Piezoelectric sensor

A piezoelectric sensor and piezoelectric induction technology, which is applied in the direction of instruments, electrical components, and electrical devices, can solve the problems of difficult battery replacement, battery recyclability, and end of service life of nodes, so as to reduce the cost of burying and avoid sensor Failure phenomenon, effect of improving reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

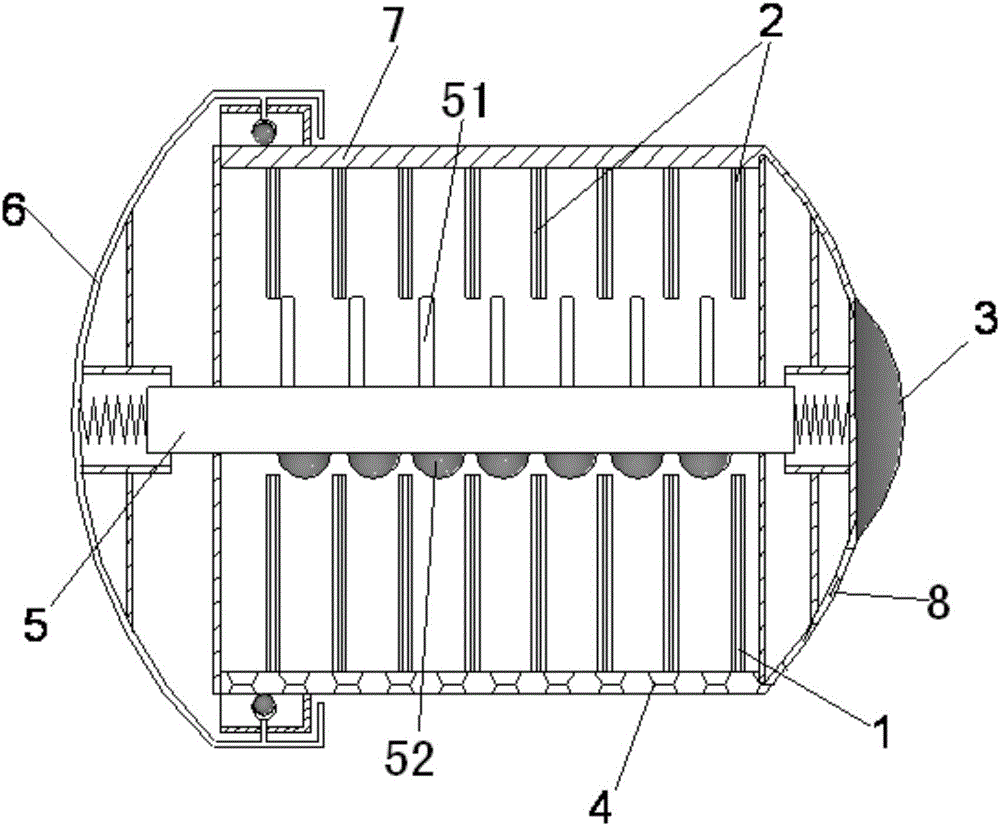

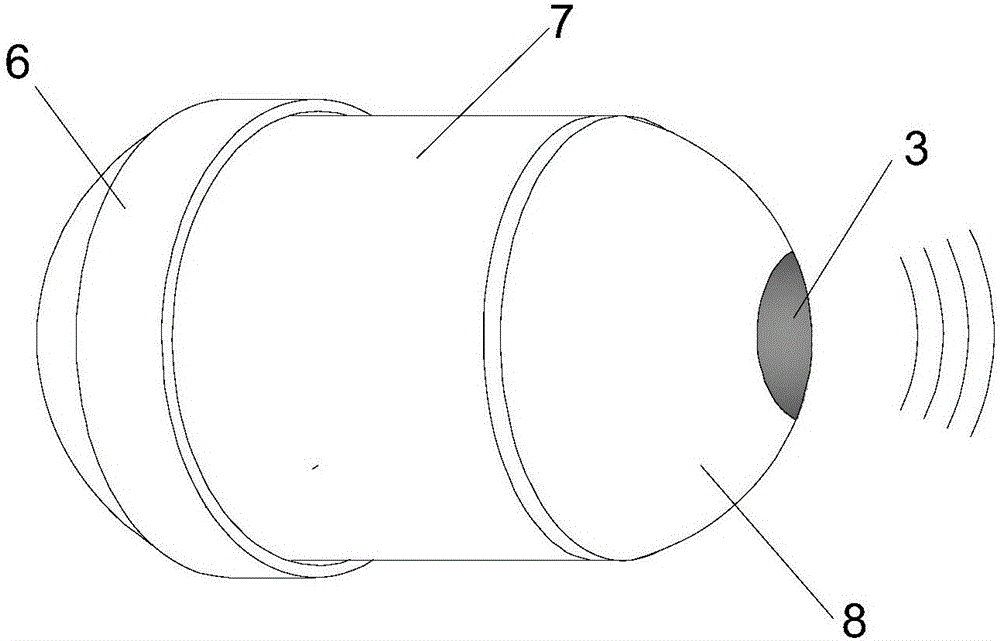

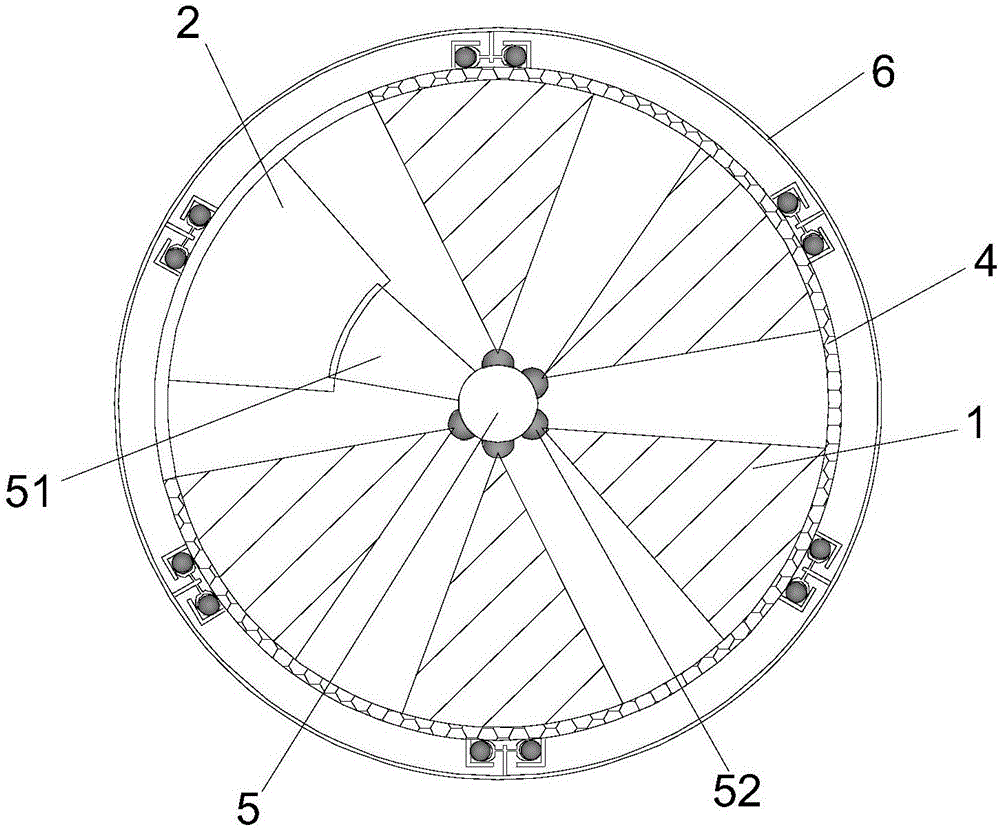

[0021] Such as figure 1 and figure 2 As shown, a pressure self-powered wireless sensor for monitoring the structural deformation of the underground powerhouse of a hydropower station has a cylindrical cavity 7 in the middle, and the two ends are covered with hemispherical shells (hemispherical shell B6, hemispherical shell A8) in different ways; It includes a piezoelectric energy collection module 1, a stress wave piezoelectric sensing module 2, a wireless signal transmitting module 3 and an integrated circuit module 4; the integrated circuit module 4 is arranged on the inner wall of a cylindrical cavity, and the wireless signal transmitting module 3 is set On the hemispherical shell A8.

[0022] Such as figure 1 , image 3 As shown, the piezoelectric energy harvesting module 1 and the stress wave piezoelectric sensing module 2 both adopt a piezoelectric cantilever struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com