Broad-band high-diffraction-efficiency asymmetric morphology reflection grating

A diffraction-efficient, asymmetric technology, applied in the directions of diffraction gratings, optics, optical components, etc., to achieve the effect of simple grating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

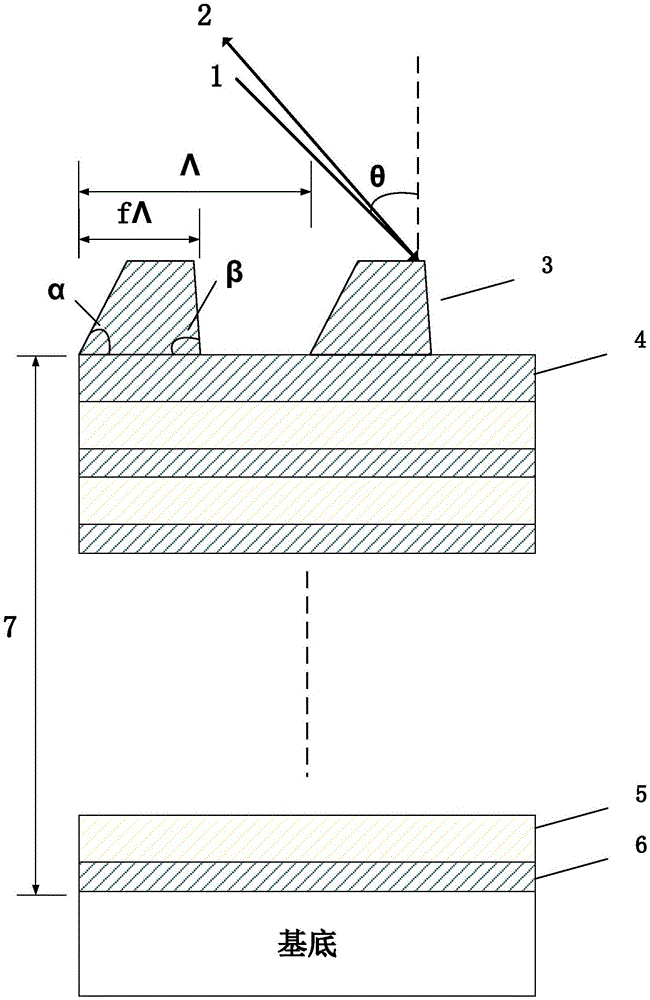

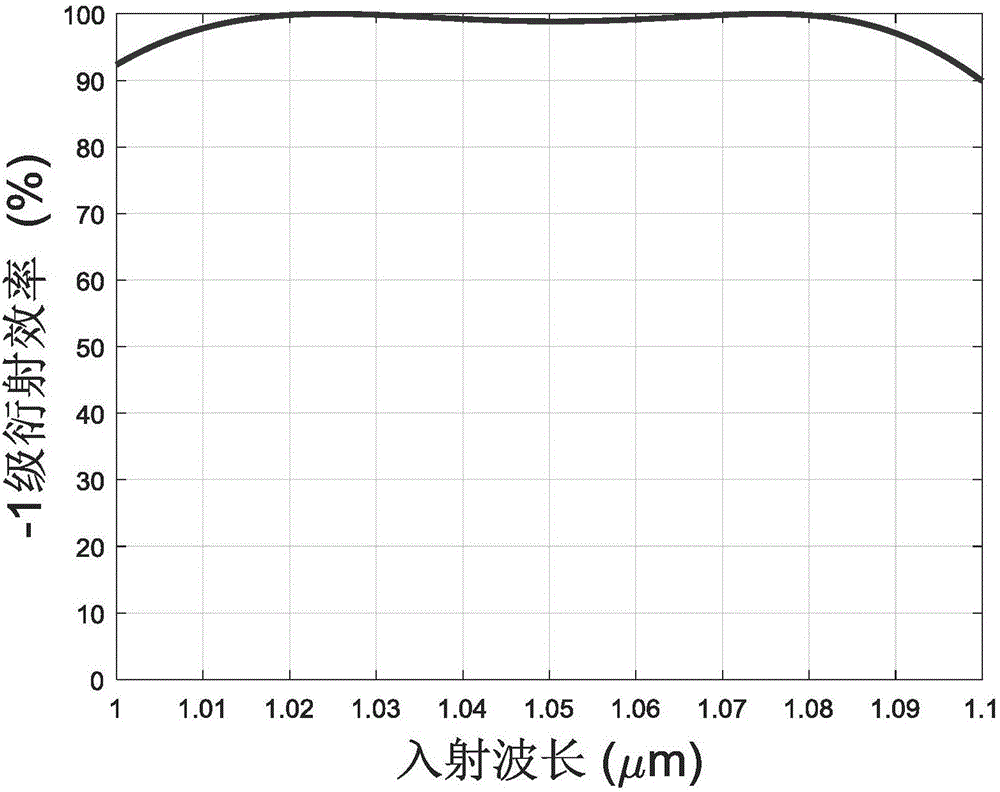

[0029] Broadband high diffraction efficiency asymmetric topography reflective gratings, such as figure 1 As shown, the grating consists of a top grating ridge structure 3, a middle high-reflectivity film layer 7 and a bottom substrate. The top grating ridge structure has an asymmetric shape, and the corresponding bottom angles α and β are 68° and 89°. The film structure of the grating is S|(HL) 15 RG|A, where S represents the substrate, H represents the high refractive index film layer 6 (Ta 2 o 5 ), L represents the low refractive index film layer 5 (SiO 2 ), the film period is 15 periods, and R represents the remaining dielectric layer of the grating with a thickness of 256 nm (HfO 2 ), G represents the grating ridge structure layer with a height of 400 nm (HfO 2 ), A means air. The period of the grating is 833 nanometers, the corresponding grating line density is 1200 lines per millimeter, and the bottom occupation ratio f is 0.66. Such as image 3 As shown, when th...

