Motor rotor automatic packaging and paper cutting device for motor rotor

An automatic packaging and motor rotor technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of low work efficiency, poor packaging effect, easy waste of materials, etc., to achieve convenient operation, high packaging efficiency and practicality sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

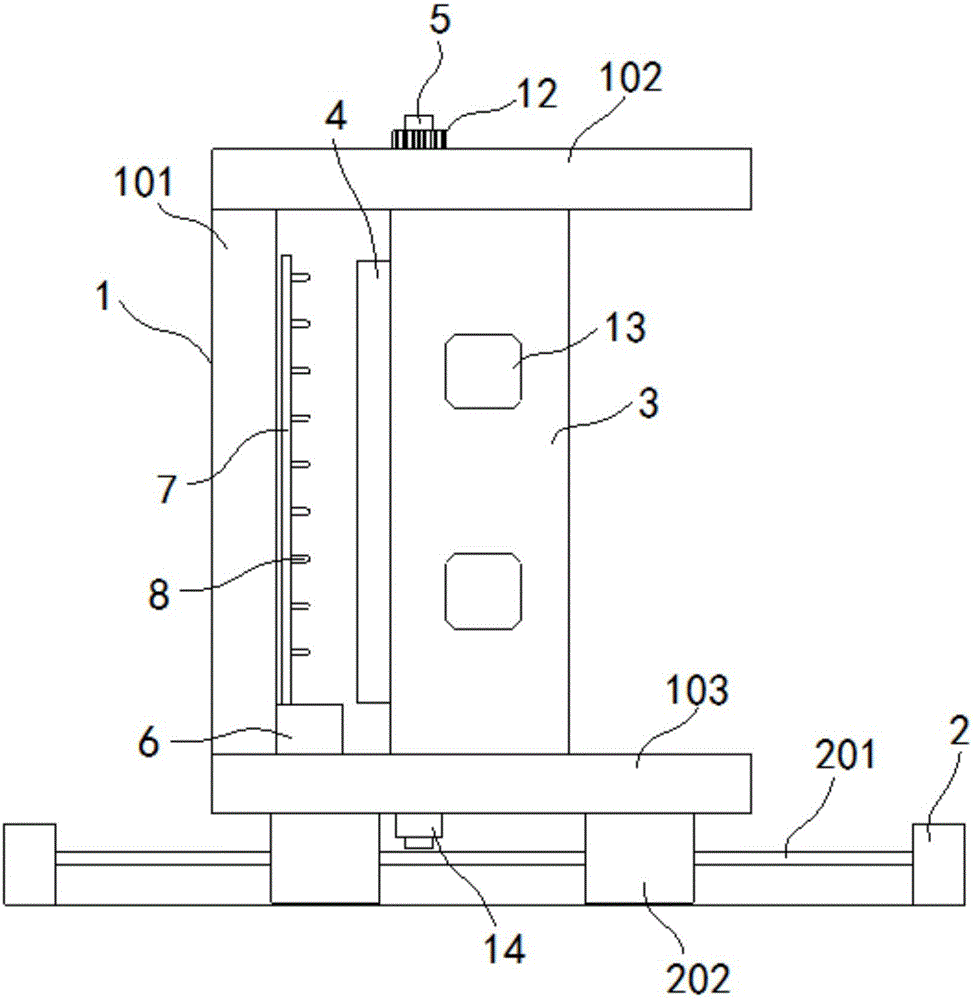

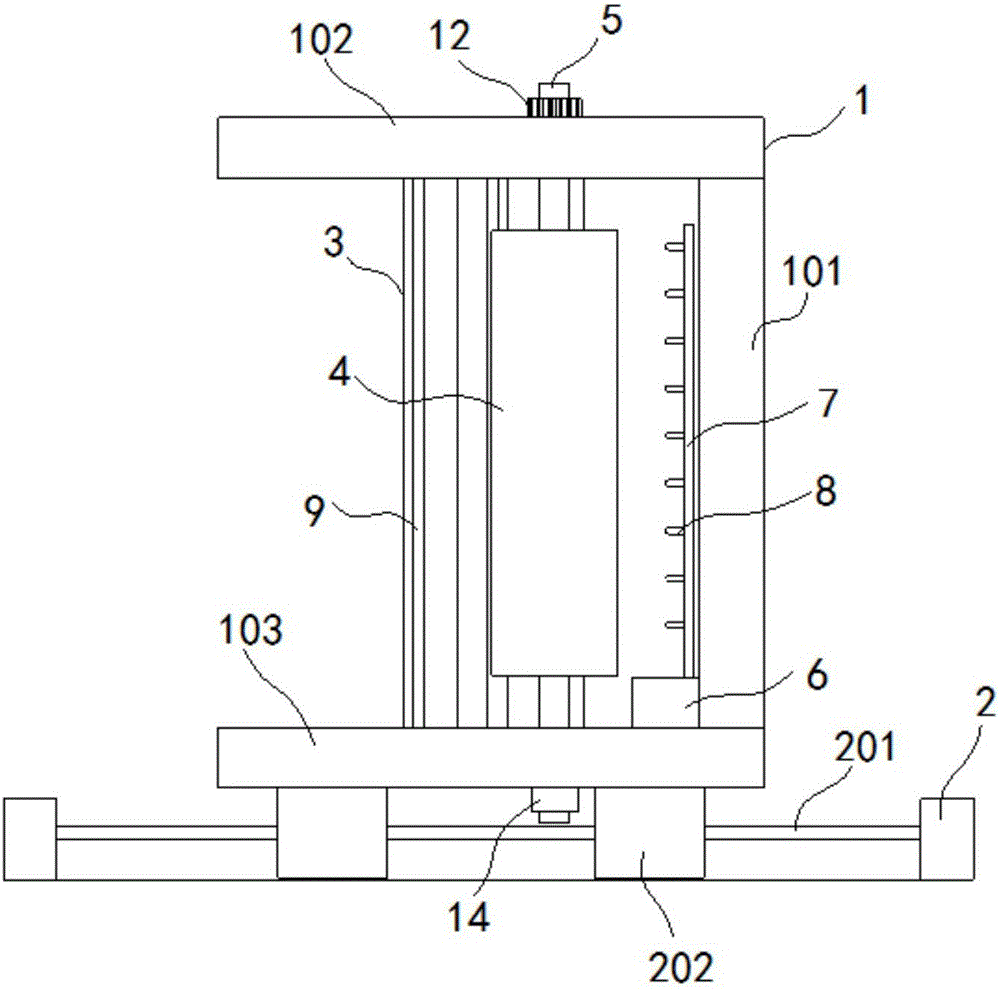

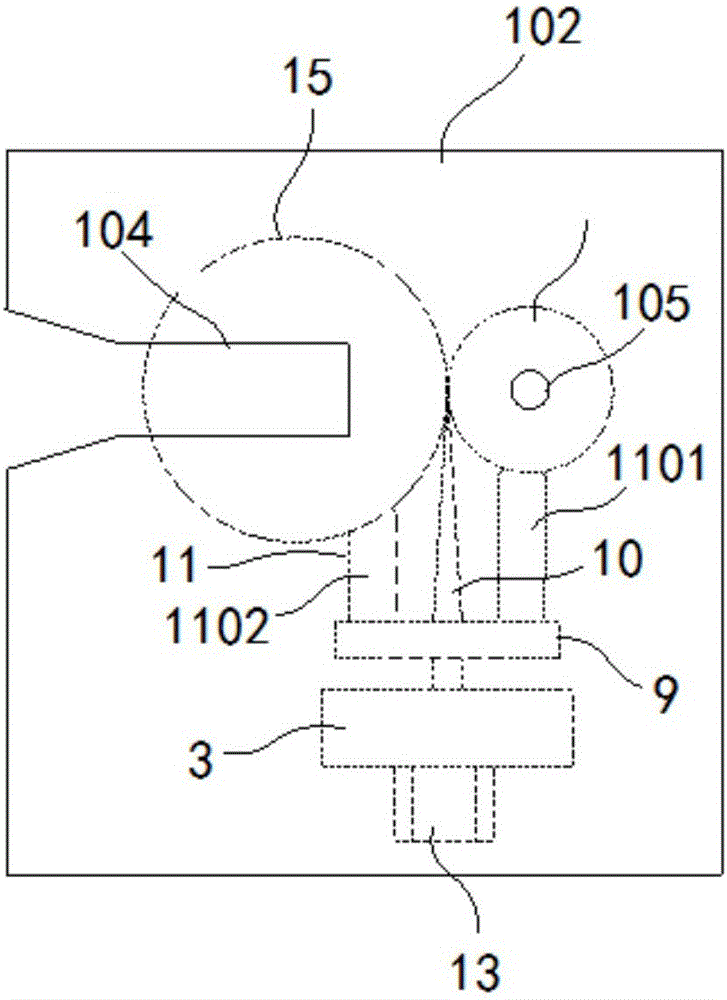

[0028] Such as figure 1 , figure 2 As shown, an automatic packaging and paper cutting device for motor rotors of the present invention includes:

[0029] The positioning frame 1, the positioning frame 1 includes a vertical side plate 101 and a first horizontal plate 102 and a second horizontal plate 103 fixed on the upper and lower ends of the side plate 1, the first horizontal plate 102 and the second horizontal plate A support plate 3 is fixedly arranged between the two horizontal plates 103, the lower end surface of the second horizontal plate 103 is fixedly connected with a sliding device 2, and the front ends of the first horizontal plate 102 and the second horizontal plate 103 are formed with upper and lower Symmetrical positioning slots 104 , vertically symmetrical positioning holes 105 are formed on the rear ends of the first horizontal plate 102 and the second horizontal plate 103 . The sliding device 2 includes a sliding guide rail 201 and a sliding block 202 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com