Battery temperature control system

A battery temperature and control system technology, applied in the direction of temperature control, control/regulation system, temperature control using electric methods, etc., can solve the problem of failure to respond in time, temperature sensor unable to cover the inside of the battery box battery, and temperature control equipment startup Hysteresis and other issues to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with embodiment.

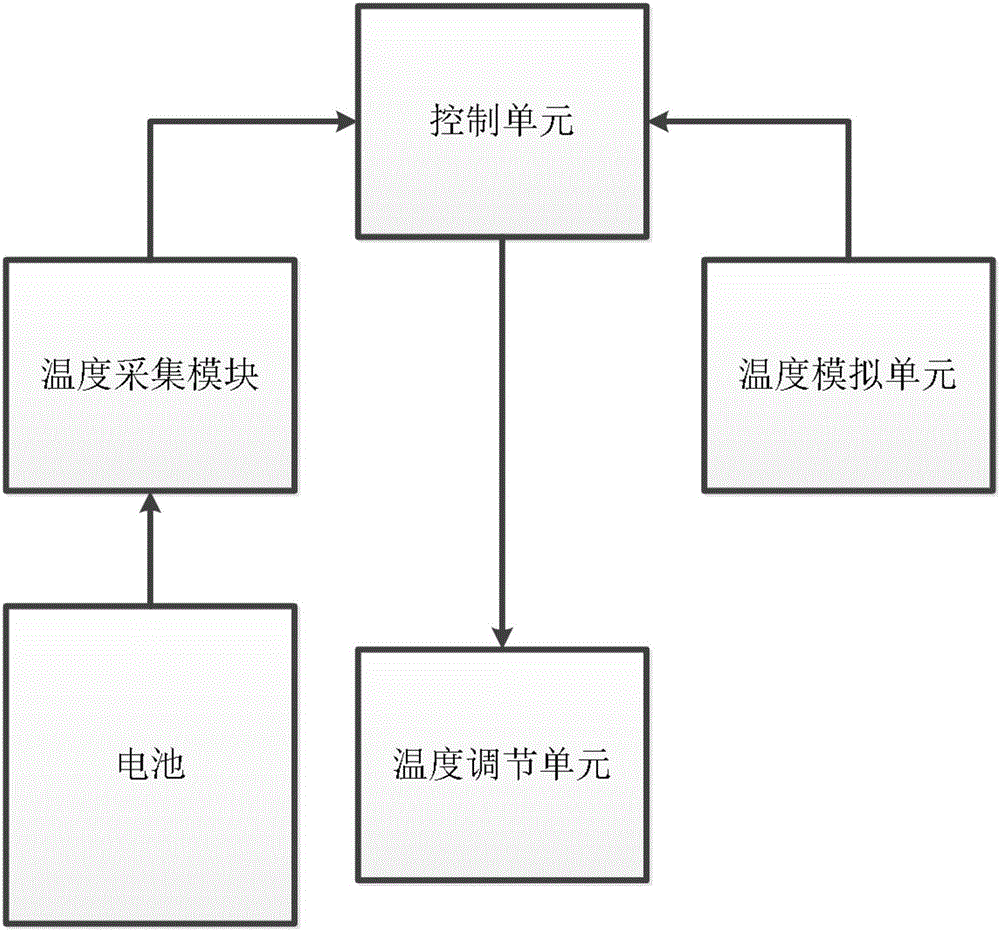

[0016] Invention-based embodiments such as figure 1 A battery temperature control system is shown, including a temperature acquisition unit, a temperature simulation unit, a control unit, and a temperature adjustment unit, wherein the temperature simulation unit outputs the predicted temperature of the battery based on the battery thermal model: the temperature acquisition unit is used to collect temperature distributed in the battery The actual temperature of several temperature measurement points; the control unit obtains the predicted temperature and the actual temperature, and outputs a temperature adjustment command based on the difference between the actual temperature and the predicted temperature to drive the temperature adjustment unit.

[0017] Attach a positive temperature coefficient thermistor (PTC) to the position of the positive and negative poles of the battery, collect the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com