Iron-based catalyst and preparation method thereof

A technology of iron-based catalysts and iron salts, applied in the field of catalytic chemistry, can solve problems such as restricting wide application, high production costs, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Correspondingly, the present invention also provides a method for preparing an iron-based catalyst, comprising the following steps: adding molecular sieves and silicon oxide to the iron salt solution, stirring to obtain a suspension; evaporating the solvent in the suspension to dryness , and then dried in an oven to obtain a solid; the solid is calcined in an air atmosphere at a calcining temperature of 400-600° C. to obtain an iron-based catalyst.

[0029] As a preferred version, the iron salt solution is preferably an aqueous solution or an alcohol solution of an iron salt, and the solvent in the iron salt solution is selected from water, ethanol, n-propanol, isopropanol, n-butanol, and isobutanol. one or several. In order to improve the reduction degree of metal iron, the iron salt in the iron salt solution is selected from one or more of ferric chloride, iron nitrate, and iron acetate; the mass concentration of the iron salt solution is 10%-40% . In the step of ob...

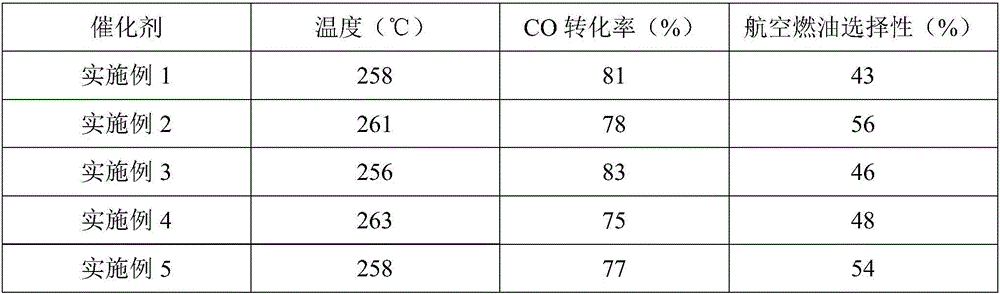

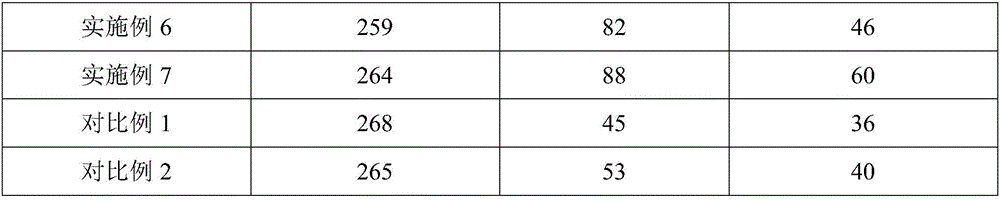

Embodiment 1

[0040] 10Fe / 20SiO 2 Preparation of -70ZSM-35 catalyst:

[0041] Weigh 8.04 g of ferric nitrate nonahydrate, add it into 50 mL of deionized water, and ultrasonically dissolve to obtain ferric nitrate solution. Weigh 7.78g of ZSM-35 molecular sieve with a silicon-aluminum ratio of 15 and 2.22g of silicon dioxide (pore size 10nm), add to the above ferric nitrate solution, and stir at room temperature for 4h. Then the solvent in the above suspension was evaporated to dryness, and the evaporated solid was dried in an oven at 120° C. for 6 h. The dried solid was heated in a muffle furnace to 550 °C at a heating rate of 2 °C / min, and calcined for 5 h in an air atmosphere to obtain the iron-based catalyst 10Fe / 20SiO 2 - 70ZSM-35 in which the iron content is 10% by weight of the catalyst support.

Embodiment 2

[0043] 10Fe / 20SiO 2 Preparation of -70ZSM-5 catalyst:

[0044] Weigh 8.04 g of ferric nitrate nonahydrate, add it into 50 mL of deionized water, and ultrasonically dissolve to obtain ferric nitrate solution. Weigh 7.78g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 25 and 2.22g of silicon dioxide (pore size 10nm), add to the above ferric nitrate solution, and stir at room temperature for 4h. Then the solvent in the above suspension was evaporated to dryness, and the evaporated solid was dried in an oven at 120° C. for 6 h. The dried solid was heated in a muffle furnace to 550 °C at a heating rate of 2 °C / min, and calcined for 5 h in an air atmosphere to obtain the iron-based catalyst 10Fe / 20SiO 2 - 70ZSM-5 in which the iron content is 10% by weight of the catalyst support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com