Embodiment 2

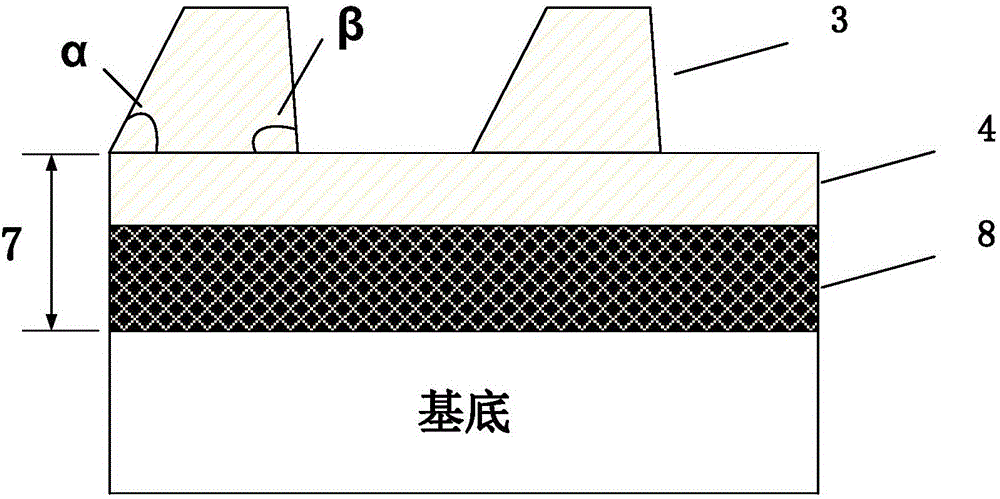

[0031] Broadband high diffraction efficiency asymmetric topography reflective gratings, such as figure 2 As shown, the grating structure is composed of the top grating ridge structure 3, the middle high-reflectivity film layer 7 and the bottom substrate, wherein the top grating ridge structure has an asymmetric shape, and the corresponding base angles α and β are 68° and 89° respectively . The film structure of the grating is S|MRG|A, where S represents the substrate, M represents the high-reflectivity metal layer (Au) with a thickness of 200 nm, and R represents the remaining dielectric layer (HfO) with a thickness of 168 nm. 2 ), G represents the grating ridge structure layer with a height of 567 nm (HfO 2 ), A means air. The period of the grating is 683 nanometers, the corresponding grating line density is 1464 lines per millimeter, and the grating duty ratio is 0.6. Such as Figure 5 It is shown that when the incident light is incident at the Littrow angle, in the ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com