Method for detecting consistency of single battery in storage battery

A single cell, battery pack technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of changes, only focus on the consistency of the previous single battery, and ignore the consistency of the battery, etc., to achieve consistency performance guarantee, fast data processing, and improved consistency problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the following, the present invention will be further described in conjunction with the description of the quality inspection of the 48V storage battery module.

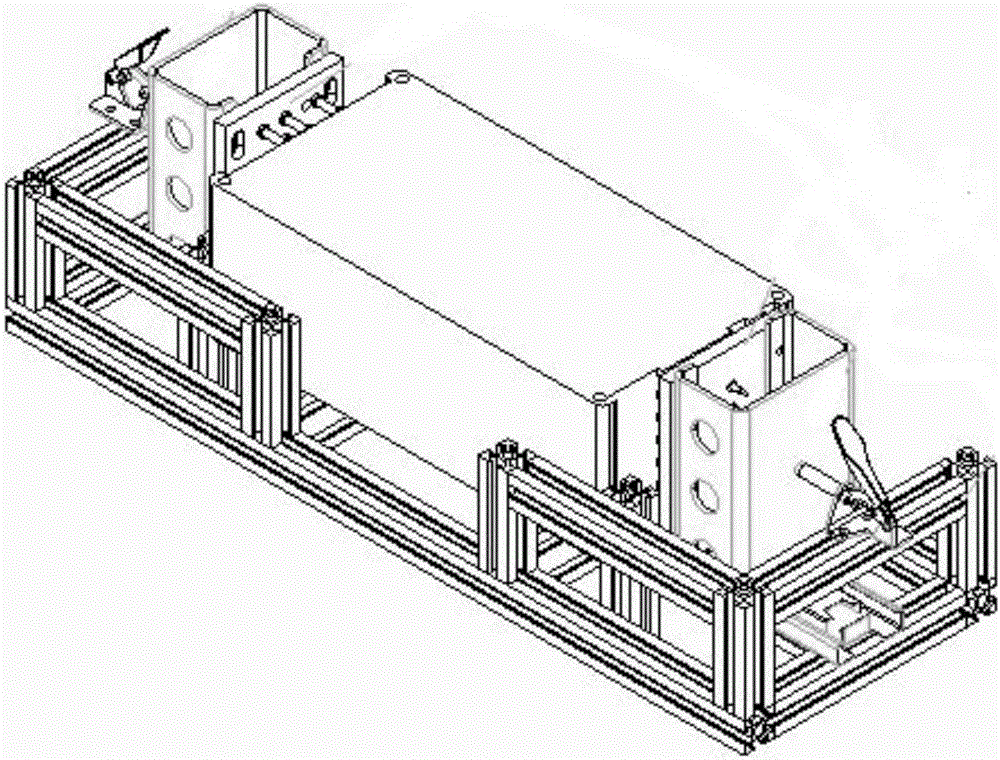

[0049] A 48V battery system used in the start-stop system of automobiles. The intermediate product 48V battery module in the production process is composed of 13 single power batteries connected in series by laser welding. The 48V battery module testing equipment has the functions of collecting single batteries and performing consistency analysis and judgment. The testing fixtures are as follows: figure 1 shown.

