Two-body-type welding structure of inner conductors of radio-frequency coaxial connector

A radio frequency coaxial, welded structure technology, applied in the direction of connection, conductive connection, welding/fusion connection, etc., can solve the problems of affecting performance, poor contact, ugly appearance of welding connection, etc., and achieves convenient operation, simple structure, reasonable and novel design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

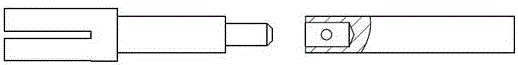

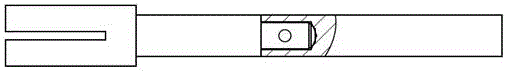

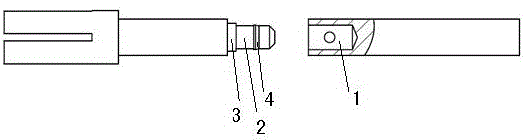

[0015] Such as Figure 1-5 As shown, the present invention is a two-piece welding structure for the inner conductor of a radio frequency coaxial connector. A socket 1 is provided in the first inner conductor, and a pin 2 that matches the socket 1 is provided on the second inner conductor. The first inner conductor and the second inner conductor are plugged and arranged, a step 3 is provided between the second inner conductor and the post 2, and the setting of the step 3 makes the two inner conductors connected to form one When designing the groove, the area of the groove should be equivalent to the cross-sectional area of the solder wire. To ensure that aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com