Ultrasonic cleaning machine for high-speed steel

A technology of ultrasonic cleaning and high-speed steel, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc. It can solve the problems of poor cleaning effect, easy damage, and affecting production efficiency, etc. environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

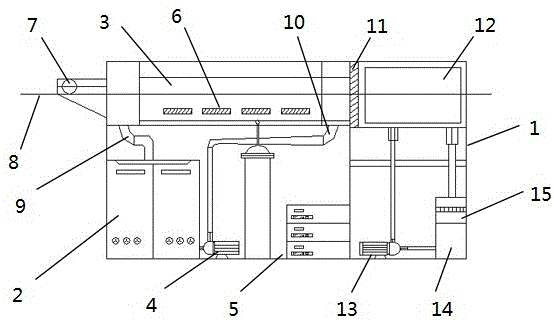

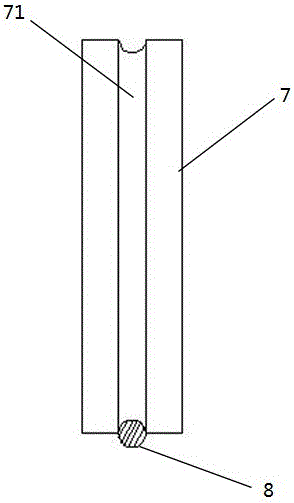

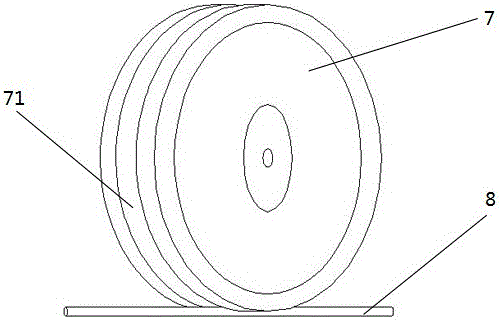

[0022] Embodiment 1: An ultrasonic cleaning machine for high-speed steel, the cleaning machine includes a frame; an ultrasonic cleaning fluid storage tank and an ultrasonic generator are arranged in the frame; an ultrasonic cleaning device is provided at the upper end of the frame tank; the ultrasonic cleaning tank is provided with an ultrasonic vibrating plate; the ultrasonic cleaning liquid storage tank is connected with the ultrasonic cleaning tank through a circulation pump; the left side of the ultrasonic cleaning tank is provided with a high-speed steel feed port; the high-speed A guide roller is provided at the steel feeding port, and the guide roller is used for positioning the high-speed steel; a clear liquid rinsing tank is provided on the right side of the ultrasonic cleaning tank; the high-speed steel enters from the high-speed steel feeding port The ultrasonic cleaning tank passes through the clear liquid rinsing tank; a rinsing liquid storage tank is provided belo...

Embodiment 2

[0024] Embodiment 2: an ultrasonic cleaning machine for high-speed steel, the cleaning machine includes a frame; an ultrasonic cleaning liquid storage tank and an ultrasonic generator are arranged in the frame; an ultrasonic cleaning device is provided at the upper end of the frame tank; the ultrasonic cleaning tank is provided with an ultrasonic vibrating plate; the ultrasonic cleaning liquid storage tank is connected with the ultrasonic cleaning tank through a circulation pump; the left side of the ultrasonic cleaning tank is provided with a high-speed steel feed port; the high-speed A guide roller is provided at the steel feeding port, and the guide roller is used for positioning the high-speed steel; a clear liquid rinsing tank is provided on the right side of the ultrasonic cleaning tank; the high-speed steel enters from the high-speed steel feeding port The ultrasonic cleaning tank passes through the clear liquid rinsing tank; a rinsing liquid storage tank is provided bel...

Embodiment 3

[0026] Embodiment 3: an ultrasonic cleaning machine for high-speed steel, the cleaning machine includes a frame; an ultrasonic cleaning liquid storage tank and an ultrasonic generator are provided in the frame; an ultrasonic cleaning device is provided at the upper end of the frame tank; the ultrasonic cleaning tank is provided with an ultrasonic vibrating plate; the ultrasonic cleaning liquid storage tank is connected with the ultrasonic cleaning tank through a circulation pump; the left side of the ultrasonic cleaning tank is provided with a high-speed steel feed port; the high-speed A guide roller is provided at the steel feeding port, and the guide roller is used for positioning the high-speed steel; a clear liquid rinsing tank is provided on the right side of the ultrasonic cleaning tank; the high-speed steel enters from the high-speed steel feeding port The ultrasonic cleaning tank passes through the clear liquid rinsing tank; a rinsing liquid storage tank is provided bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com