Display panel and its manufacturing method and display device

A display panel and manufacturing method technology, applied in the direction of instruments, coatings, optics, etc., can solve problems such as abnormal display, poor waterproof performance, and affecting the performance of liquid crystal displays, and achieve the effect of improving waterproof performance and improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

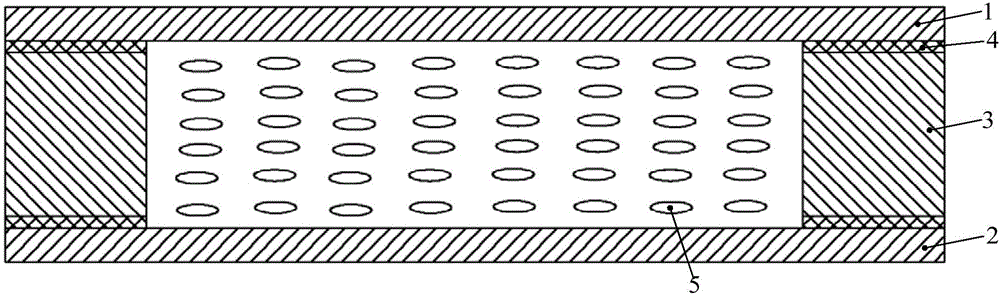

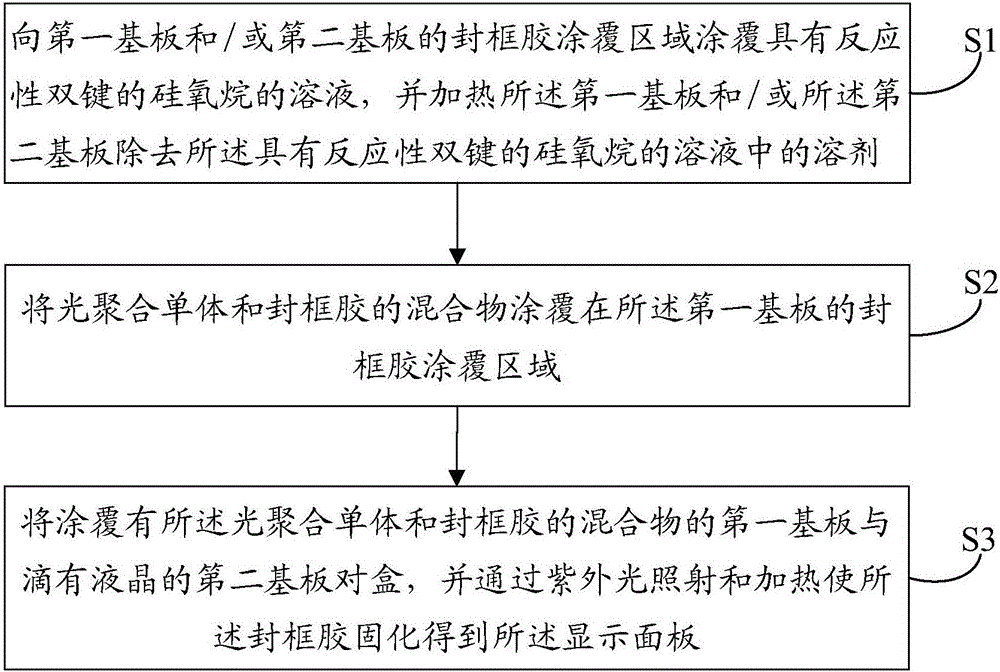

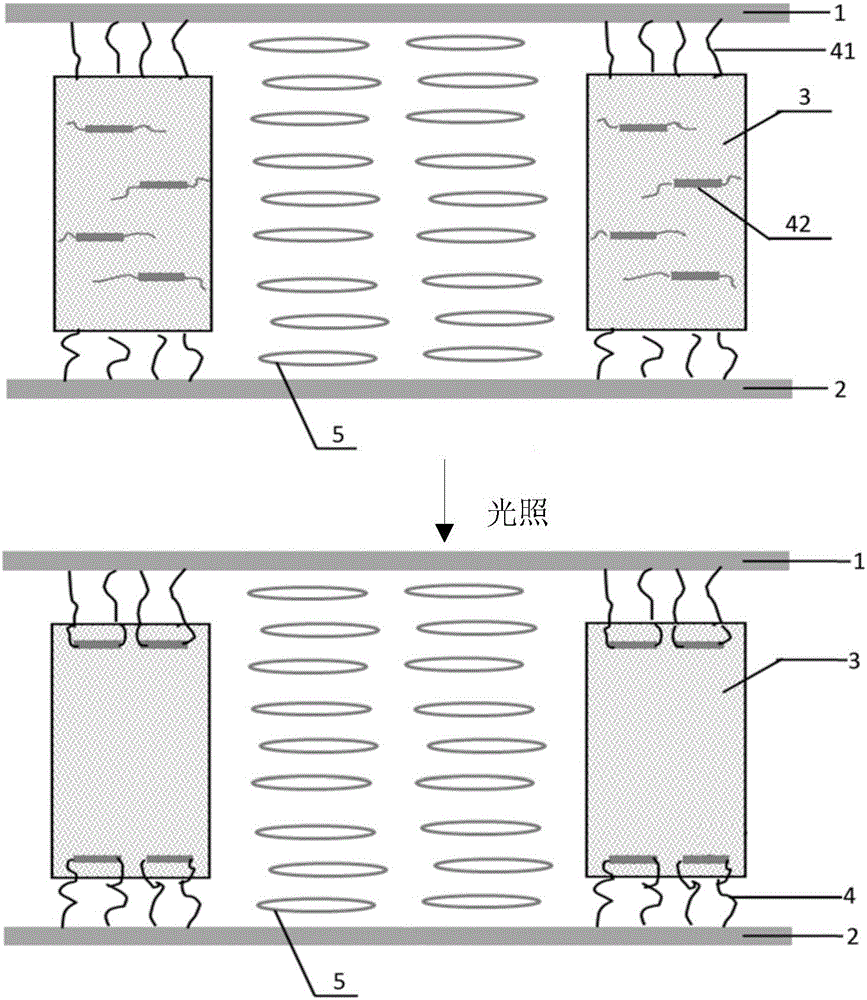

[0099] This embodiment provides a display panel and a manufacturing method thereof, and the manufacturing method specifically includes:

[0100] Step 101, dissolving siloxane with reactive double bonds having the structure shown in formula (II) in distilled water to obtain an aqueous solution of siloxane with reactive double bonds, wherein the siloxane with reactive double bonds The mass percentage of alkane is 2%.

[0101] Step 102 , coating the siloxane aqueous solution obtained in step 101 on the sealant coated areas of the first substrate and the second substrate, and then heating the first substrate and the second substrate at 100° C. for 1 hour.

[0102]Step 103, mix the frame sealant SWB-73 (purchased from Sekisui Chemical Industry Co., Ltd.) and the photopolymerizable monomer having the structure shown in formula (IV) according to the mass ratio of 95:5 and put them into the defoaming The defoaming treatment was carried out in the container under the condition of avoi...

Embodiment 2

[0109] This embodiment provides a display panel and a manufacturing method thereof, and the manufacturing method specifically includes:

