Cerium rare earth permanent magnet material and preparation method thereof

A rare-earth permanent magnet and rare-earth permanent magnet technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of reducing material costs, improve product competitiveness, increase the proportion of addition, and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

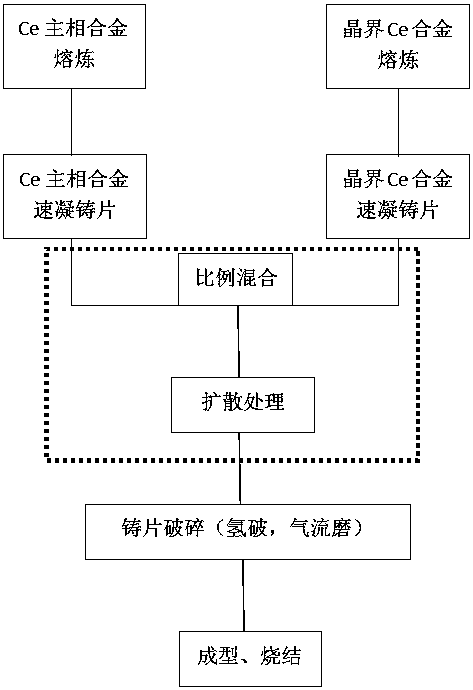

Image

Examples

Embodiment 1

[0021] 1) Alloy composition

[0022] Ce main phase alloy composition is Nd 28.5 co 1.0 Al 0.2 B 1.05 Fe 余量 ;

[0023] Grain boundary Ce alloy composition: Ce 70 Fe 20 co 5 Cu 5 ;

[0024] Composition control: the method of directly adding an appropriate amount of Ce to the main phase combined with the addition of Ce at the grain boundary, the direct addition of the main phase is: (Ce x Re 1-x ) y co 0.5 Cu 0.2 Al 0.4 Fe 余量 B 0.95 (wt%), wherein Re is a rare earth element containing at least Nd, and Ce is added directly in the main phase, which inevitably enters the main phase and causes a significant drop in magnetic properties, so it is necessary to control the amount of addition, 0≤x≤15wt%, while ensuring that the main The phase ratio is as high as possible, and y needs to be close to the main phase composition, so 28.5wt%≤y≤30.5wt%, the Ce alloy composition added to the grain boundary is Ce z Fe 余量 m 15 (wt%), 50wt%≤z≤70wt%, M is added Cu, Co, Al metal e...

Embodiment 2

[0040] 1) Alloy composition

[0041] Ce main phase alloy composition (Ce 10 Nd 90 ) 30.5 co 1.0 Cu 0.2 al 0.4 B 1.05 Fe 余量 ;

[0042] Grain Boundary Ce Alloy Composition Ce 50 Fe 35 co 5 Cu 4 al 6 ;

[0043] 2) Quick-setting cast sheet

[0044] Ce main phase alloy (Ce 10 Nd 90 ) 30.5 co 1.0 Cu 0.2 al 0.4 B 1.05 Fe 余量 The quick-setting process is adopted, and the casting temperature according to the addition ratio of Ce is: 1425°C;

[0045] Grain Boundary Ce Alloy Ce 50 Fe 35 co 5 Cu 4 al 6 Smelting and quick-setting cast pieces;

[0046] 3) Diffusion treatment

[0047] Ce main phase alloy according to (Ce 10 Nd 90 ) 30.5 co 1.0 Cu 0.2 al 0.4 B 1.05 Fe 余量 and grain boundary Ce alloy Ce 50 Fe 35 co 5 Cu 4 al 6 , mixed at a ratio of 95:5, the mixed alloy was diffused at 800°C for 10 hours, and the vacuum degree of diffusion treatment was controlled at 2*10 -2 Pa;

[0048] 4) Pulverization, orientation molding

[0049] After the diffusi...

Embodiment 3

[0055] 1) Alloy composition

[0056] Ce main phase alloy composition (Ce 15 Nd 85 ) 29 co 0.5 al 0.2 Cu 0.1 B 1.0 Fe 余量 ;

[0057] Grain Boundary Ce Alloy Composition Ce 50 Fe 35 co 5 Cu 4 al 6

[0058] 2) Quick-setting cast sheet

[0059] Ce main phase alloy (Ce 15 Nd 85 ) 29 co 0.5 al 0.2 Cu 0.1 B 1.0 Fe 余量 The quick-setting process is adopted, and the casting temperature according to the addition ratio of Ce is: 1410°C;

[0060] Grain Boundary Ce Alloy Ce 50 Fe 35 co 5 Cu 4 al 6 Melting, quick-setting casting

[0061] 3) Diffusion treatment

[0062] Ce main phase alloy (Ce 15 Nd 85 ) 29 co 0.5 al 0.2 Cu 0.1 B 1.0 Fe 余量 and grain boundary Ce alloy Ce 50 Fe 35 co 5 Cu 4 al 6 Mix according to the ratio of 90:10, the mixed alloy cast sheet is 4*10 -2 Diffusion treatment at 720°C for 12 hours under vacuum condition of Pa;

[0063] 4) Pulverization, orientation molding

[0064] After the above-mentioned alloy diffusion treatment, carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com