Automatic feeding structure for movable extrusion pads

A squeezing pad and automatic technology, applied in the field of extruders, can solve the problems of increased labor intensity, impossible manual operation, and contamination of particles by the squeezing pad, achieving a high degree of mechanical automation, reducing labor expeditiousness, and saving manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

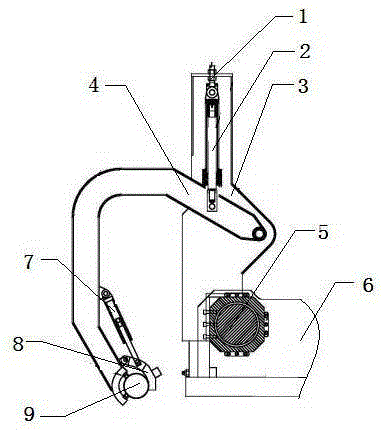

[0011] This embodiment provides an automatic trough-up structure for movable extrusion pads, which is characterized in that: the automatic trough-up structure for movable extrusion pads includes an adjustment bolt (1), a cylinder for gripping pad arms (2), a fixed seat (3), Gripping pad arm (4), fixed plate (5), extruder (6), pad clamping cylinder (7), pad gripping fixture (8), squeeze pad (9);

[0012] Among them: the gripping pad arm fixing seat (3) is fixedly installed on a corner of the extruder (5) through the fixed plate (4), and the gripping pad arm (4) is installed and connected through the gripping pad arm cylinder (2) and the movable pin shaft. The cushion arm cylinder (2) is fixedly installed on the fixed seat (3), and the upper end is also provided with an adjustment bolt (1), and the grasping cushion clamp (8) of the squeezing cushion (9) is arranged under the grasping cushion arm (4), and the grasping cushion One side of the clamp (8) is hingedly mounted with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com