QLED and preparation method thereof

A derivative and graphene technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor electro-optic conversion efficiency of blue QLEDs and affect the efficiency of full-color display QLED devices, so as to improve the performance of QLED devices and improve Photoelectric conversion efficiency, effect of improving hole transport and electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

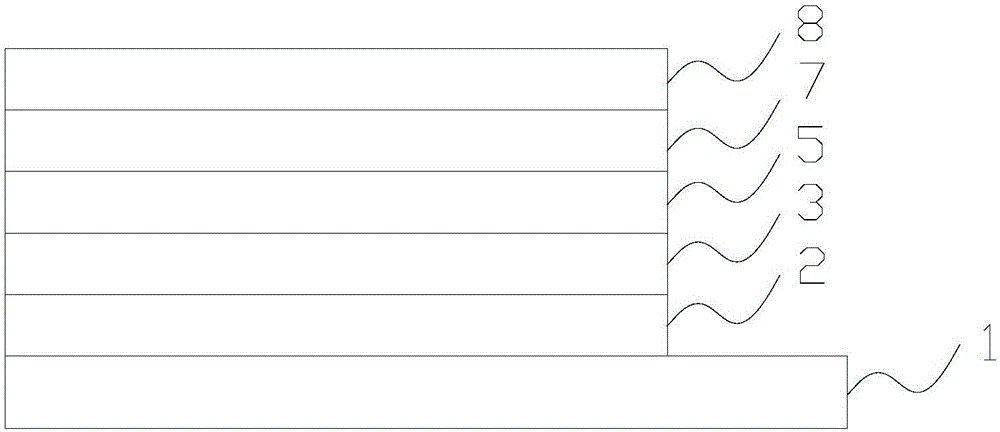

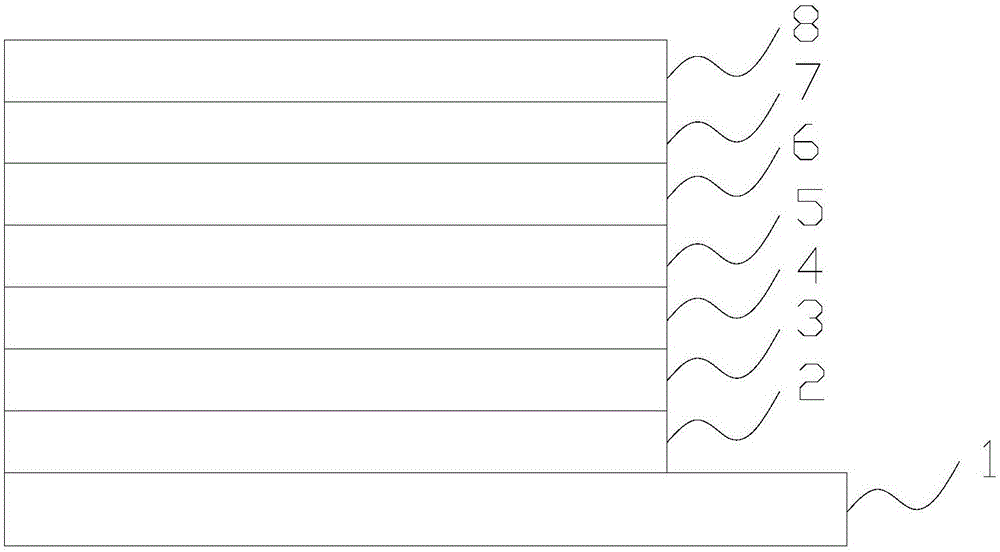

[0014] combine figure 1 , figure 2 , an embodiment of the present invention provides a QLED, including a substrate 1, an anode 2, a graphene oxide layer 3, a quantum dot light-emitting layer 5, a graphene oxide derivative layer 7, and a cathode 8 that are sequentially stacked, such as figure 1 As shown, wherein, the graphene oxide derivative layer 7 is made of graphene oxide derivatives, and the graphene oxide derivatives are graphene oxide in which carboxyl protons in graphene oxide are partially or completely replaced by metal elements derivative.

[0015] Specifically, in the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com