Gypsum-based self-leveling mortar prepared by taking molybdenum tailings as filler

A technology for self-leveling mortar and molybdenum tailings, which is applied in the field of building materials, can solve the problems of restricting the market promotion of gypsum-based self-leveling mortar, high quality requirements of quartz sand, and increasing production costs, and achieves good strength and leveling. The effect of low volume change rate and increased utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A gypsum-based self-leveling mortar with molybdenum tailings as filler

[0025] In parts by weight, 62 parts of α-gypsum, 35 parts of molybdenum tailings, 0.1 part of defoamer German Mingling P8030.1 part, 0.4 part of water reducing agent German BASF F10, 3 parts of volume stabilizer 525 sulfoaluminate cement, setting time It consists of 0.03 part of citric acid as regulator, 0.1 part of low viscosity HPMC as thickener, and 0.2 part of emulsified paraffin wax (purchased from Ningbo Hansheng Chemical Co., Ltd.) as anti-water agent. Mix the above raw materials at high speed and mix evenly.

Embodiment 2

[0026] Example 2: A gypsum-based self-leveling mortar with molybdenum tailings as filler

[0027] In parts by weight, 67 parts of α gypsum, 30 parts of molybdenum tailings, 0.1 part of defoamer German Mingling P8030.1 part, 0.4 part of water reducing agent German BASF F10, 2 parts of volume stabilizer 525 sulfoaluminate cement, setting time It is composed of 0.03 part of tartaric acid as regulator, 0.1 part of low-viscosity HPMC as thickener, and 1 part of water-resistant agent P.O 42.5 white cement. Mix the above raw materials at high speed and mix evenly.

experiment example 1

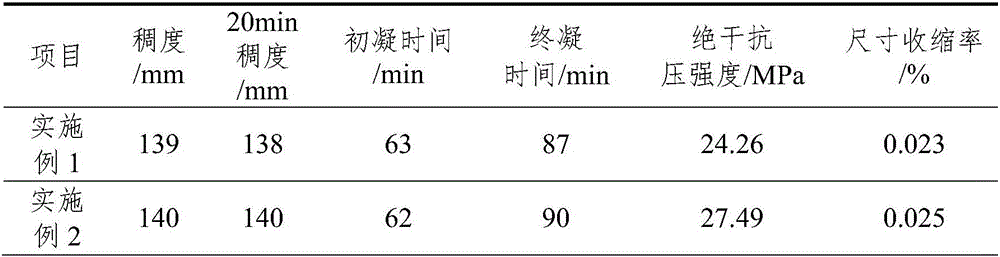

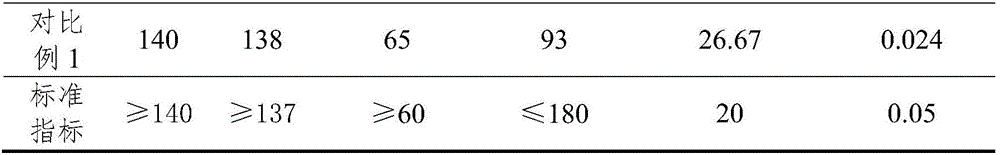

[0031] The gypsum-based self-leveling mortar obtained in Example 1, Example 2, and Comparative Example 1 were mixed with water at a mass ratio of 1:0.35, and the stirring time was 10 minutes. Inject into the mold, let it stand for 2 hours, and detect the cured gypsum, and the performance indicators are shown in Table 1.

[0032] Table 1: Performance Test Results

[0033]

[0034]

[0035] As can be seen from the above table, the initial setting time and final setting time of the gypsum obtained by mixing and solidifying the flat mortar prepared by the scheme of the present invention and water are shorter, and the consistency, dry compressive strength and dimensional shrinkage are comparable to those of The gypsum produced by the existing quartz sand filler flat mortar is equivalent. It can be seen that the flat mortar of the present invention can completely replace the existing flat mortar filled with quartz sand, greatly reduce the production cost of flat drift sand, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com