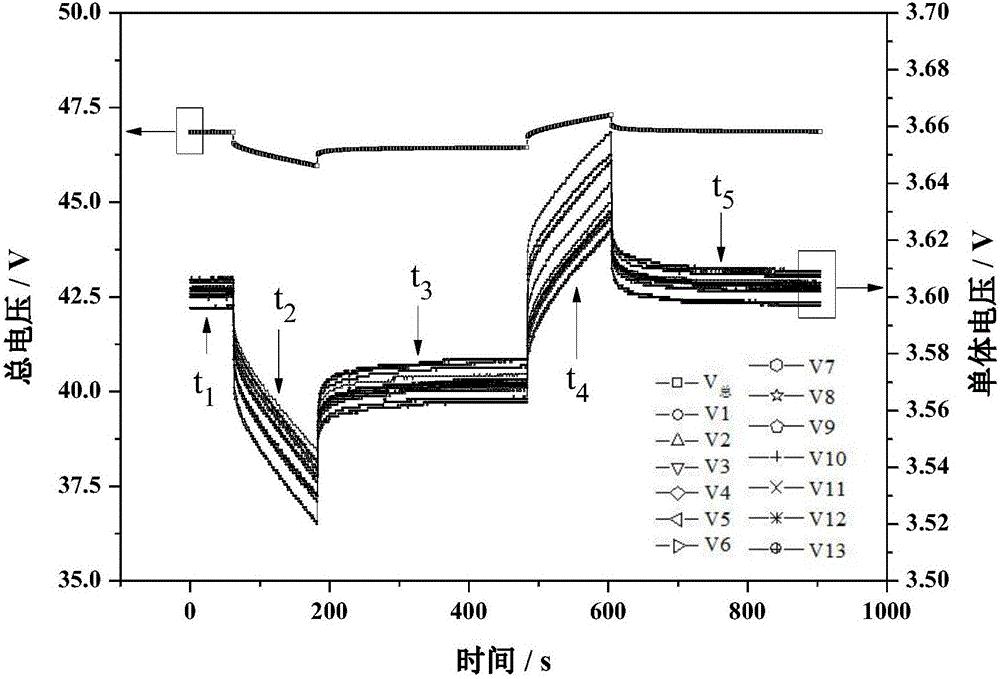

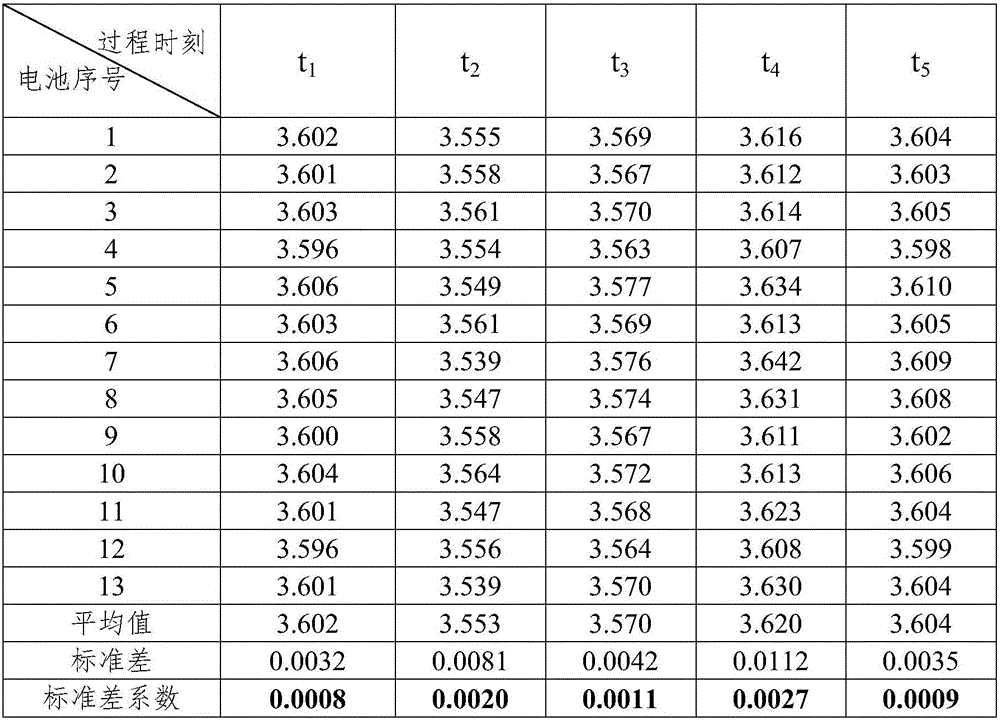

[0050] The battery modules connected in parallel are regarded as a single battery. There are 7 connectors at one end of the module and 7 connectors at the other end. After connecting with the charging and discharging instrument, 13 sets of voltage curves can be measured, such as figure 2. The original picture is in color, showing the voltage curves (V1...~V13) of each single battery and the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com