Skid-mounted pressure-testing sewage treatment equipment

A technology for sewage treatment equipment and pressure testing, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc. Solve the problems of high cost to achieve the effects of improved processing efficiency and flexibility, flexible transfer, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

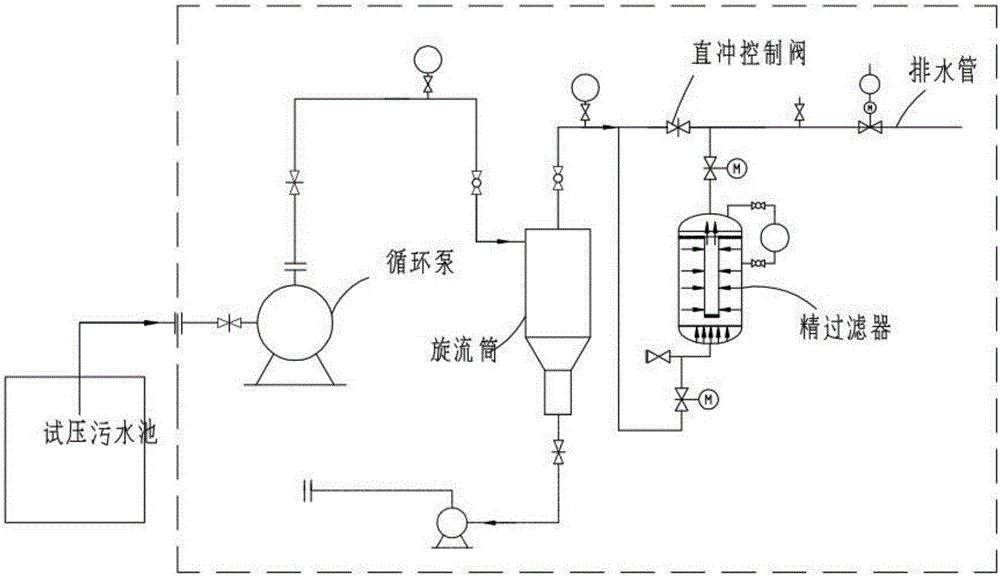

[0022] Embodiment one, such as figure 1 As shown, the present invention provides a skid-mounted pressure test sewage treatment equipment, including a power unit, a coarse filter unit, and a fine filter unit connected in sequence through pipelines, the power unit includes a circulation pump, and the water inlet of the circulation pump is connected to the The water outlet of the pressure test sewage pool is connected, the coarse filter device includes a swirl tube, the water inlet of the coarse filter device is connected with the water outlet of the power unit, the water outlet of the coarse filter device is connected to a drain pipe, and the drain pipe is equipped with The direct flush control valve, the water inlet of the fine filter device is connected to the drain pipe at the front end of the direct flush control valve, the water outlet of the fine filter device is connected to the drain pipe at the rear end of the direct flush control valve, and the fine filter device includ...

Embodiment 2

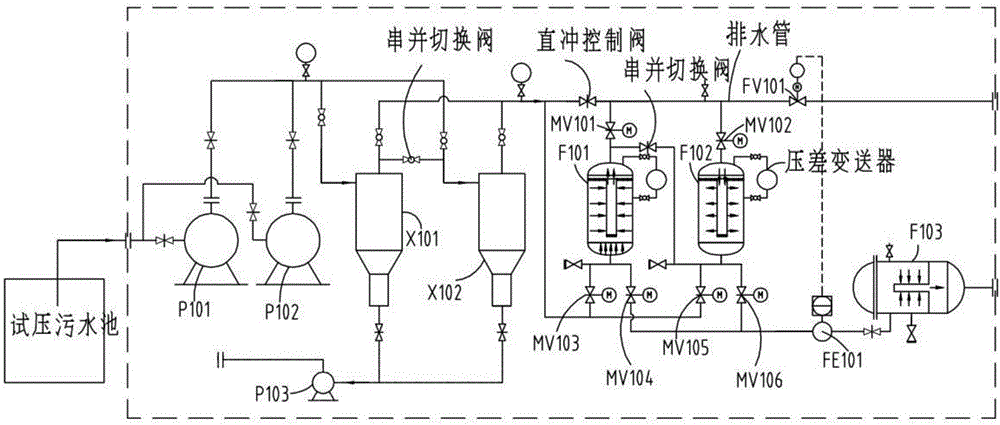

[0023] Embodiment two, such as figure 2 As shown, for the sake of illustration, figure 2 The two circulating pumps are P101 and P102, the two cyclone cylinders are X101 and X102, the slurry pump is P103, the two fine filters are F101 and F102, the flushing filter is F103, the flow regulating valve is FV101, and the two The electric gate valves between the water outlets of the fine filters F101 and F102 and the drain pipes are MV101 and MV102 respectively; the electric gate valves between the water inlets of the two fine filters F101 and F102 and the drain pipes are respectively MV103 and MV104; the two fine filters F101 , F102 water inlet and flushing filter F103 water inlet are respectively MV105 and MV106. The water inlet of the flushing filter F103 is also provided with a flow meter FE101.

[0024] The power device is two parallel circulations P101 and P102, a stop valve is installed between the water inlet of each circulation pump and the water outlet of the pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com