[0110] Step 201, dissolving siloxane with reactive double bonds having the structure shown in formula (II) in distilled water to obtain an aqueous solution of siloxane with reactive double bonds, wherein the siloxane with reactive double bonds The mass percentage of alkane is 3%.

[0111] Step 202 , coating the siloxane aqueous solution obtained in step 201 on the sealant coated areas of the first substrate and the second substrate, and then heating the first substrate and the second substrate at 100° C. for 1.5 hours.

[0112] Step 203, mix the frame sealant SUR-66 (purchased from Sekisui Chemical Industry Co., Ltd.) and the photopolymerizable monomer having the structure shown in formula (IV) according to the mass ratio of 97:3 and put them into the defoaming The defoaming treatment was carried out in the container under the condition of ...

Embodiment 3

[0118] This embodiment provides a display panel and its manufacturing method, wherein the manufacturing method differs from Embodiment 1 in that:

[0119] The mass percentage of siloxane with reactive double bonds is 1%;

[0120] After coating the siloxane aqueous solution on the sealant-coated areas of the first substrate and the second substrate, heating the first substrate and the second substrate at 100° C. for 2 hours;

[0121] In the mixture of the frame sealant and the photopolymerizable monomer, the mass ratio of the frame sealant to the photopolymerizable monomer is 97:3.

[0122] According to the test method of Example 1, the high-temperature and high-humidity reliability test of the display panel obtained in this example is carried out, and the test results are the same as those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com