Asynchronous-starting permanent-magnet synchronous motor with inner rotor and outer rotor

A permanent magnet synchronous motor, asynchronous starting technology, applied in the direction of synchronous machine, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problems of low efficiency, inability to achieve energy saving, and low cost performance of the overall system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

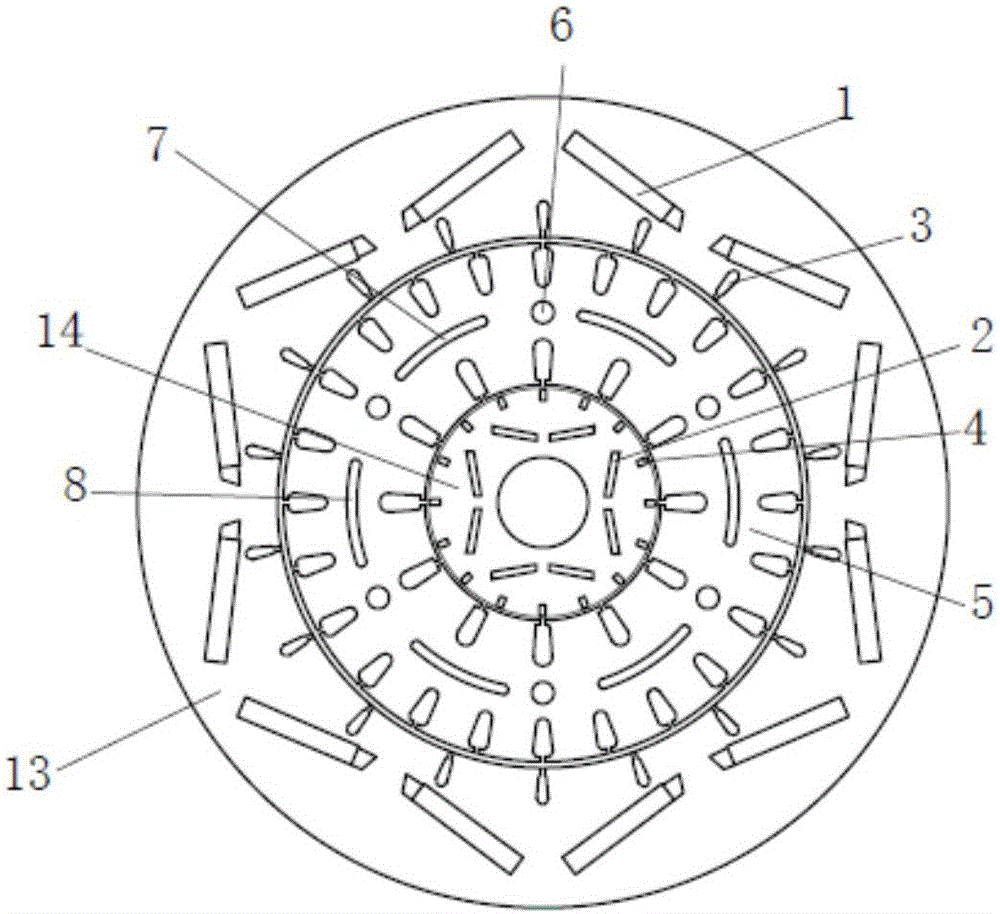

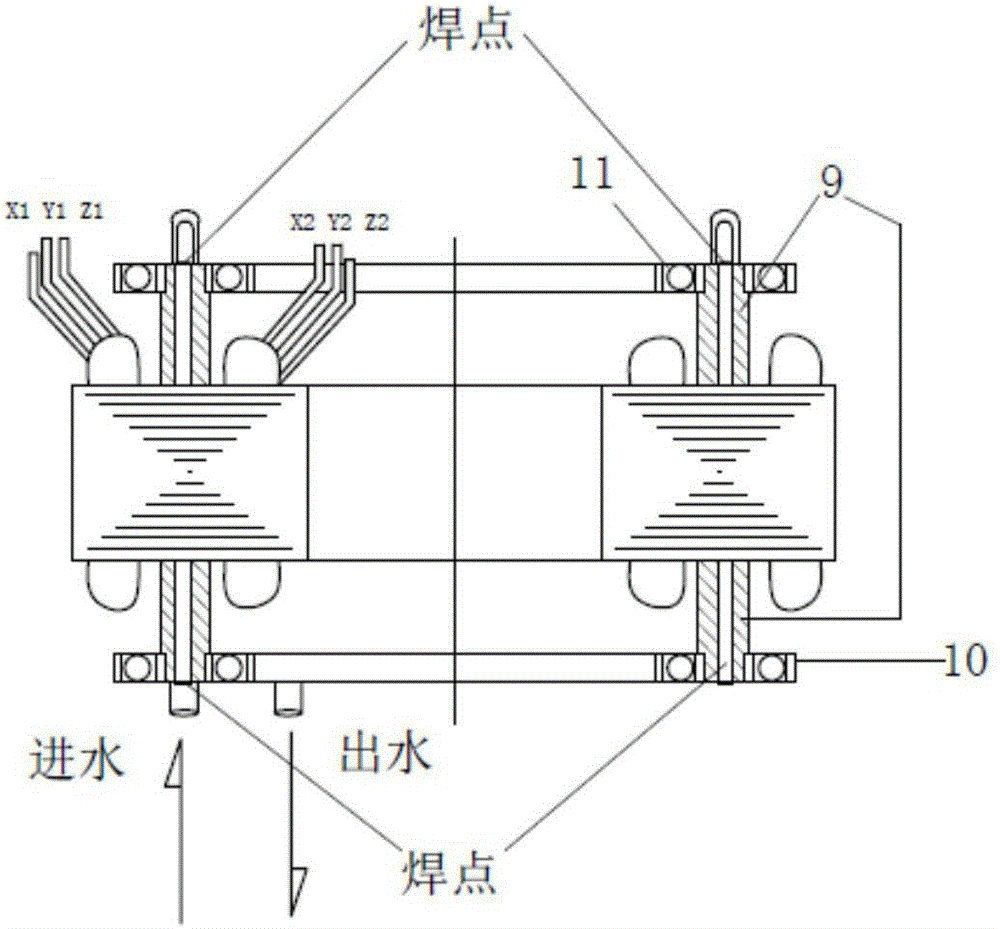

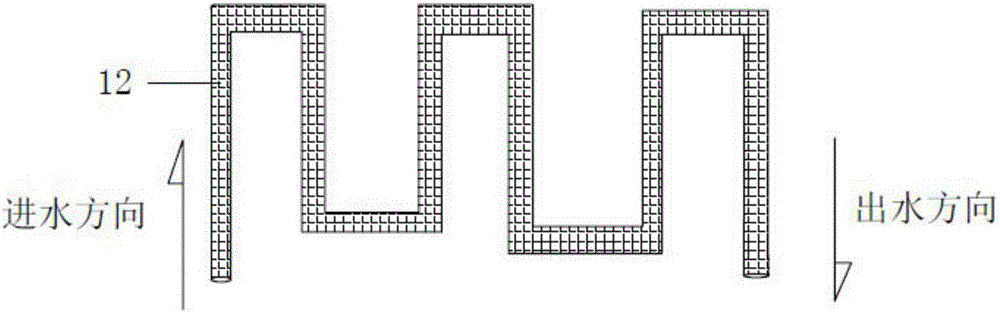

[0011] The present invention comprises an outer rotor 13, an inner rotor 14, a common stator 5, a connecting pin 6, a heat dissipation water pipe 12, and end support steel 9; Slot-embedded windings, with pin holes in the middle, cooling water pipe inlet hole 7 and cooling water pipe outlet hole 8; connecting pins 6 pass through the end support steel 9 in turn, and the common stator 5 is integrated with another end support 9 steel. The ends of the connecting pin 6 are welded together with the two end brace steels 9; the internal and external spigots of the car are based on the inner diameter of the common stator to ensure concentricity and the inner ring bearing 11 and the outer ring bearing 12 are installed to support the inner and outer rotors.

[0012] The outer rotor 13 is embedded with outer rotor magnetic steel 1, and the inner surface has outer rotor squirrel cage bars 3; the inner rotor is embedded with inner rotor magnetic steel 2, and the outer surface has inner rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com