Novel non-magnetic stainless steel

A new type of non-magnetic stainless steel technology, applied in the field of alloy materials, can solve the problems of increased cost, insufficient corrosion resistance and wear resistance, and no antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

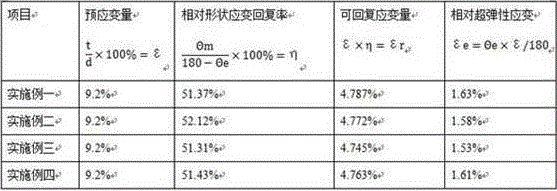

Examples

Embodiment 1

[0022] A new type of non-magnetic stainless steel, the components of the new type of non-magnetic stainless steel are calculated by weight percentage (the following % all represent weight percentages): carbon is 0.15%, nickel is 6%, chromium is 13%, manganese is 9%, Niobium is 0.62%, vanadium is 0.28%, molybdenum is 1.5%, titanium is 3.7%, rare earth is 0.53%, silver is 0.13%, copper is 0.7%, the total amount of phosphorus and sulfur is not more than 0.035%, and the balance is iron and its unavoidable impurities, the novel non-magnetic stainless steel is produced through the following steps:

[0023] Step 1. Use a medium-frequency induction furnace for smelting. Put the raw iron into the converter to heat and melt it. After the raw iron is completely melted, adjust the temperature of the molten pool so that the temperature of the molten pool is controlled at about 1580°C, and then add a decarburizer into the molten pool. , desulfurizer, deoxidizer, decarburization, desulfuriza...

Embodiment 2

[0033]A new type of non-magnetic stainless steel, the components of the new type of non-magnetic stainless steel are calculated by weight percentage (the following % all represent weight percentages): carbon is 0.18%, nickel is 3.15%, chromium is 8.71%, manganese is 11.8%, 4.80% silicon, 0.57% niobium, 0.23% vanadium, 1.5% molybdenum, 3.56% titanium, 0.31% rare earth, the total amount of phosphorus and sulfur does not exceed 0.035%, and the balance is iron and its unavoidable impurities , the novel non-magnetic stainless steel is made through the following steps:

[0034] Step 1. Use a medium-frequency induction furnace for smelting. Put the raw iron into the converter to heat and melt it. After the raw iron is completely melted, adjust the temperature of the molten pool so that the temperature of the molten pool is controlled at about 1580°C, and then add a decarburizer into the molten pool. , desulfurizer, deoxidizer, decarburization, desulfurization and deoxidation of molte...

Embodiment 3

[0044] A new type of non-magnetic stainless steel, the composition of the new type of non-magnetic stainless steel is calculated by weight percentage (the following % all represent weight percentage): carbon is 0.21%, nickel is 3%, chromium is 13%, manganese is 11%, 5% silicon, 0.48% niobium, 0.13% vanadium, 1.7% molybdenum, 4% titanium, 0.27% rare earth, the total amount of phosphorus and sulfur does not exceed 0.035%, and the balance is iron and its unavoidable impurities , the novel non-magnetic stainless steel is made through the following steps:

[0045] Step 1. Use a medium-frequency induction furnace for smelting. Put the raw iron into the converter to heat and melt it. After the raw iron is completely melted, adjust the temperature of the molten pool so that the temperature of the molten pool is controlled at about 1580°C, and then add a decarburizer into the molten pool. , desulfurizer, deoxidizer, decarburization, desulfurization and deoxidation of molten iron in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com