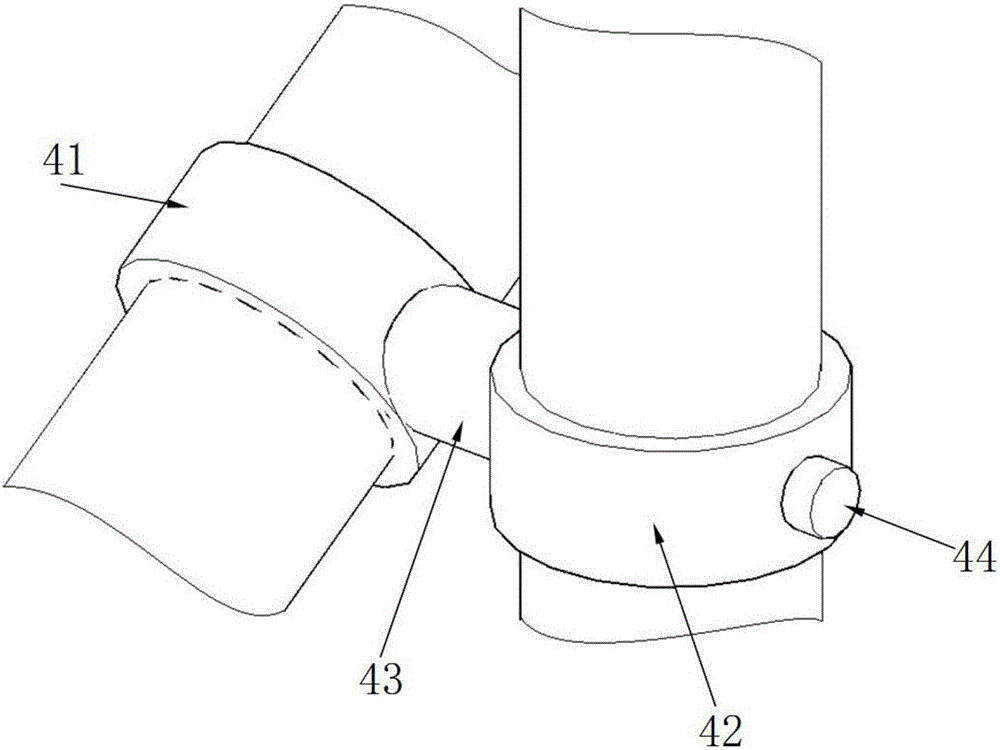

[0031] Wherein, the hinge 4 comprises a first rotating ring 41, a second rotating ring 42 and a rotating shaft 43, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com